Method for extracting pigment from eleochairis toberosa peel

A water chestnut skin and pigment technology, applied in chemical instruments and methods, azo dyes, organic dyes, etc., can solve the problems of unfavorable preservation, complex components, low color scale, etc., to maintain the original biological activity, broad development prospects, The effect of high pigment quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

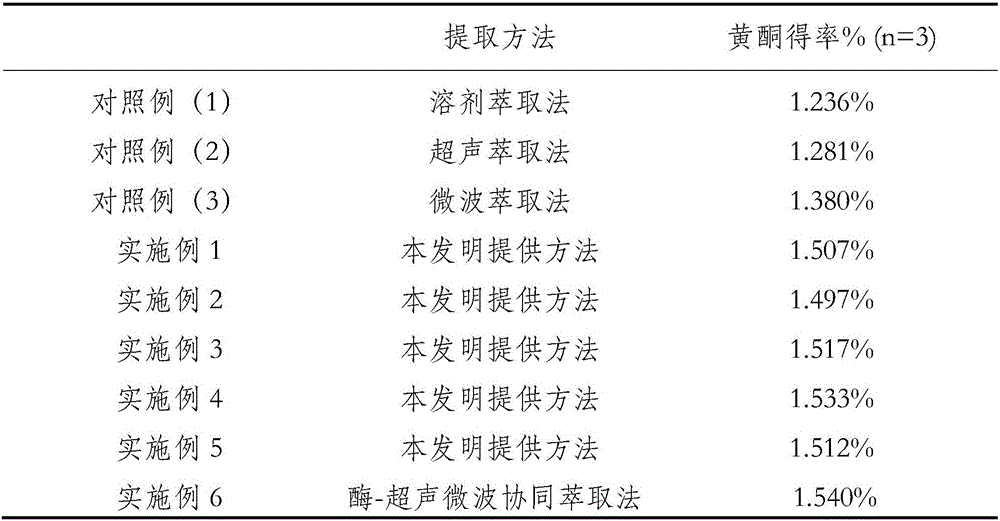

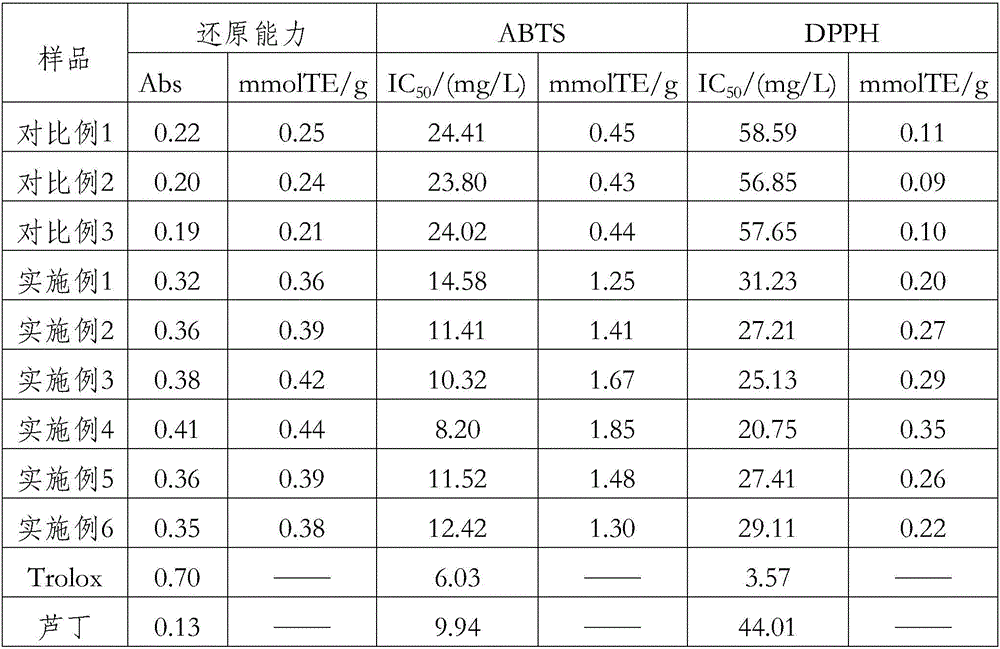

Examples

Embodiment 1

[0023] Wash the water chestnut skin, remove dust and impurities on the surface, remove the rotten part, dry it in an oven at 30°C to constant weight, crush it, and pass it through a 40-mesh sieve. Weigh 2g of water chestnut skin, add an appropriate amount of sodium dihydrogen phosphate buffer solution with a solid-liquid ratio of 1:15, add a compound enzyme of cellulase and pectinase with a total mass of water chestnut skin dry powder of 1.2% for enzymolysis, wherein The ratio of cellulase and pectinase was 1:2, stirred and reacted at 55°C and 750rpm for 2h, centrifuged at 7000rpm for 25min, and filtered. Take the water chestnut skin dregs after enzymatic hydrolysis, add a 70% ethanol solution to it, and add according to the mass ratio of water chestnut skin dry powder to liquid: 1:20. Ultrasonic and microwave synergistic extraction is carried out, wherein the extraction conditions are: ultrasonic fixed frequency 40KHz, power 50W, microwave power 250W, and extraction time 90s....

Embodiment 2

[0025] Wash the water chestnut skin, remove dust and impurities on the surface, remove the rotten part, dry it in an oven at 30°C to constant weight, crush it, and pass it through a 40-mesh sieve. Weigh 2g of water chestnut skin, add an appropriate amount of sodium dihydrogen phosphate buffer solution with a solid-liquid ratio of 1:15, add a compound enzyme of cellulase and pectinase with a total mass of water chestnut skin dry powder of 1.2% for enzymolysis, wherein The ratio of cellulase and pectinase is 1:2, stirred and reacted at 50-55°C and 700-850rpm for 1-3h, centrifuged at 7000-8000rpm for 15-25min, and filtered. Take the water chestnut skin dregs after enzymatic hydrolysis, add a 70% ethanol solution to it, and add according to the mass ratio of water chestnut skin dry powder to liquid: 1:20. Ultrasonic and microwave synergistic extraction is carried out, wherein the extraction conditions are: ultrasonic fixed frequency 40KHz, power 50W, microwave power 150W, and extr...

Embodiment 3

[0027] Wash the water chestnut skin, remove dust and impurities on the surface, remove the rotten part, dry it in an oven at 30°C to constant weight, crush it, and pass it through a 40-mesh sieve. Weigh 2g of water chestnut skin, add an appropriate amount of sodium dihydrogen phosphate buffer solution with a solid-liquid ratio of 1:15, add a compound enzyme of cellulase and pectinase with a total mass of water chestnut skin dry powder of 1.2% for enzymolysis, wherein The ratio of cellulase and pectinase is 1:1, stirred and reacted at 50°C and 850pm for 2h, centrifuged at 8000rpm for 15min, and filtered. Take the water chestnut skin dregs after enzymatic hydrolysis, add a 70% ethanol solution to it, and add according to the mass ratio of water chestnut skin dry powder to liquid: 1:20. Ultrasonic and microwave synergistic extraction is carried out, wherein the extraction conditions are: ultrasonic fixed frequency 40KHz, power 50W, microwave power 250W, and extraction time 90s. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com