Special powder paint for outdoor metal guardrail

A powder coating and guardrail technology, applied in powder coatings, anti-corrosion coatings, coatings, etc., can solve the problems of coating powder and peeling, the coating is easy to scratch the human body, and the appearance of the guardrail is affected, and the corrosion rate is slow and excellent. Adhesion, avoid chalking and peeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Add 3 parts of bismaleimide resin and 3 parts of hydrogenated rosin pentaerythritol ester to 20 parts of thermosetting acrylic resin, and heat up to 130-135 ° C at a heating rate of 5 ° C / min and mix for 20 minutes, then add 1 1 part of sepiolite fiber, 0.5 part of N-methylolacrylamide and 0.5 part of dilauryl thiodipropionate, continue to mix at 130-135 ° C for 10 minutes, and then naturally cool to room temperature to obtain material I;

[0024] (2) Add 2 parts of C5 hydrogenated petroleum resin and 1 part of waste tire rubber powder to 10 parts of aromatic hydrocarbon modified terpene resin, and heat up to 100-105 °C at a heating rate of 5 °C / min and mix for 15 minutes, then add 0.5 parts of polydimethyldiallyl ammonium chloride and 0.3 parts of tris (2-chloroethyl) phosphate, continue to heat up to 125-130 ° C at a heating rate of 5 ° C / min and mix for 15 min, then naturally cool to At room temperature, the material II is obtained;

[0025] (3) Add material...

Embodiment 2

[0029] (1) Add 3 parts of bismaleimide resin and 2 parts of hydrogenated rosin pentaerythritol ester to 20 parts of thermosetting acrylic resin, and heat up to 130-135 °C at a heating rate of 5 °C / min and mix for 20 minutes, then add 1 1 part of sepiolite fiber, 1 part of N-methylolacrylamide and 0.5 part of dilauryl thiodipropionate, continue to mix at 130-135 ° C for 10 minutes, and then naturally cool to room temperature to obtain material I;

[0030] (2) Add 2 parts of C5 hydrogenated petroleum resin and 2 parts of waste tire rubber powder to 10 parts of aromatic hydrocarbon modified terpene resin, and heat up to 100-105 °C at a heating rate of 5 °C / min and mix for 15 minutes, then add 1 part of polydimethyldiallyl ammonium chloride and 0.3 part of tris (2-chloroethyl) phosphate, continue to heat up to 125-130 ° C at a heating rate of 5 ° C / min and mix for 15 min, then naturally cool to At room temperature, the material II is obtained;

[0031] (3) Add material II, 2 pa...

Embodiment 3

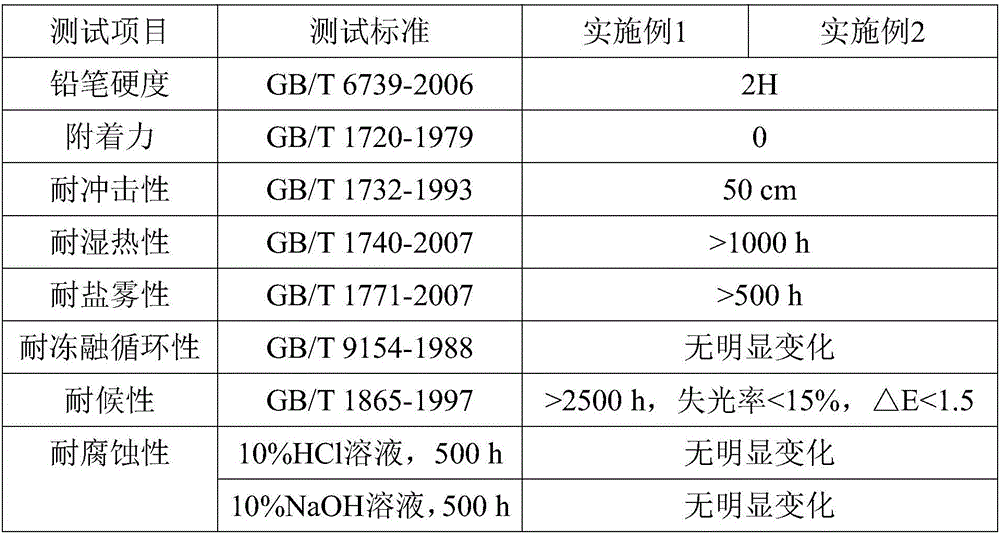

[0035] The powder coatings prepared in Example 1 and Example 2 were sprayed on the metal guardrail by electrostatic spraying technology, and the service performance test of the formed coating was carried out. The test results are shown in Table 1.

[0036] The performance of the powder coating prepared by the embodiment of the present invention in table 1

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com