Crude oil desalting method based on coupling of solvent extraction and electric desalting

An electric desalination and extraction technology, which is applied in the petroleum industry, hydrocarbon oil treatment, and multi-stage series-connected refining process treatment, etc., can solve the problems of insignificant desalination and dehydration effect of crude oil, complicated synthesis steps of desalting agent, and complicated preparation of compound agent. , to achieve the effect of a wide range of applications, low requirements and good solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

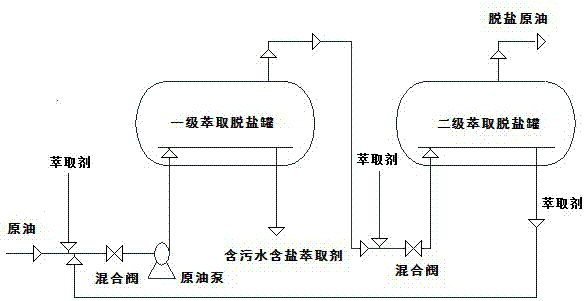

[0039] see figure 1 . A crude oil desalting method based on the coupling of solvent extraction and electric desalting, using heavy crude oil from Shengli Oilfield (crude oil density: 0.9040-0.9660g / cm 3 ) and Qilu Petrochemical’s high-density extra-heavy crude oil (crude oil density: ﹥0.9660g / cm 3 ), the physical properties of the two batches of crude oil are shown in Table 2.

[0040] Table 2. The physical property of the crude oil that embodiment 1 adopts

[0041] .

[0042] Contains the following steps:

[0043] (1) Inject the extractant

[0044] Use the high solubility of the extractant to salt to remove the salt contained in the crude oil: inject ethylene glycol (or use ethylene glycol, glycerol, 1,2-propanediol, 1,3- One or more of propylene glycol, diethylene glycol monomethyl ether, propylene glycol methyl ether, dipropylene glycol dimethyl ether, dimethylamine, dipropylamine, cyclopropylamine, diisobutylamine), the crude oil and ethylene glycol are The mass r...

Embodiment 2

[0056] see figure 1 . A crude oil desalting method based on the coupling of solvent extraction and electric desalting, the processed crude oil is the same as that in Example 1.

[0057] Contains the following steps:

[0058] (1) Inject the extractant

[0059] Inject glycerol (or 1,2-propanediol, 1,3-propanediol, diethylene glycol monomethyl ether, propylene glycol methyl ether, dipropylene glycol dimethyl ether, dimethylamine, dipropylamine, cyclopropylamine) into the crude oil , one or more of diisobutylamine); the crude oil and glycerol are fully mixed through a mixing valve at a mass ratio of 9:1 and then entered into a first-stage extraction and desalination tank.

[0060] (2) Primary extraction and desalination

[0061] Use an extraction temperature of 110°C, use a weak electric field of 600V / cm and a strong electric field of 1500V / cm for desalination, the electric field can be AC, DC or pulse electric field; stay in the weak electric field for 60 minutes, stay in the...

Embodiment 3

[0077] see figure 1 . A crude oil desalting method based on the coupling of solvent extraction and electric desalting, the processed crude oil is the same as that in Example 1.

[0078] Contains the following steps:

[0079] (1) Inject the extractant

[0080] Inject 1,2-propanediol and 1,3-propanediol (or diethylene glycol monomethyl ether, propylene glycol methyl ether, dipropylene glycol dimethyl ether, dimethylamine, dipropylamine, cyclopropylamine, diisobutyl One or more amines); the crude oil is fully mixed with 1,2-propanediol and 1,3-propanediol at a ratio of 20:0.5+0.5, and then enters the primary extraction and desalination tank.

[0081] (2) Primary extraction and desalination

[0082] Use an extraction temperature of 160°C, use a weak electric field of 450V / cm and a strong electric field of 750V / cm for desalination, and the electric field can use AC, DC or pulse electric field; stay in the weak electric field for 20 minutes, stay in the strong electric field for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com