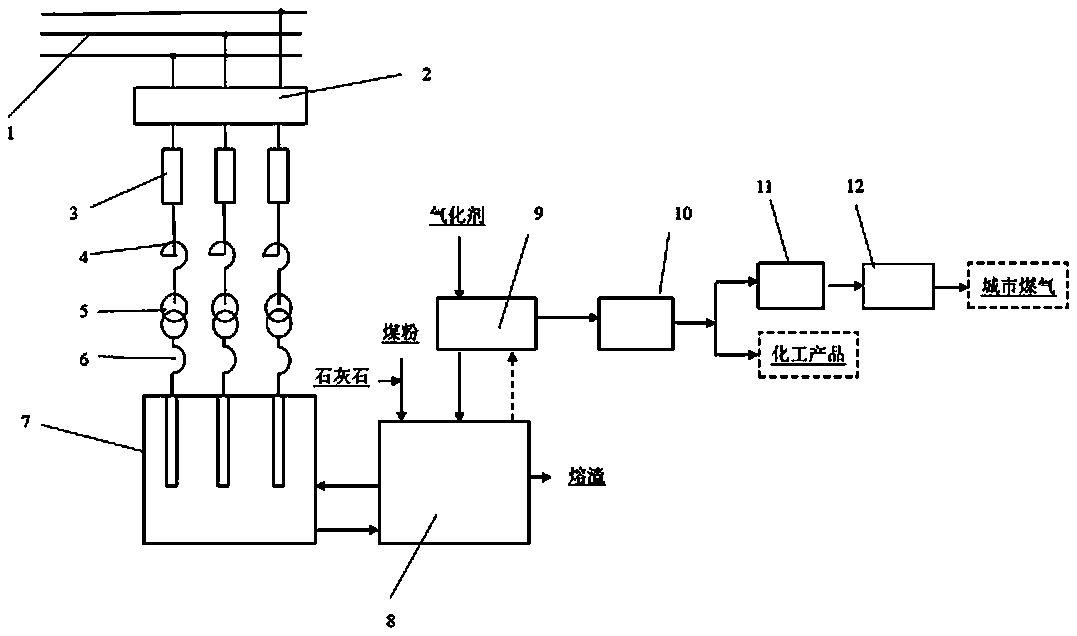

A grid peak-shaving system and method for electric arc furnace double-chamber iron bath coal gasification

A technology of electric arc furnace and coal gasification, which is applied in gasification process, gasification catalyst, molten salt/molten metal gasification and other directions, can solve problems such as affecting the service life of generator sets, increasing energy consumption, and reducing economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

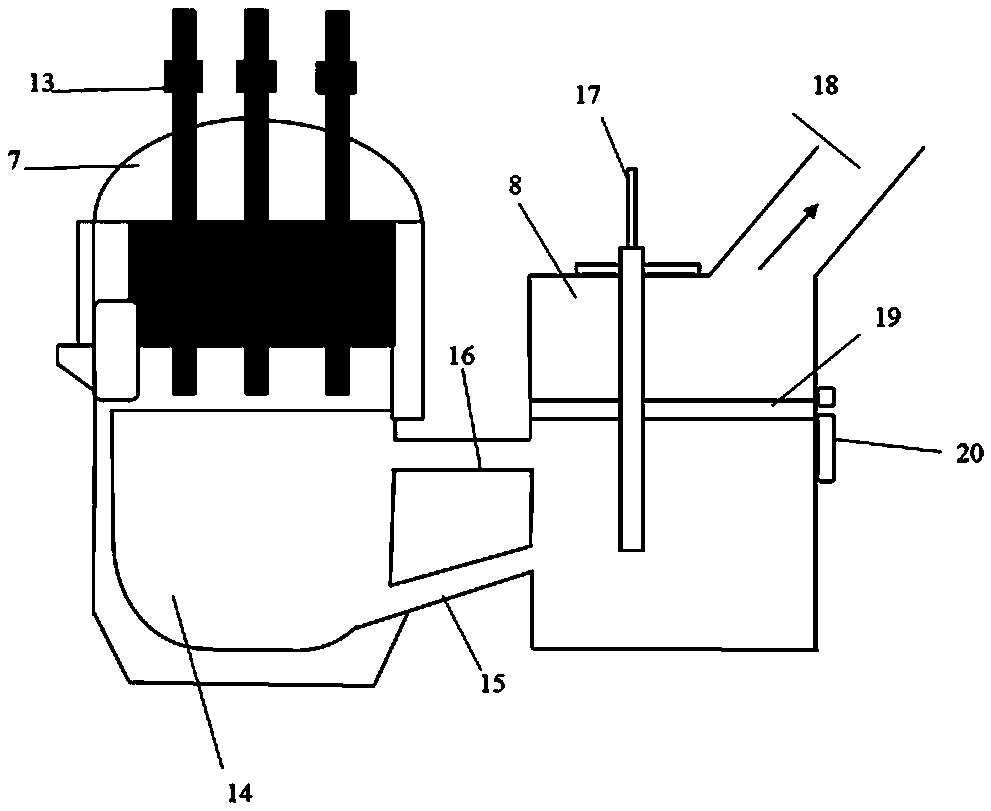

[0098] A power grid peak-shaving method for electric arc furnace double-chamber iron-bath coal gasification, which adopts such figure 1 The power grid peak regulation system shown, the system adopts such as image 3 The iron-smelting electric arc furnace and the coal gasifier shown: the capacity of molten iron is 150t, the diameter of the bottom surface is 2m, the height is 6m, and the depth of molten iron is 3.1m; the power grid peak regulation method includes the following steps:

[0099] (1) According to the actual power consumption in the off-peak period, determine the peak-shaving amount of the power grid and set the power load;

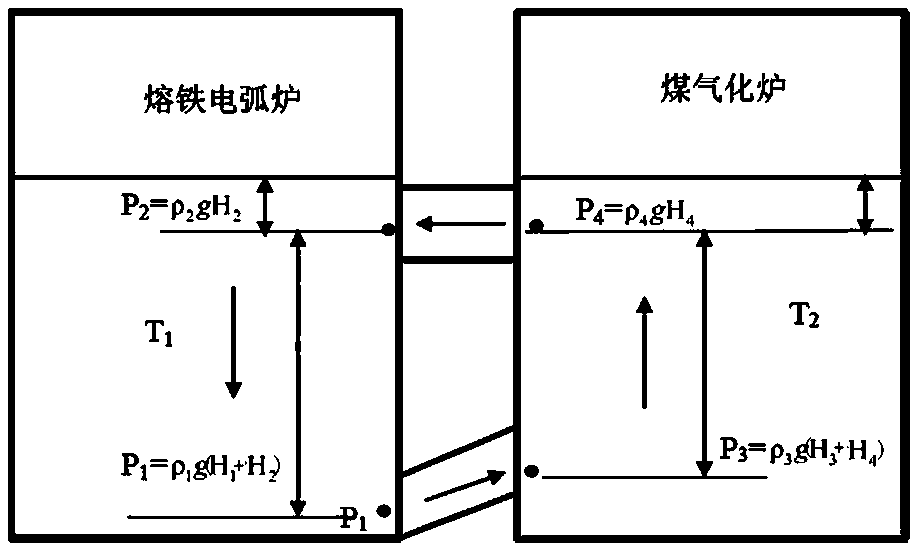

[0100] (2) The electric current is introduced into the iron-smelting electric arc furnace to heat the molten iron. The temperature in the iron-smelting electric arc furnace is 1550°C, and the temperature in the coal gasifier is 1450°C. The molten iron forms a circulating flow between the iron-smelting electric arc furnace and the coal gasifier; ...

Embodiment 2

[0106] A power grid peak-shaving method for electric arc furnace double-chamber iron-bath coal gasification, which adopts such figure 1 The power grid peak regulation system shown, the system adopts such as Figure 4 The molten iron electric arc furnace and coal gasifier shown in the figure: the capacity of molten iron is 150t, the diameter of the bottom surface is 2m, the height is 6m, the depth of molten iron is 3.1m, and the angle between the material nozzle in the coal gasifier and the side wall of the coal gasifier is 30°; The power grid peak regulation method includes the following steps:

[0107] (1) According to the actual power consumption in the off-peak period, determine the peak-shaving amount of the power grid and set the power load;

[0108] (2) Introduce electric current into the molten iron electric arc furnace to heat the molten iron, wherein the temperature in the iron molten electric arc furnace is 1500°C, and the temperature in the coal gasifier is 1400°C,...

Embodiment 3

[0114]A power grid peak-shaving method for electric arc furnace double-chamber iron-bath coal gasification, which adopts such figure 1 Multiple sets of power grid peak regulation systems are shown, and the multiple sets of systems all adopt the following image 3 The molten iron electric arc furnace and the coal gasification furnace shown: the capacity of molten iron is 150t, the diameter of the bottom surface is 2m, the height is 6m, and the depth of molten iron is 3.1m; the power grid peak regulation method includes the following steps:

[0115] (1) Determine the peaking amount of the power grid according to the actual power consumption in the off-peak period, set the power load, and connect multiple sets of power grid peaking systems in parallel;

[0116] (2) Introduce current into each iron-smelting electric arc furnace in the parallel system to heat molten iron. The temperature in the iron-smelting electric arc furnace is 1500°C, and the temperature in the coal gasifier i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com