A silicon wafer cutting fluid

A silicon wafer cutting fluid, integer technology, applied in lubricating compositions, petroleum industry, etc., can solve the problems of mortar deposition, silicon wafer surface damage, high energy consumption, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

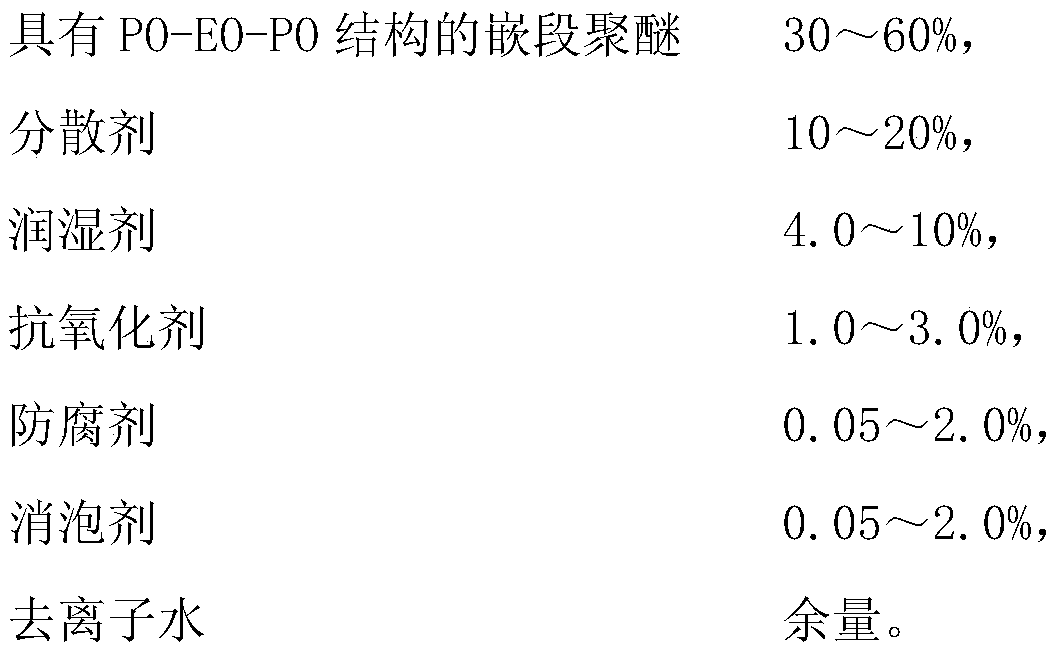

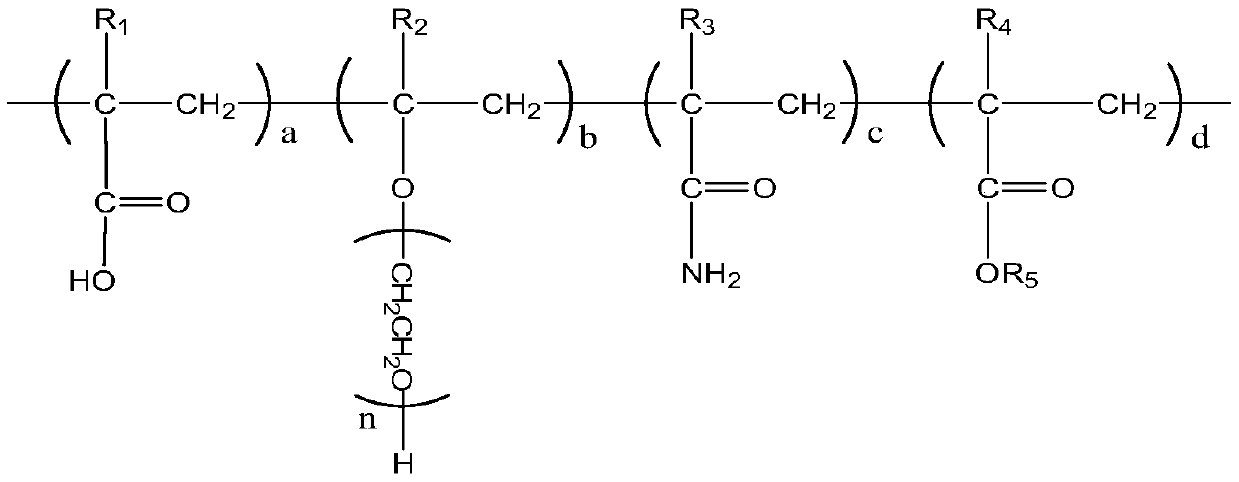

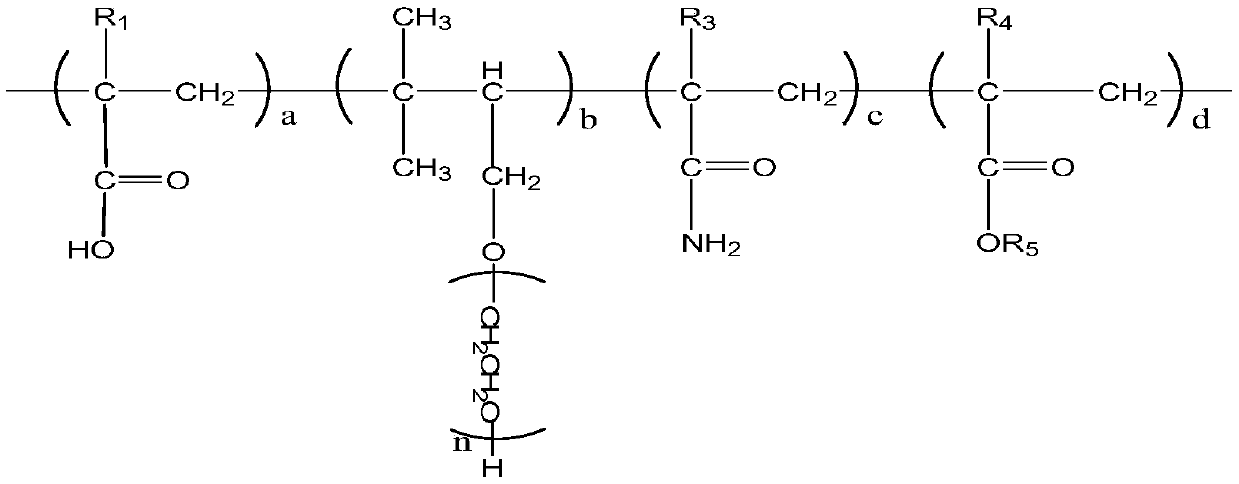

[0039] Prepare 1000g of cutting fluid, and the ratio of each component is as follows: block polyether (R is methoxy, n=20, m+q=10) 300g, comb structure dispersant (R 1 , R 2 , R 3 , R 4 for -H,R 5 for -CH 3 , n=10, a=5, b=5, c=5, d=5) 200g, JFC-6100g, ascorbic acid 20g, isothiazolone 20g, silicone defoamer 10g, deionized water 350g.

[0040] Add deionized water into the flask, start the stirrer at room temperature, slowly add the above-mentioned amount of block polyether, allyl polyoxyethylene ether-acrylic acid polymer, JFC-6, ascorbic acid, isothiazolinone, silicone defoaming agent, and continue to stir for 40 minutes to obtain cutting fluid No. 1. Its performance indicators are shown in the attached table.

Embodiment 2

[0042] Prepare 1000g of cutting fluid, and the ratio of each component is as follows: block polyether (R is ethoxy, n=50, m+q=40) 600g, comb structure dispersant (R 1 , R 2 , R 3 , R 4 for -CH 3 , R 5 for -CH 2 CH 3, n=50, a=30, b=30, c=30, d=30) 100g, sulfonated oil 40g, dibutylhydroxytoluene 1g, sodium benzoate 0.5g, polyether modified silicone oil defoamer 0.5g , Deionized water 258g.

[0043] Add deionized water into the flask, start the stirrer at room temperature, slowly add the above-mentioned amount of block polyether, methallyl polyoxyethylene ether-acrylic acid-methacrylate polymer, sulfonated oil, dibutyl hydroxytoluene, sodium benzoate, polyether modified silicone oil defoamer, and continue to stir for 40 minutes to obtain cutting fluid No. 2. Its performance indicators are shown in the attached table.

Embodiment 3

[0045] Prepare 1000g of cutting fluid, and the ratio of each component is as follows: block polyether (R is propoxy, n=80, m+q=70) 500g, comb structure dispersant (R 1 , R 2 for -H,R 3 , R 4 for -CH 3 , R 5 for -CH 3 , n=30, a=18, b=18, c=18, d=18) 150g, fast penetrating agent T 70g, tea polyphenol 10g, potassium sorbate 10g, higher alcohol defoamer 5g, deionized water 255g.

[0046] Add deionized water into the flask, start the stirrer at room temperature, and slowly add the above-mentioned amount of block polyether, allyl polyoxyethylene ether-methacrylic acid-acrylamide polymer, rapid penetrant T, tea polyphenol , potassium sorbate, and high-carbon alcohol defoamer, and continued to stir for 40 minutes to obtain cutting fluid No. 3. Its performance indicators are shown in the attached table.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com