Method for synchronously extracting grease and antioxidative peptide from soybeans

A technology for synchronous extraction of antioxidant peptides, which is applied in fat oil/fat production, fat production, fermentation, etc., can solve the problems of long time consumption, low yield, high cost, etc., and achieve safe operation, simple equipment, and high added value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

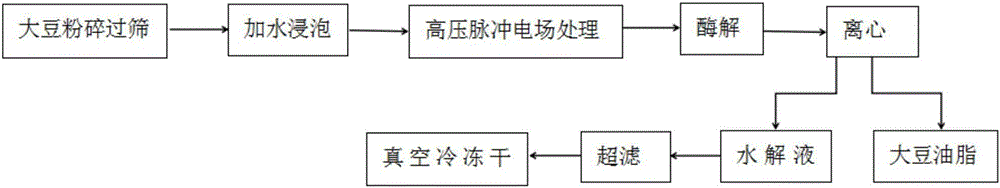

Method used

Image

Examples

Embodiment 1

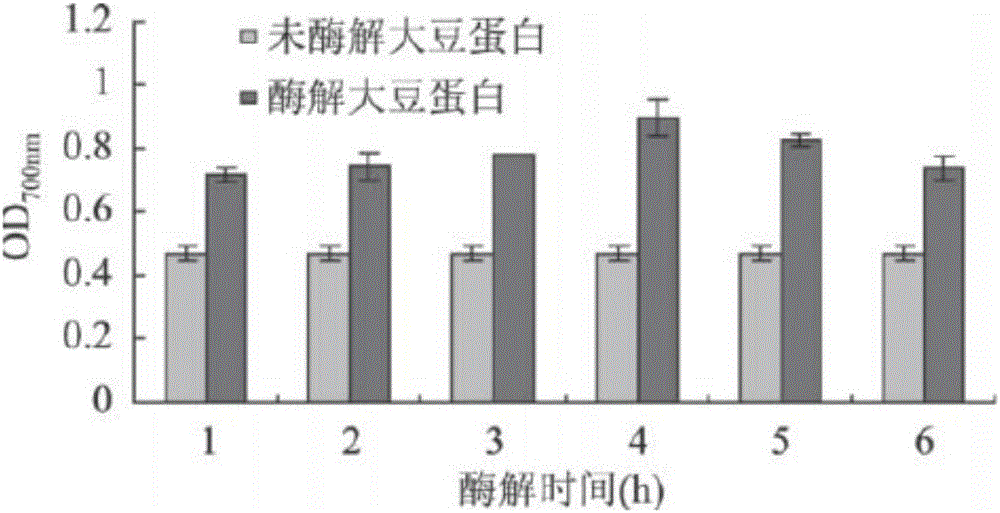

[0020] Specific steps for the determination of the antioxidant polypeptide reducing ability: dissolve 10 mg of the sample in 1 mL of distilled water, add 2.5 mL of 0.2 mol / L PBS (pH 6.6) and 2.5 mL of 1% potassium ferricyanide solution and mix well, and mix well from the above Take 1 mL of the mixed solution, then add 0.2 mL of 0.1% ferric chloride solution and mix well, then add 1 mL of distilled water and shake well, adjust to zero with distilled water, and measure the absorbance at 700 nm. The higher the absorbance, the stronger the reducing ability of the sample.

[0021] attached by figure 1 It can be seen that the reducing ability of soybean protein enzymatic hydrolyzate is greater than that of unenzymolyzed soybean protein, and the reducing ability of enzymatic hydrolyzate reaches the maximum at 4h, the former is 1.91 times of the latter. After 4 hours of enzymatic hydrolysis, the reducing ability of the enzymatic hydrolyzate gradually decreased. The reason may be that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com