Green method for increasing enzymolysis efficiency of cellulose in rice straws through stepwise pretreatment with two deep co-melting solvents

A technology of deep eutectic solvent and rice straw, applied in fermentation and other directions, can solve the problems of poor pretreatment effect and low utilization efficiency, and achieve the effects of improving utilization rate, improving glucose yield, and enhancing enzymatic hydrolysis efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

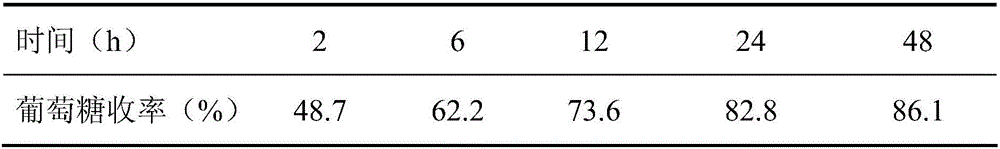

[0022] Using choline chloride / oxalic acid (molar ratio 2:1, deep eutectic solvent A) and choline chloride / urea (molar ratio 1:2, deep eutectic solvent B) in two steps to improve rice straw enzymes solution efficiency

[0023]a) Pretreatment: Accurately weigh 300mg of rice straw powder (the rice straw is dried and crushed into rice straw powder with an average particle size of 150-350μm) and 6g of choline chloride / oxalic acid at a molar ratio of 2:1. Deep eutectic solvent A, put together in a 25mL Erlenmeyer flask, reflux and stir at 120°C for 2 hours; then cool to room temperature, add 6g of warm water to dilute, filter, then wash the filter residue with 18g of deionized water for 4 times, and dry the filter residue , and then add 6g of choline chloride / urea with a molar ratio of 1:2 deep eutectic solvent B and put them together in a 25mL Erlenmeyer flask, reflux and stir at 120°C for 2 hours; then cool to room temperature, add 6g of warm water to dilute, After filtering, the...

Embodiment 2

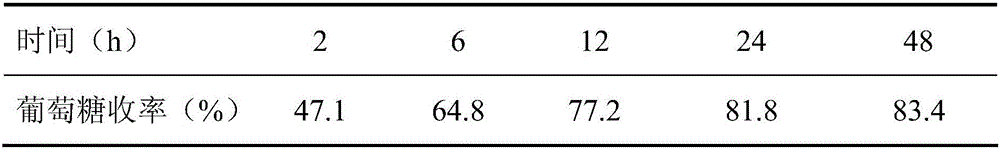

[0028] Improve rice straw enzymes by pretreatment with choline chloride / urea (molar ratio 1:2, deep eutectic solvent B) and choline chloride / oxalic acid (molar ratio 2:1, deep eutectic solvent A) solution efficiency

[0029] a) Pretreatment: Accurately weigh 300 mg of rice straw powder (the rice straw is dried and crushed into rice straw powder with an average particle size of 150-350 μm) and 6 g of deep eutectic solvent B, and place them together in a 25 mL Erlenmeyer flask. Reflux and stir at 120°C for 2 hours; then cool to room temperature, add 6g of warm water to dilute and filter, then wash the filter residue with 18g of deionized water for 4 times, after the filter residue is dried, add 6g of deep eutectic solvent A and place it in a 25mL triangular In the bottle, reflux and stir at 120 ° C for 2 hours; then cool to room temperature, add 6 g of warm water to dilute, filter, and then wash the filter residue with 18 g of deionized water for 4 times, and dry the filter resi...

Embodiment 3

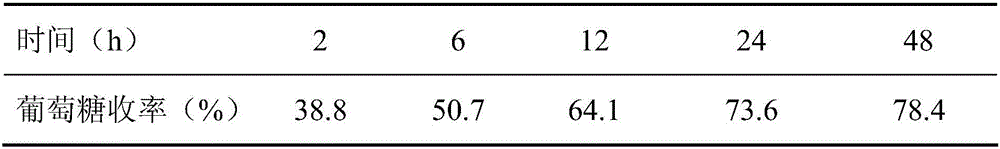

[0046] Malic acid / proline (molar ratio 1:3, deep eutectic solvent A) and choline chloride / urea (molar ratio 1:2, deep eutectic solvent B) were pretreated in two steps to improve rice straw enzymes solution efficiency

[0047] a) Pretreatment: Accurately weigh 300mg of rice straw powder (the rice straw is dried and crushed into rice straw powder with an average particle size of 150-350μm) and 6g of malic acid / proline with a molar ratio of 1:3 Eutectic solvent A, put together in a 25mL Erlenmeyer flask, reflux and stir at 120°C for 6 hours; then cool to room temperature, add 6g of warm water to dilute, filter, and then wash the filter residue with 18g of deionized water for 4 times, and then dry the filter residue Add 6g of choline chloride / urea deep eutectic solvent B with a molar ratio of 1:2, put them in a 25mL Erlenmeyer flask, reflux and stir at 120°C for 6 hours; then cool to room temperature, add 6g of warm water to dilute and filter, The filter residue was washed 4 time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com