Bionic-structure cubic boron nitride coating and preparation method thereof

A cubic boron nitride and boron nitride layer technology, applied in the coating, metal material coating process, superimposed layer plating and other directions, can solve the problems of insufficient fracture toughness and high residual stress of the cubic boron nitride coating, To achieve the effect of reducing residual stress, enhancing fracture toughness, and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] Correspondingly, the embodiment of the present invention also provides a method for preparing a cubic boron nitride coating with a biomimetic structure, comprising the following steps:

[0027] S01. Provide a base;

[0028] S02. Depositing M1B on said substrate x : M2 doped composite layer, in the M1B x : Deposit the M2 layer on the M2 doped composite layer; repeat the deposition M1B x : the step of M2 doping composite layer and M2 layer to obtain M1B x : A multi-layer composite structure formed by alternate deposition of M2 doped composite layer and M2 layer;

[0029] S03. Depositing a cubic boron nitride layer on the multilayer composite structure.

[0030] Specifically, in the above step S01, the substrate described in the embodiment of the present invention is the substrate to be deposited with a cubic boron nitride coating with a biomimetic structure, and the selection of the substrate is a conventional choice in the field, specifically high-speed steel, hard a...

Embodiment 1

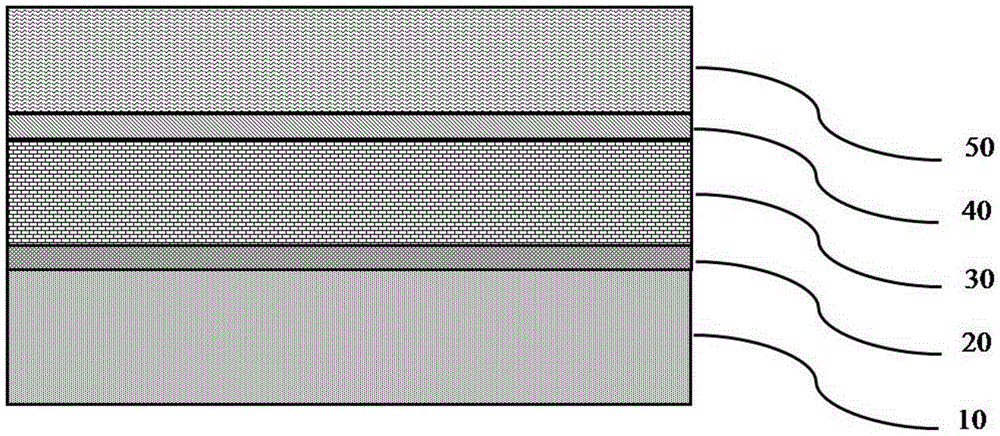

[0043] to combine figure 1 , in the cubic boron nitride coating with biomimetic structure, Cr is used as transition layer 20, WB 2 : Cr / Cr is the multi-layer composite layer 30, W-B-N is the middle layer 40, and the cBN coating is the top coating 50. Taking the YG8 cemented carbide blade as an example, the following steps are adopted.

[0044] S111. Pre-treatment: First, sandblast the YG8 cemented carbide blade to remove surface scale and burrs; then spray the sample with water to remove the residue on the blade surface after sandblasting; then put the blade into Ultrasonic alkali cleaning for degreasing, the treatment time is 5-20min; then the blade is rinsed with clear water circulation, the time is 10-20min; after that, the sample is put into deionized water for ultrasonic cleaning for 10-20min, and then the surface is blown with dry nitrogen Dry, and then put the sample in a vacuum drying oven to dry; and clamp the dried sample on the turntable of the magnetron sputtering...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com