A kind of preparation method of p-type SNO2 film

A thin film and powder technology, which is applied in the field of preparation of p-type SnO2 thin films, can solve the problems of high electron carrier concentration, low concentration, poor electrical properties of p-type transparent conductive thin films, etc., to increase the hole carrier concentration, The effect of simple coating technology and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Pretreatment of soda-lime glass substrate. In the experiment, the soda-lime glass substrate should be pretreated first. First, cut the soda-lime glass into the required size with a glass knife, and then calcinate it at 500°C for 3 hours, then clean it with detergent, and then rinse it with deionized water. Then place it in an ultrasonic cleaner and clean it with acetone, absolute ethanol, and deionized water for 15 minutes, and finally dry it with high-purity nitrogen to obtain a substrate with a clean surface required for the experiment.

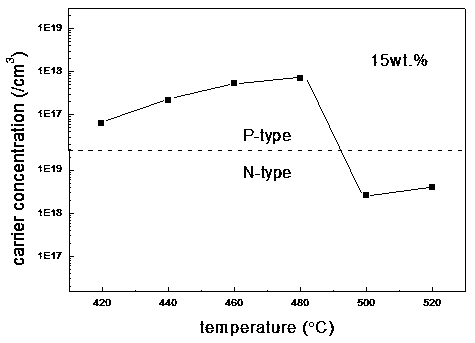

[0032] (2) Target preparation. GaN with a total weight of 4 g and a purity of 99.999% and SnO with a purity of 99.999% 2 The powder is weighed according to a certain ratio, wherein the GaN powder mass ratio is 15wt.%. Then fully grind the weighed powder with a ball mill, wherein the ball milling time is four hours, and the speed is 2000 rpm; then the powder after the uniform mixing is pressed into tablets, the pressure is cont...

Embodiment 2

[0039] (1) Soda-lime glass pretreatment. With embodiment 1.

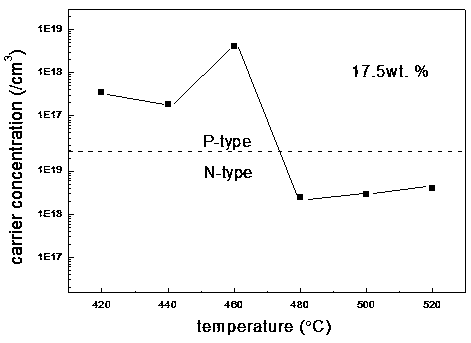

[0040] (2) Target preparation. GaN with a total weight of 4 g and a purity of 99.999% and SnO with a purity of 99.999% 2 The powder is weighed according to a certain ratio, wherein the mass ratio of GaN powder is 17.5wt.%. Then fully grind the weighed powder with a ball mill, wherein the ball milling time is four hours, and the speed is 2000 rpm; then the powder after the uniform mixing is pressed into tablets, the pressure is controlled at 13MPa, and the pressure is kept for 5 minutes. The specification is 12mm*4mm (diameter*thickness).

[0041] (3) Electron beam evaporation. With embodiment 1.

[0042] (4) Annealing treatment of soda-lime glass coated with film. With embodiment 1.

[0043] (5) TEST. With embodiment 1.

[0044] The test data is as follows:

[0045]

Embodiment 3

[0047] (1) Soda-lime glass pretreatment. With embodiment 1.

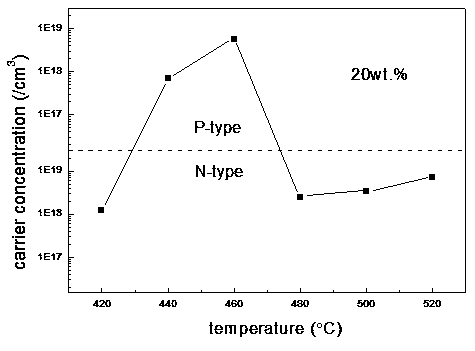

[0048] (2) Target preparation. GaN with a total weight of 4 g and a purity of 99.999% and SnO with a purity of 99.999% 2 The powder is weighed according to a certain ratio, wherein the GaN powder mass ratio is 20wt.%. Then fully grind the weighed powder with a ball mill, wherein the ball milling time is four hours, and the speed is 2000 rpm; then the powder after the uniform mixing is pressed into tablets, the pressure is controlled at 13MPa, and the pressure is kept for 5 minutes. The specification is 12mm*4mm (diameter*thickness).

[0049] (3) Electron beam evaporation. With embodiment 1.

[0050] (4) Annealing treatment of soda-lime glass coated with film. With embodiment 1.

[0051] (5) TEST. With embodiment 1.

[0052] The test data is as follows:

[0053]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com