Interface modifying method of lithium metal battery anode

A lithium metal battery, lithium metal technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of dead lithium, dendrite formation, etc., and achieve the effect of easy operation, easy operation, and good cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1. Preparation of Heterogeneous Copper-Modified Lithium Electrode by Liquid Phase Chemical Replacement Method

[0030] In an inert atmosphere, dissolve anhydrous copper chloride in a propylene carbonate solvent to prepare a 0.05 mol / L reaction solution. At room temperature (25 degrees Celsius), immerse the lithium sheet in the reaction solution and let it stand for 30 minutes. Minutes, after the reaction is complete, take out the lithium sheet, remove the residual reaction solution adsorbed on the surface, wash 3 times with dimethyl carbonate, and vacuum dry to obtain a lithium metal electrode with a conductive metal copper film on the surface.

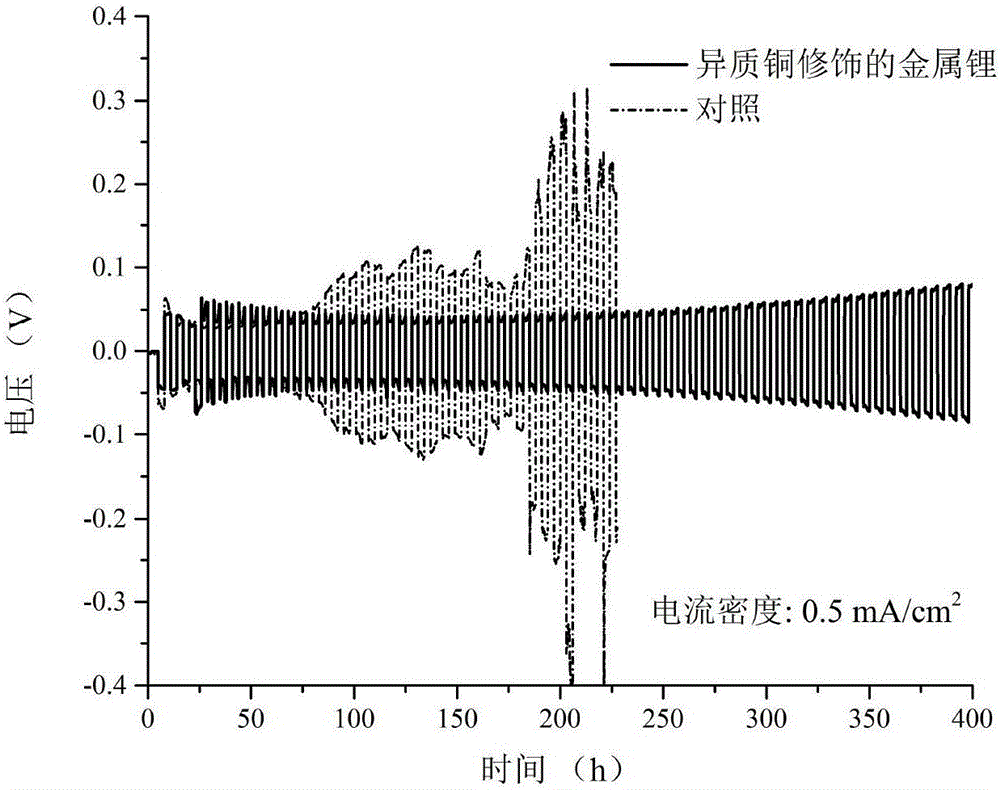

[0031] The performance of the modified lithium electrode can be characterized by a Li|Li symmetric battery, and the electrolyte is 1M LiPF 6 EC-DEC, the diaphragm is Celgard 2400, at a constant current of 0.5 mA / cm 2 Charge and discharge, each charge and discharge process lasts for 3h, such as figure 1 As shown, the v...

Embodiment 2

[0032] Example 2: Preparation of heterogeneous antimony-modified lithium electrodes by liquid-phase chemical displacement method

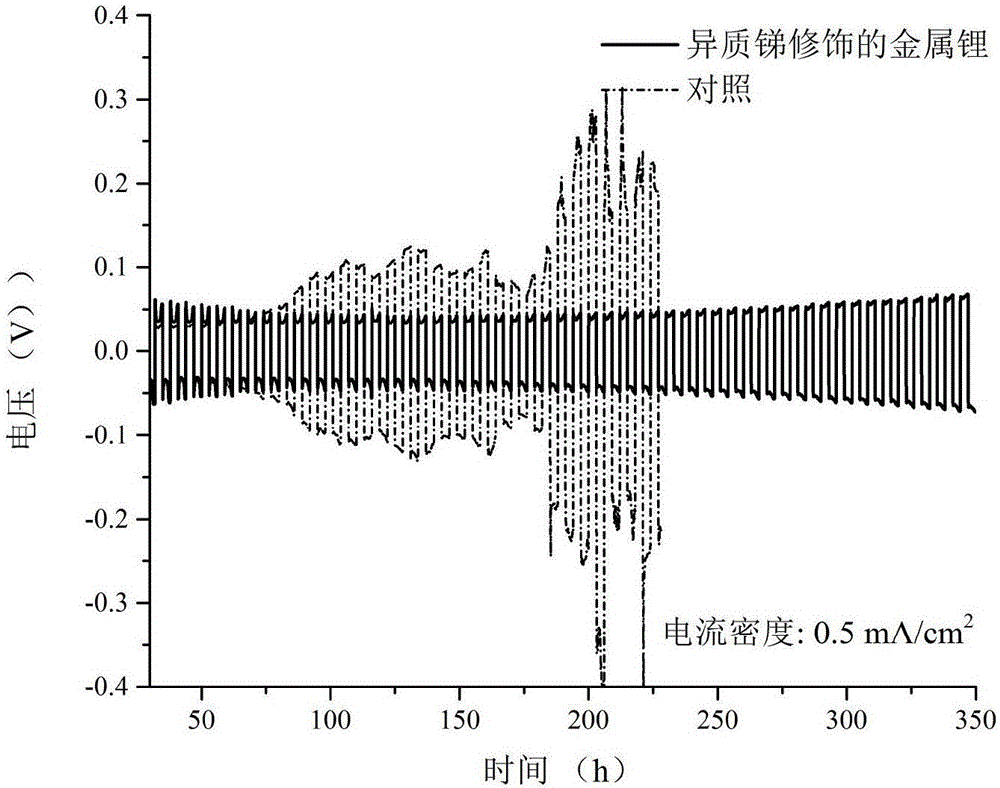

[0033] In an inert atmosphere, anhydrous antimony chloride was dissolved in acetonitrile solvent to prepare a reaction solution of 0.01 moles per liter. According to the method in Example 1, a heterogeneous antimony-modified lithium electrode was prepared and assembled as Li|Li Symmetrical battery, the battery performance test information such as image 3 As shown, the modified lithium electrode obviously exhibits less voltage polarization and long-term cycle stability, and the voltage polarization is still stable at ±48mV after 350h cycle.

Embodiment 3

[0034]Example 3: Heterogeneous zinc-modified lithium metal electrode prepared by liquid-phase chemical displacement method

[0035] In an inert atmosphere, anhydrous zinc chloride was dissolved in propylene carbonate solvent to prepare a 0.05 mol / L reaction solution. According to the method in Example 1, a heterogeneous zinc-modified lithium electrode was prepared and assembled as Li |Li symmetric cells, exhibiting small voltage polarization (±30 mV) and excellent long-term cycling stability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com