a cofe 2 o 4 Preparation method of air cathode catalytic material for /ac microbial fuel cell

A technology of fuel cells and air cathodes, applied in biochemical fuel cells, battery electrodes, nanotechnology for materials and surface science, etc., can solve problems such as high costs, and achieve the effects of cost reduction, low price, and abundant raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The outstanding features of the present invention will be further elaborated below in conjunction with specific examples.

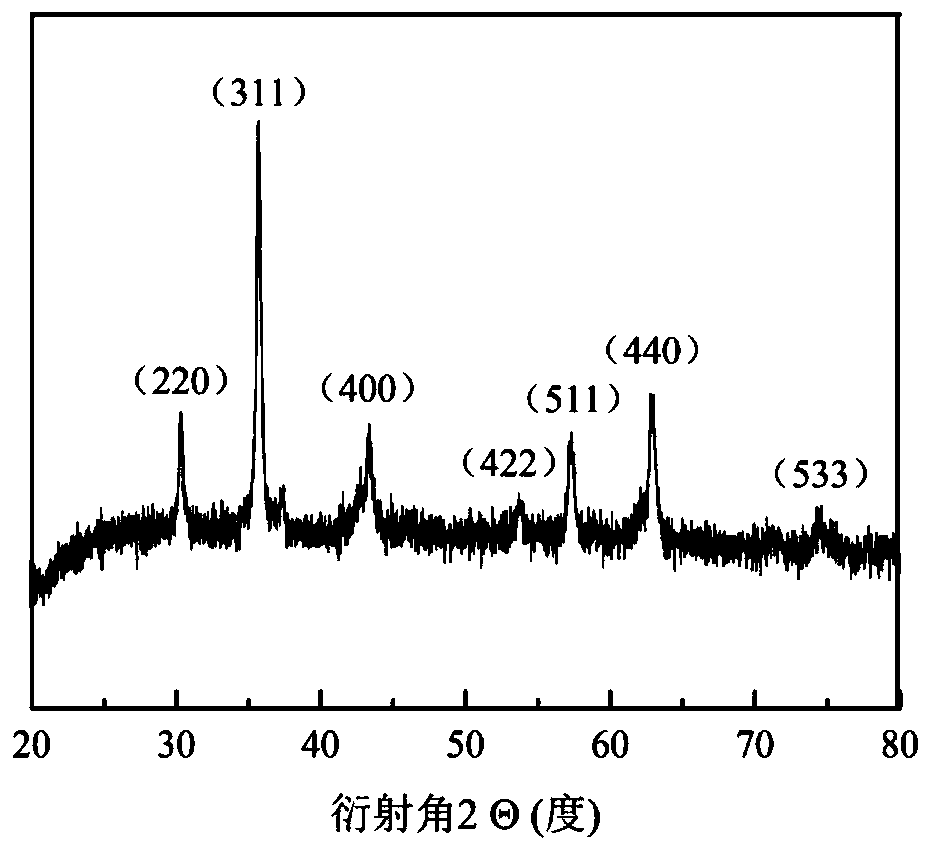

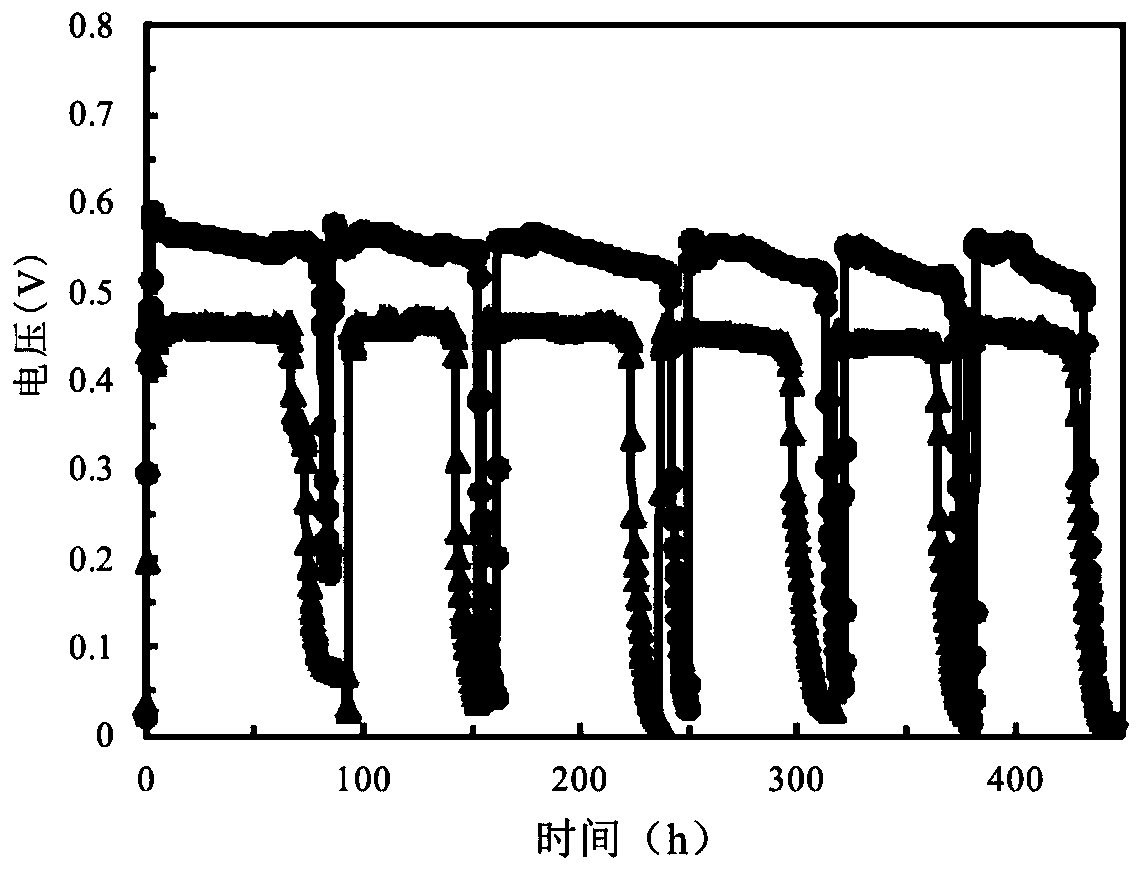

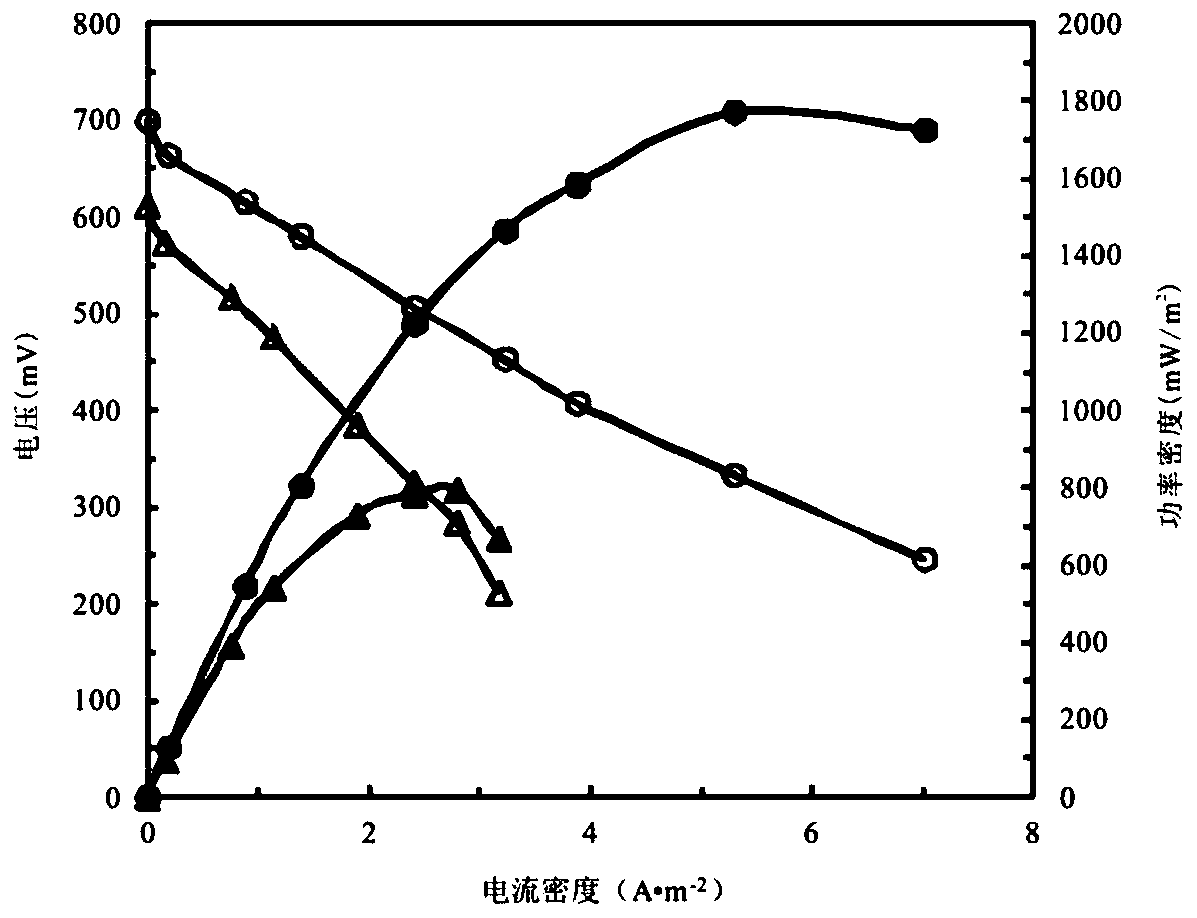

[0025] a CoFe 2 o 4 / AC microbial fuel cell air cathode composite catalytic material, which consists of: cobalt source (CoCl 2 ·6H 2 O, Sinopharm Chemical Reagent Co., Ltd.), iron source (FeCl 3 ·6H 2 O, Sinopharm Chemical Reagent Co., Ltd.), activated carbon (AC, 2100m 2 g -1 , Fuzhou Yihuan Carbon Co., Ltd.), ethylene glycol (EG, Sinopharm Chemical Reagent Co., Ltd.), ammonia (NH 3 ·H 2 O, Sinopharm Chemical Reagent Co., Ltd.), and the rest were deionized.

[0026] Described iron-cobalt solution and CoFe 2 o 4 In / AC, the molar mass ratio of iron (Fe) to cobalt (Co) is 2:1; in the mixed solution of deionized water (DI) and ethylene glycol (EG), the volume ratio of DI to EG is 2:1; The source of iron is ferric chloride (FeCl 3 ·6H 2 O), the cobalt source is cobalt chloride (CoCl 2 ·6H 2 O).

[0027] a CoFe 2 o 4 The preparation m...

Embodiment 2

[0036] a CoFe 2 o 4 / AC microbial fuel cell air cathode catalytic composite material, which consists of: cobalt source (CoCl 2 ·6H 2 O, Sinopharm Chemical Reagent Co., Ltd.), iron source (FeCl 3 ·6H 2 O, Sinopharm Chemical Reagent Co., Ltd.), activated carbon (AC, 2100m 2 g -1 , Fuzhou Yihuan Carbon Co., Ltd.), ethylene glycol (EG, Sinopharm Chemical Reagent Co., Ltd.), ammonia (NH 3 ·H 2 O, Sinopharm Chemical Reagent Co., Ltd.), and the rest were deionized.

[0037] Described iron-cobalt solution and CoFe 2 o 4 In / AC, the molar mass ratio of iron (Fe) to cobalt (Co) is 2:1; in the mixed solution of deionized water (DI) and ethylene glycol (EG), the volume ratio of DI to EG is 2:1; The source of iron is ferric chloride (FeCl 3 ·6H 2 O), the cobalt source is cobalt chloride (CoCl 2 ·6H 2 O).

[0038] a CoFe 2 o 4 The preparation method of / AC microbial fuel cell air cathode catalytic composite material, its steps are:

[0039] 1. Preparation of iron-cobalt sol...

Embodiment 3

[0044] a CoFe 2 o 4 / AC microbial fuel cell air cathode catalytic composite material, which consists of: cobalt source (CoCl 2 ·6H 2 O, Sinopharm Chemical Reagent Co., Ltd.), iron source (FeCl 3 ·6H 2 O, Sinopharm Chemical Reagent Co., Ltd.), activated carbon (AC, 2100m 2 g -1 , Fuzhou Yihuan Carbon Co., Ltd.), ethylene glycol (EG, Sinopharm Chemical Reagent Co., Ltd.), ammonia (NH 3 ·H 2 O, Sinopharm Chemical Reagent Co., Ltd.), and the rest were deionized.

[0045] Described iron-cobalt solution and CoFe 2 o 4 In / AC, the molar mass ratio of iron (Fe) to cobalt (Co) is 2:1; in the mixed solution of deionized water (DI) and ethylene glycol (EG), the volume ratio of DI to EG is 2:1; The source of iron is ferric chloride (FeCl 3 ·6H 2 O), the cobalt source is cobalt chloride (CoCl 2 ·6H 2 O).

[0046] a CoFe 2 o 4 / AC microbial fuel cell air cathode catalytic composite material preparation method, the steps are:

[0047] 1. Preparation of iron-cobalt solution:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com