Long-circulation non-aqueous electrolyte battery and preparation method therefor

A non-aqueous electrolyte and long-cycle technology, which is applied in secondary batteries, circuits, electrical components, etc., can solve the problems of complex equipment and cumbersome procedures, and achieve the goals of improving high-temperature cycle life, wide application prospects, and excellent high-temperature cycle performance of batteries Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

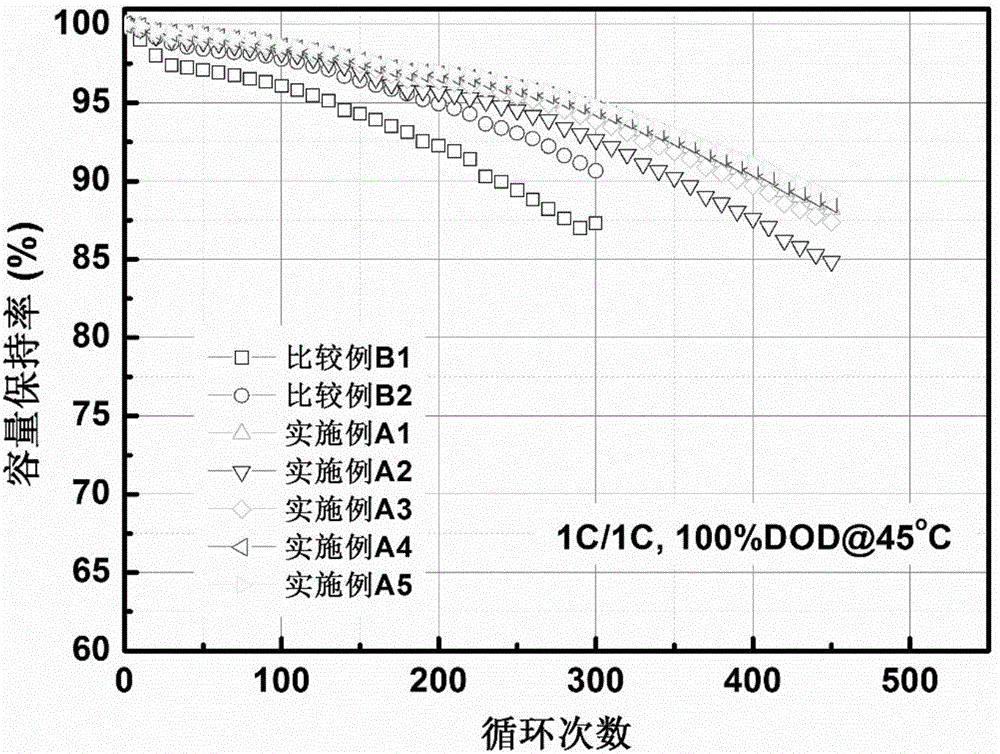

Embodiment 1

[0037] (1) Positive sheet production: nickel-cobalt lithium manganese oxide (LiNi 0.5 co 0.2 mn 0.3 o 2 ): carbon conductive agent: polyvinylidene fluoride powder (PVDF) is mixed, dispersed in N-methylpyrrolidone (NMP) to make positive electrode slurry, the above positive electrode slurry is coated on both sides of 20 μm metal aluminum foil, and dried , rolling, and cutting processes to prepare the positive electrode sheet.

[0038] (2) Negative electrode sheet production: Mix graphite: acetylene black: PVDF in a weight ratio of 95:1:4, disperse in NMP solvent to make negative electrode slurry, and coat the above negative electrode slurry on 10 μm metal copper foil The negative electrode sheet is obtained by drying, rolling, and cutting processes on both sides.

[0039] (3) Preparation of non-aqueous electrolyte: mix ethylene carbonate (EC) and ethyl methyl carbonate (EMC) in a ratio of 1:2 by volume, and in the mixed solvent, control the concentration of lithium hexafluor...

Embodiment 2

[0045] Compared with Example 1, the only difference is that the shape memory polymer material is styrene-butadiene copolymer, and its heat distortion temperature is 60°C.

[0046] The rest are the same as in Embodiment 1, and will not be repeated here. Hereinafter, the battery thus produced is referred to as battery A2.

Embodiment 3

[0048] Compared with Example 1, the only difference is: the separator substrate uses a microporous polypropylene film with a thickness of 20 μm, the functional coating uses styrene-butadiene rubber with a thickness of 2 μm, and the separator has a porosity of 40%.

[0049] The rest are the same as in Embodiment 1, and will not be repeated here. Hereinafter, the battery thus produced is referred to as battery A3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com