Antibacterial wear-resisting plastic

A plastic and modified technology, applied in the field of antibacterial and wear-resistant plastics, can solve the problems of unstable plastic quality, poor wear resistance, and reduced service life, and achieve easy aging, good aging resistance, and improved compatibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

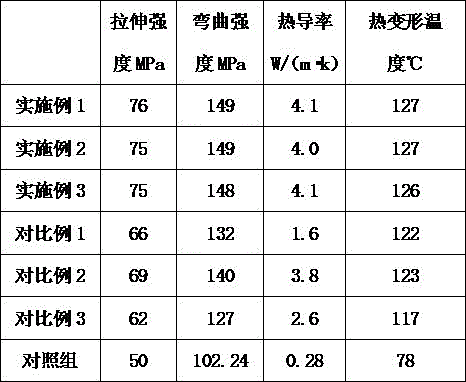

Examples

Embodiment 1

[0020] An antibacterial and wear-resistant plastic, made of the following components in parts by weight: modified polyvinyl chloride 64, polycaprolactone 16, silicon micropowder 3, polypropylene resin 14, potassium humate 0.4, propylene glycol methyl ether acetate 3 , bamboo fiber 2, zinc borate 0.2, potassium titanate whisker 1.4, silane coupling agent 0.3, epoxy soybean oil 0.8, modified halloysite 8.

Embodiment 2

[0022] An antibacterial and wear-resistant plastic, made of the following components in parts by weight: modified polyvinyl chloride 68, polycaprolactone 20, silicon micropowder 6, polypropylene resin 16, potassium humate 0.8, propylene glycol methyl ether acetate 7 , bamboo fiber 5, zinc borate 0.4, potassium titanate whisker 1.6, silane coupling agent 0.7, epoxy soybean oil 1.2, modified halloysite 12.

Embodiment 3

[0024] An antibacterial and wear-resistant plastic, made of the following components in parts by weight: modified polyvinyl chloride 66, polycaprolactone 18, silicon micropowder 5, polypropylene resin 15, potassium humate 0.6, propylene glycol methyl ether acetate 4 , bamboo fiber 3, zinc borate 0.3, potassium titanate whisker 1.5, silane coupling agent 0.4, epoxy soybean oil 1.0, modified halloysite 10.

[0025] In the above example:

[0026] The preparation method of the modified polyvinyl chloride is as follows: heat the polyvinyl chloride to 98°C, then add 4% of the mass of the mixed ethanol extract of rice grass and cucurbit tea, stir at a speed of 450r / min for 26min, and then add polyvinyl chloride Aluminum powder with 1.5% ethylene mass is stirred evenly, then stirred at 720r / min for 40min in a corona field with a relative air humidity of 35% and a field strength of 200kv / m, and then left to stand.

[0027] The preparation method of the mixed ethanol extract of rice ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com