Nanofiber cellulose-based hydrogel loaded metal catalyst for degrading trichlorophenol in water body and preparation method of catalyst

A technology of nano-cellulose and metal catalysts, applied in alkali metal compounds, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of unsatisfactory recycling effects, secondary pollution of nanoparticles, and weak binding of silver particles To achieve good biodegradability, broaden the concentration range, and avoid poor reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

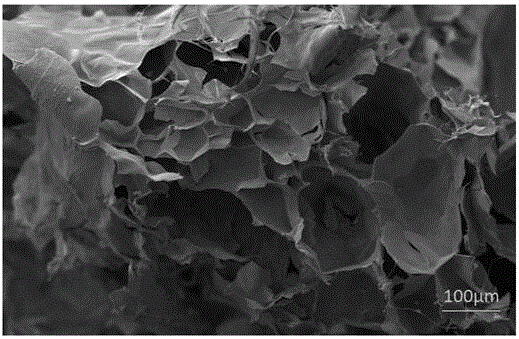

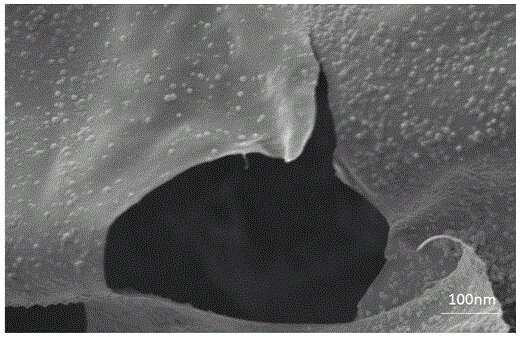

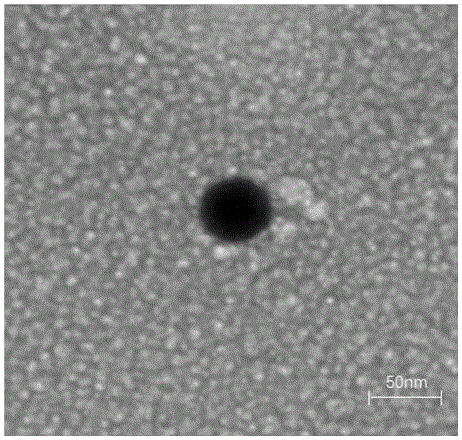

Method used

Image

Examples

Embodiment 1

[0037] (1) First put the nanocellulose solution in an Erlenmeyer flask, put it into a 50°C rotary evaporator to evaporate, remove the excess water contained therein, and obtain a nanocellulose suspension with a solid content of 2%. Take 8.5g of nanocellulose suspension and place it in a three-necked flask, then add 13.0g of polyvinyl alcohol solution with a concentration of 10wt%, and 13g of carboxymethylcellulose solution with a concentration of 2wt%, stir mechanically, and heat in a water bath at 60°C React for 55 minutes.

[0038] (2) Add 0.4 ml of glacial acetic acid to the mixed solution obtained in step (1), and then add 2 ml of a cross-linking agent glutaraldehyde solution with a mass concentration of 25% dropwise after 15 minutes. Add once, the interval between two times is 5min, and react for 0.5 hour after the dropwise addition is completed;

[0039] (3) After the reaction is completed, the vacuum treatment is carried out immediately. When a certain degree of vacuum...

Embodiment 2

[0046] (1) First put the nanocellulose solution in an Erlenmeyer flask, put it into a 50°C rotary evaporator to evaporate, remove the excess water contained therein, and obtain a nanocellulose suspension with a solid content of 3%. Take 14.1g of nanocellulose suspension and place it in a three-necked flask, then add 13.0g of polyvinyl alcohol solution with a concentration of 10wt%, and 19.5g of carboxymethylcellulose solution with a concentration of 2wt%, stir mechanically, and place in a water bath at 45°C The reaction was heated for 75 minutes.

[0047] (2) Add 0.7ml of glacial acetic acid to the mixed solution obtained in step (1), and then add 3ml of a cross-linking agent glutaraldehyde solution with a mass concentration of 25% dropwise after 15 minutes. Add once, the interval between two times is 5min, and react for 1.5 hours after the dropwise addition is completed;

[0048] (3) After the reaction is completed, the vacuum treatment is carried out immediately. When a cer...

Embodiment 3

[0055] (1) First put the nanocellulose solution in an Erlenmeyer flask, put it into a 50°C rotary evaporator to evaporate, remove the excess water contained therein, and obtain a nanocellulose suspension with a solid content of 4%. Take 18.1g of nanocellulose suspension and place it in a three-necked flask, then add 13.0g of polyvinyl alcohol solution with a concentration of 10wt%, and 26g of carboxymethylcellulose solution with a concentration of 2wt%, stir mechanically, and heat in a water bath at 75°C React for 30 minutes.

[0056] (2) Add 1ml of glacial acetic acid to the mixed solution obtained in step (1), and then add 4ml of a cross-linking agent glutaraldehyde solution with a mass concentration of 25% dropwise after 15 minutes. Add, the interval between two times is 5min, and react for 2 hours after the dropwise addition is completed;

[0057] (3) After the reaction is completed, the vacuum treatment is carried out immediately. When a certain degree of vacuum is drawn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com