A kind of preparation method of mulberry microbial compound preparation with hypoglycemic and laxative functions

A compound preparation, microbial technology, applied in the functions of food ingredients, bacteria used in food preparation, food science and other directions, can solve the problems of restricting the wide application of diabetic food, not found, etc., to achieve the treatment of digestive disorders, avoid changes, The effect of hypoglycemic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

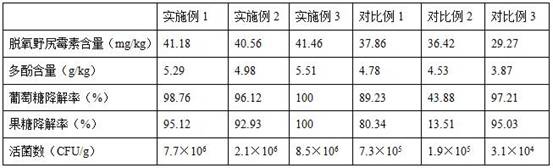

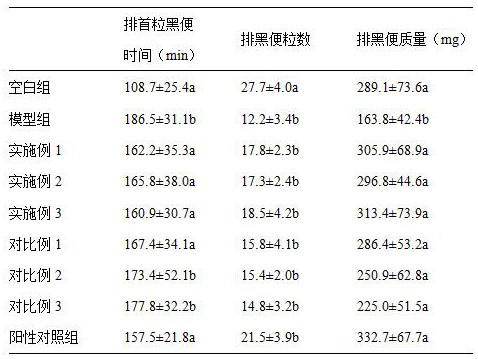

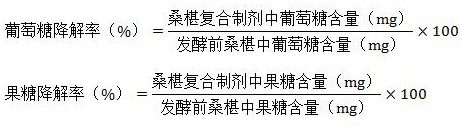

Examples

Embodiment 1

[0035] A kind of preparation method of the mulberry microorganism composite preparation with hypoglycemic and catharsis function, comprises the following steps:

[0036] a) Take fresh mulberries and carry out colloid mill wet ultrafine pulverization. The process of colloid mill wet ultrafine pulverization is as follows: colloid mill gap size is 15 μm, grinding 4 times, unit processing capacity 4000g / min, at a temperature of 121°C , after high-pressure steam sterilization for 30 minutes, the whole pulp of mulberry fruit was obtained;

[0037] b) Inoculate the whole pulp of mulberries with Leuconostoc enterococci Leuconostoc mesenteroides At an inoculum size of 4 x 10 6 CFU / mL, fermentation temperature 30°C, fermentation pH 6.0, fermented for 84h, and the number of viable probiotic bacteria was 8.2×10 7 CFU / mL of mulberry fermentation stock solution;

[0038] c) Inoculate the obtained mulberry fermentation liquid into Saccharomyces cerevisiae Saccharomyces cerevisiae , both...

Embodiment 2

[0041] A kind of preparation method of the mulberry microorganism composite preparation with hypoglycemic and catharsis function, comprises the following steps:

[0042] a) Take fresh mulberries and carry out colloid mill wet ultrafine pulverization. The process of colloid mill wet ultrafine pulverization is as follows: colloid mill gap size is 5 μm, grinding 5 times, unit processing capacity 5000g / min, at a temperature of 121°C , after high-pressure steam sterilization for 30 minutes, the whole pulp of mulberry fruit was obtained;

[0043] b) Inoculate the whole pulp of mulberries with Leuconostoc enterococci Leuconostoc mesenteroides At an inoculum size of 2 x 10 6 CFU / mL, fermentation temperature 35°C, fermentation pH 6.5 for 72 hours, the number of viable probiotic bacteria was 1.5×10 7 CFU / mL of mulberry fermentation stock solution;

[0044] c) Inoculate the obtained mulberry fermentation liquid into Saccharomyces cerevisiae Saccharomyces cerevisiae , both yeast and Le...

Embodiment 3

[0047] A kind of preparation method of the mulberry microorganism composite preparation with hypoglycemic and catharsis function, comprises the following steps:

[0048] a) Take fresh mulberries and carry out colloid mill wet ultrafine pulverization. The process of colloid mill wet ultrafine pulverization is as follows: colloid mill gap size is 25 μm, grinding twice, unit processing capacity 3000g / min, at a temperature of 121°C , after high-pressure steam sterilization for 30 minutes, the whole pulp of mulberry fruit was obtained;

[0049] b) Inoculate the whole pulp of mulberries with Leuconostoc enterococci Leuconostoc mesenteroides At an inoculum size of 5 x 10 6 CFU / mL, fermentation temperature 25°C, fermentation pH 5.5, fermented for 96h, and the number of viable probiotic bacteria was 10 8 CFU / mL of mulberry fermentation stock solution;

[0050] c) Inoculate the obtained mulberry fermentation liquid into Saccharomyces cerevisiae Saccharomyces cerevisiae , both yeast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com