High-frequency and high-speed flexible copper-clad plate and preparation method thereof

A flexible copper-clad laminate, high-speed technology, applied in chemical instruments and methods, other household appliances, electronic equipment, etc., can solve the problems of vacuum system corrosion failure, tensile strength decrease, elongation decrease, etc. The method is simple and efficient Effective, wettability improvement, adhesion improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

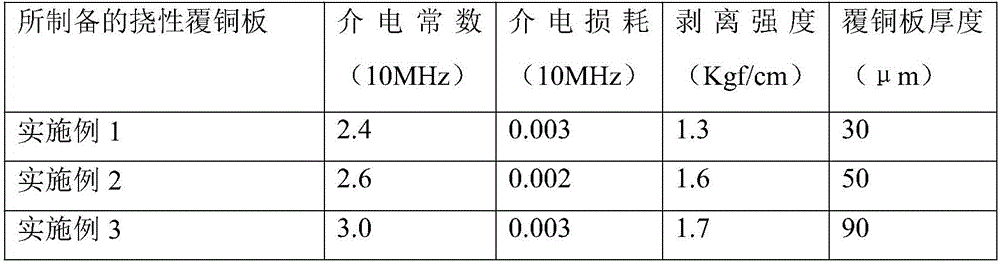

Embodiment 1

[0013] Weigh the refined naphthalene of 100kg and the tetrahydrofuran of 600kg, stand-by. Feed nitrogen into the self-made reaction kettle, add the prepared tetrahydrofuran after stabilization, then open the stirrer and start stirring, add 100kg of refined naphthalene simultaneously, and make the naphthalene completely dissolved by stirring. Then turn on the cooling device, and gradually add 10kg of sodium metal into small pieces. After adding all the sodium metal, control the temperature and react at 10°C for 2 hours. After the reaction was completed, the stirring was stopped, and the temperature was slowly returned to normal temperature, and the material was discharged. Spray the above-mentioned PTFE surface treatment solution evenly on the surface of the PTFE film, the surface treatment time is about 10s, then pull the film, soak it in a washing tank filled with acetone for 1min, rinse it with clean water, and then carry out dry. Then, the epoxy resin adhesive is evenly c...

Embodiment 2

[0015] Weigh the refined naphthalene of 100kg and the tetrahydrofuran of 800kg, stand-by. Feed nitrogen into the self-made reaction kettle, add the prepared tetrahydrofuran after stabilization, then open the stirrer and start stirring, add 100kg of refined naphthalene simultaneously, and make the naphthalene completely dissolved by stirring. Then turn on the cooling device, and gradually add 15kg of sodium metal into small pieces. After adding all the sodium metal, control the temperature and react at 15°C for 1 hour. After the reaction was completed, the stirring was stopped, and the temperature was slowly returned to normal temperature, and the material was discharged. Spray the above-mentioned PTFE surface treatment solution evenly on the surface of the PTFE film, the surface treatment time is about 15s, then pull the film, soak it in the washing tank with ethanol for 2 minutes, rinse it with clean water, and then carry out dry. Then, the acrylate adhesive is evenly coate...

Embodiment 3

[0017] Weigh the refined naphthalene of 100kg and the tetrahydrofuran of 650kg, stand-by. Feed nitrogen into the reaction kettle, add the prepared tetrahydrofuran after stabilization, then open the stirrer and start stirring, add 100kg of refined naphthalene simultaneously, and make the naphthalene completely dissolved by stirring. Then turn on the cooling device, and gradually add 13kg of sodium metal into small pieces. After adding all the sodium metal, control the temperature and react at 10°C for 2 hours. After the reaction was completed, the stirring was stopped, and the temperature was slowly returned to normal temperature, and the material was discharged. Spray the above-mentioned PTFE surface treatment liquid evenly on the surface of PTFE film, the surface treatment time is about 10s, then pull the film, soak it in a washing tank filled with methanol for 2 minutes, rinse it with clean water, and then carry out dry. Then, evenly coat the silicone adhesive on the surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com