Method and product for recovering and reusing diamond

A diamond and sapphire technology, which is applied in the field of diamond recycling and reuse, can solve the problems of waste, diamond particles cannot be recycled, etc., and achieve the effect of simple process, eliminating hidden dangers of combustion, and high particle purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

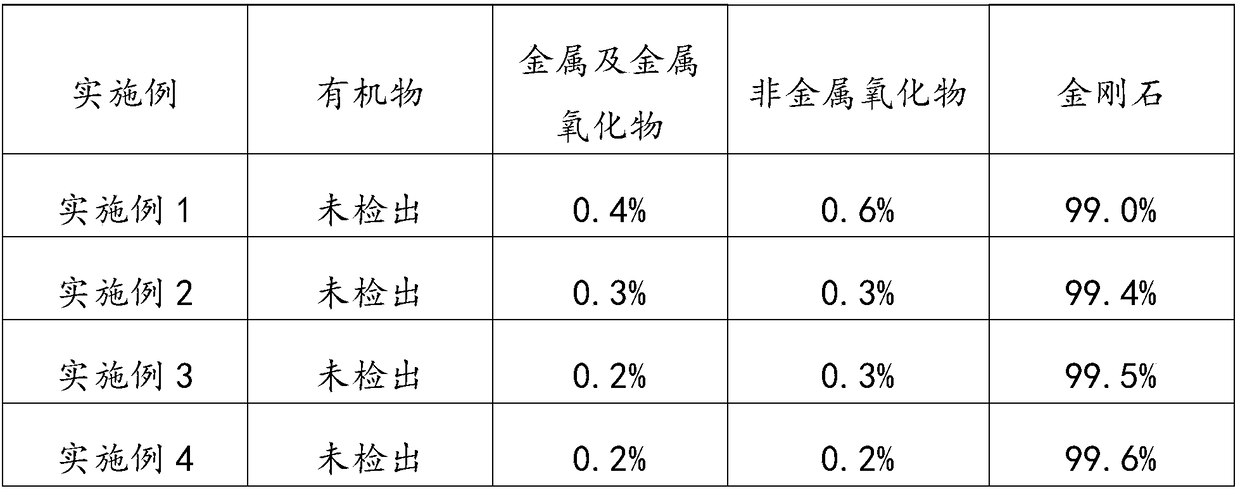

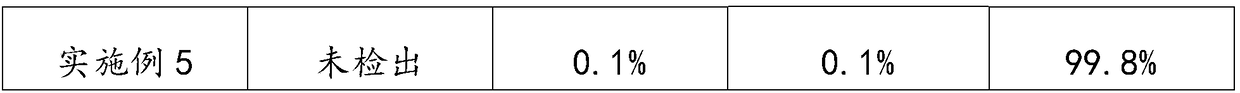

Examples

Embodiment 1

[0085] A method for reclaiming diamond from sapphire grinding waste slurry, comprising the steps of:

[0086] (1) Use a three-legged centrifuge to centrifugally deoil the collected grinding waste to obtain a centrifugal bottom material; the resulting centrifugal bottom material contains polycrystalline diamond, copper powder, phenolic resin, aluminum oxide, organic solvents, etc.;

[0087] (2) The centrifuge base material obtained in step (1) is vacuum-dried in a vacuum drying oven, the drying temperature is 100°C, the vacuum degree is -0.005MPa, and the drying time is 8h;

[0088](3) pulverize the dried material obtained in step (2) using a pulverizer; the pulverized material contains polycrystalline diamond, copper powder, phenolic resin, aluminum oxide, etc.;

[0089] (4) Put the pulverized material of step (3) into the quartz reactor, add the sulfuric acid solution with a concentration of 75wt%, the mass ratio of the material to the sulfuric acid solution is 1:30, and the ...

Embodiment 2

[0099] A method for reclaiming diamond from sapphire grinding waste slurry, comprising the steps of:

[0100] (1) Use a three-legged centrifuge to centrifugally deoil the collected grinding waste to obtain a centrifugal bottom material; the resulting centrifugal bottom material contains polycrystalline diamond, copper powder, phenolic resin, aluminum oxide, organic solvents, etc.;

[0101] (2) The centrifuge base material obtained in step (1) is vacuum-dried in a vacuum drying oven, the drying temperature is 500°C, the vacuum degree is -0.08MPa, and the drying time is 2h;

[0102] (3) pulverize the dried material obtained in step (2) using a pulverizer; the pulverized material contains polycrystalline diamond, copper powder, phenolic resin, aluminum oxide, etc.;

[0103] (4) Put the pulverized material of step (3) into the quartz reactor, add the sulfuric acid solution with a concentration of 90wt%, the mass ratio of the material to the sulfuric acid solution is 2:30, and the ...

Embodiment 3

[0113] A method for reclaiming diamond from sapphire grinding waste slurry, comprising the steps of:

[0114] (1) Use a three-legged centrifuge to centrifugally deoil the collected grinding waste to obtain a centrifugal bottom material; the resulting centrifugal bottom material contains polycrystalline diamond, copper powder, phenolic resin, aluminum oxide, organic solvents, etc.;

[0115] (2) The centrifuge base material obtained in step (1) is vacuum-dried in a vacuum drying oven, the drying temperature is 200°C, more preferably 240°C, the vacuum degree is -0.1MPa, and the drying time is 4h;

[0116] (3) pulverize the dried material obtained in step (2) using a pulverizer; the pulverized material contains polycrystalline diamond, copper powder, phenolic resin, aluminum oxide, etc.;

[0117] (4) Put the pulverized material of step (3) into the quartz reactor, add the sulfuric acid solution with a concentration of 80wt%, the mass ratio of the material to the sulfuric acid solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com