A method and device for electrochemical cathode excitation of permanganate to degrade pollutants in water

A permanganate, cathode excitation technology, applied in electrochemical water/sewage treatment, water pollutants, chemical instruments and methods, etc., can solve problems such as poor heavy metal effect, reduce usage, reduce costs, and improve excitation The effect of activation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

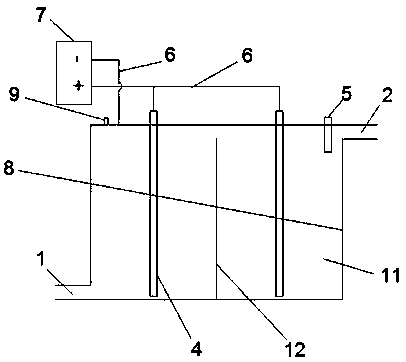

Method used

Image

Examples

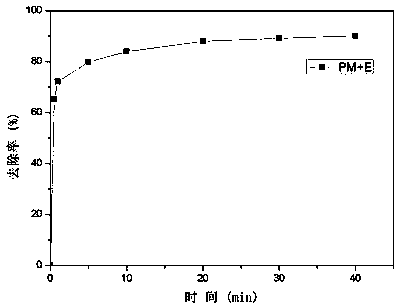

Embodiment 1

[0033] The electrode reactor with the above structure is used to treat sewage containing 20 μM diclofenac sodium. The steps are as follows: inject the sewage to be treated into the reaction chamber, then add electrolyte to make the electrolyte concentration 0.05M, and then add permanganate to make the permanganate The concentration is 20μM, start the DC power supply, keep the permanganate concentration at 20μM and the current of 80mA, after 40min of treatment, the treated sewage is discharged from the outlet.

[0034] In this embodiment, the permanganate is potassium permanganate. When adding, the potassium permanganate is completely dissolved with an appropriate amount of water, and then added into the reaction chamber through the water inlet; the electrolyte is sodium sulfate and potassium carbonate, and the sulfuric acid The mass ratio of sodium to potassium carbonate is 1:0.7; the anode of the electrode reactor is a platinum-plated titanium electrode, and the cathode is a p...

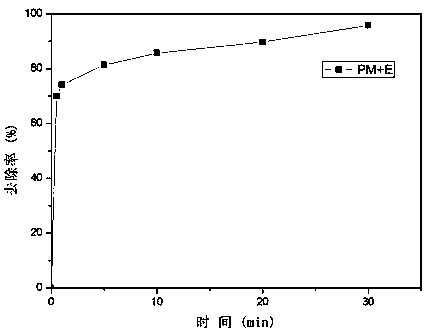

Embodiment 2

[0037] The electrode reactor with the above structure is used to treat sewage containing 20 μM diclofenac sodium. The steps are as follows: inject the sewage to be treated into the reaction chamber, then add electrolyte to make the electrolyte concentration 0.05M, and then add permanganate to make the permanganate The concentration is 100μM, start the DC power supply, keep the concentration of permanganate at 100μM and the energizing current at 200mA, after 30 minutes of treatment, the treated sewage is discharged from the outlet.

[0038] In this embodiment, the permanganate is sodium permanganate. When adding, the sodium permanganate is completely dissolved with an appropriate amount of water, and then added into the reaction chamber through the water inlet; the electrolyte is sodium sulfate and potassium carbonate, and sulfuric acid The mass ratio of sodium to potassium carbonate is 1:0.7; the anode of the electrode reactor is a platinum-plated titanium electrode, and the ca...

Embodiment 3

[0041] The electrode reactor with the above structure is used to treat sewage containing 20 μM diclofenac sodium. The steps are as follows: inject the sewage to be treated into the reaction chamber, then add electrolyte to make the electrolyte concentration 0.05M, and then add permanganate to make the permanganate The concentration is 100μM, start the DC power supply, keep the concentration of permanganate at 100μM and the energizing current at 100mA, after 30 minutes of treatment, the treated sewage is discharged from the outlet.

[0042] In this embodiment, the permanganate is sodium permanganate. When adding it, first dissolve the sodium permanganate completely with an appropriate amount of water, and then add it into the reaction chamber through the water inlet; the electrolyte is sodium sulfate; the anode of the electrode reactor is Platinum-plated titanium electrode, the cathode is a platinum-plated titanium coated electrode.

[0043] Record the concentration change of d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com