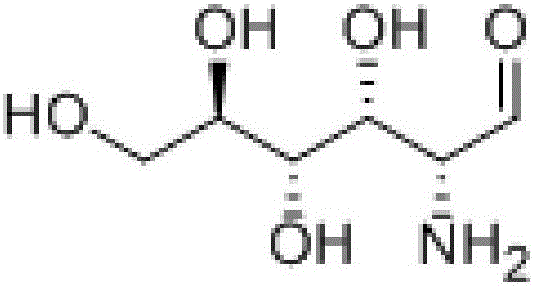

Method for removing acetyl and coupling, adsorbing and separating D-glucosamine hydrochloride

A technology of glucosamine hydrochloride and glucosamine, which is applied in amino sugar, chemical instruments and methods, sugar derivatives, etc., can solve the problems of high energy consumption, large environmental pollution, complicated processes, etc., and achieves high extraction yield, The effect of less environmental pollution and low consumption of auxiliary materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1 The method of deacetylation coupling adsorption separation D-glucosamine hydrochloride

[0026] The specific steps of the method are as follows:

[0027] 1. Heat and inactivate 200L of fermentation broth containing 98g / L of N-acetyl-D-glucosamine, filter it with a ceramic membrane with a pore size of 5nm, and dialyze the dense phase of the membrane with pure water to obtain 80.5g / L of N-acetyl-D-glucosamine. Filtrate 240L;

[0028] 2. Pump 240L ceramic membrane filtrate into the + Type strong acidic cation exchange resin (D001 strong acidic cation exchange resin produced by Jiangsu Suqing Water Treatment Engineering Group Co., Ltd.) deacetylation adsorption separation device, the reaction time of materials in the device is 240 minutes, and the reaction temperature is 90 ° C. Wash the saturated resin with pure water, and analyze the D-glucosamine (H) adsorbed in the resin with 12% hydrochloric acid. + The molar ratio to N-acetyl-D-glucosamine is 1:0.9-10)...

Embodiment 2

[0032] Example 2 The method of deacetylation coupling adsorption separation of D-glucosamine hydrochloride

[0033] The specific steps of the method are as follows:

[0034] 1. Heat and inactivate 200L of fermentation broth containing 95g / L of N-acetyl-D-glucosamine, filter it with a ceramic membrane with a pore size of 50nm, dialyze the dense phase of the membrane with pure water, and obtain a filter with a content of 80g / L. Liquid outlet 235L;

[0035] 2. Add 235L of filtrate to the electrodialysis device, and obtain 320L of desalted solution with a content of 58g / L after desalination by electrodialysis;

[0036] 3. Pump 320L of desalted liquid into the 001×7H filled with Shanghai Huazhen Technology Co., Ltd. + Type strong acid cation exchange resin deacetylation adsorption separation device, the reaction time of materials in the device is 180 minutes, and the reaction temperature is 93 ℃. Wash the saturated resin with pure water, and analyze the D-glucosamine (H) adsorbe...

Embodiment 3

[0040] Example 3 The method of deacetylation coupling adsorption separation of D-glucosamine hydrochloride

[0041] The specific steps of the method are as follows:

[0042] 1. 200L of fermentation broth containing 90g / L of N-acetyl-D-glucosamine after heat inactivation was filtered through a ceramic membrane with a pore size of 50nm, and the dense phase of the membrane was dialyzed with pure water. After merging the filtrates, use an organic roll-type membrane with a molecular weight cut-off of 3000D to filter, and dialyze the dense phase with pure water to obtain 281 L of filtrate with a content of 62 g / L;

[0043] 2. Pass 281L of the filtrate through a decolorization column filled with granular activated carbon and a cation exchange column filled with 001×7 strong acidic cation exchange resin produced by Zibo Dongda Chemical Industry Co., Ltd. to obtain 335L of decolorized and desalted liquid with a content of 51g / L ;

[0044] 3. The 335L decolorization and desalination l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com