A high-pressure-resistant composite material and method for preparing carbon nanotubes modified by atomic layer deposition technology

A technology of atomic layer deposition and carbon nanotubes, which is applied in the field of high-voltage composite material preparation, can solve the problems of reduced dielectric breakdown strength and high dielectric loss of composite materials, and achieve improved dielectric breakdown strength and high dielectric constant. , The effect of increasing the relative permittivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] (1) acidifying carbon nanotubes with a mixed acid solution of sulfuric acid and nitric acid;

[0050] Configure the mixed acid solution according to the volume ratio of nitric acid and sulfuric acid as 1:4, and add carbon nanotubes at a ratio of 200 mg of particles per 20 ml of mixed acid to obtain a carbon nanotube suspension; the obtained carbon nanotube suspension is ultrasonically After oscillating for 30 minutes, place it in a water bath at 70 degrees Celsius and stir it magnetically for 3 hours; dilute the obtained suspension with deionized water, and use a suction filtration device to carry out suction filtration until the hydrogen ion concentration index of the suspension reaches 5; dry and collect, Acidified carbon nanotubes are obtained.

[0051] (2) Place the acidified carbon nanotubes in an atomic layer deposition chamber at 300°C, use nitrogen as the carrier gas, and blow into the trimethylaluminum source in the form of steam for 0.1 second, and then flush ...

Embodiment 2

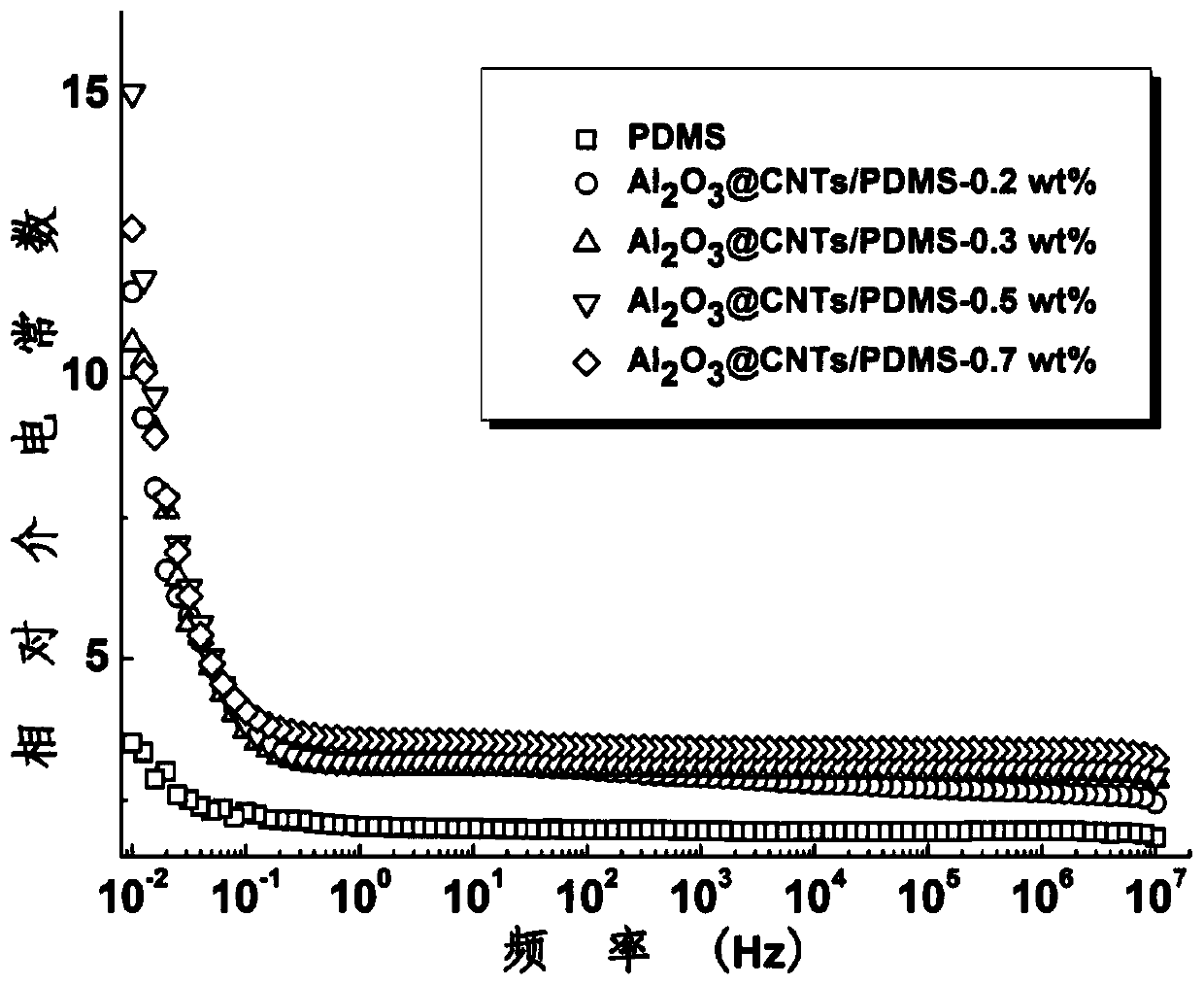

[0069] The quality of the modified carbon nanotubes in step (3) is adjusted to account for 0.2%, 0.5% and 0.7% of the polymer mass respectively, and the other conditions are the same as in Example 1, and the relative dielectric constant of the obtained composite material is verified. .

[0070] image 3 It is the relation curve of relative permittivity and mass fraction of the composite material. The realization results show that for the composite material prepared by ALD deposition of aluminum oxide modified carbon nanotubes, when the mass fraction of doped carbon nanotubes is 0.7wt%, the dielectric constant is at a frequency of 10 7 Hz increased from 2 to 4 of the polymer, an increase of two times; when the doping concentration was 0.5wt%, the dielectric constant was at a frequency of 10 -2 Hz is increased from 3.5 to 15, which is more than 4 times stronger, and the relative permittivity is significantly increased, and with the increase of doping concentration, the relativ...

Embodiment 3

[0072] In step (3), the carbon nanotubes are directly doped, and the doping amounts are 0-1%, and the other conditions are the same as in Example 1, and the breakdown of the obtained composite material is verified.

[0073] Figure 4 Table 3 and Table 3 are the relationship charts between the dielectric breakdown and doping concentration of the composite materials, respectively.

[0074] The dielectric breakdown strength of the composite material that table 3 embodiment 2 makes

[0075] Carbon nanotube doping amount (%)

[0076] The experimental results show that the dielectric breakdown strength of the composite material is significantly reduced by directly doping carbon nanotubes; and for the composite material prepared by doping aluminum oxide modified carbon nanotubes, the experimental results show that with the increase of doping concentration, The dielectric breakdown strength increases obviously at first, even exceeding the breakdown field strength of the pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com