Soil conditioner based on salsola collina biological carbon and preparation method thereof

A technology of soil improver and pigskin, which is applied in the direction of soil conditioning materials, chemical instruments and methods, fertilizer mixtures, etc., can solve the problems of rare soil improver research, achieve low energy consumption, excellent adsorption performance, and improve yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

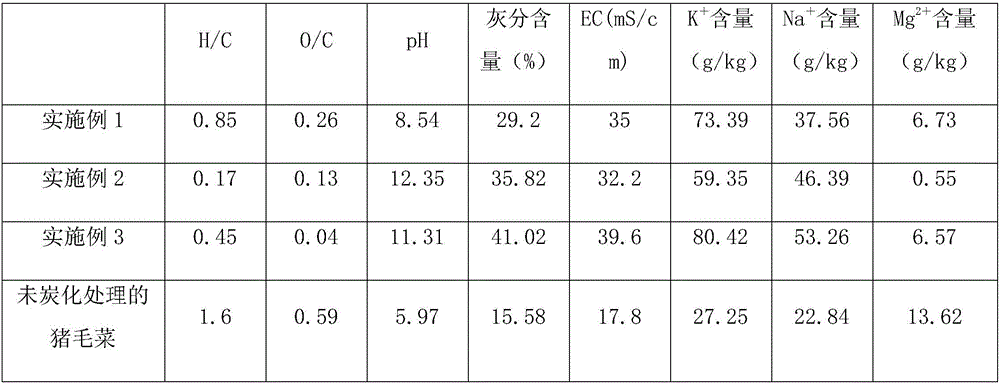

Embodiment 1

[0028] (1) Cut the air-dried pig’s hair into small pieces of 1-2cm, place it in a high-temperature-resistant muffle furnace, and carbonize it at 300°C for 2 hours under anaerobic conditions. After cooling to room temperature, it is crushed and sieved to form Pig vegetable biochar, wherein the particle size of pig vegetable biochar is 1 mm, and the average pore diameter is 4.5 μm.

[0029] (2) In parts by weight, the zeolite pulverized and sieved to form a zeolite powder with a particle diameter of 0.1-1mm, the bentonite pulverized and sieved to form a bentonite powder with a particle diameter of 0.1-0.5mm, 15 parts of zeolite powder, 20 1 part of bentonite powder, 3 parts of amino acid and 0.5 part of citric acid are mixed to form auxiliary materials.

[0030] (3) Add 50 parts of vetch biochar to the above auxiliary materials, add 15 parts of water, and stir to form a granular soil conditioner based on vetch biochar with a particle size of 2 mm.

Embodiment 2

[0032] (1) Cut the air-dried pig’s hair into small pieces of 1-2cm, place it in a high-temperature-resistant muffle furnace, and carbonize it at 700°C for 2 hours under anaerobic conditions. After cooling to room temperature, it is crushed and sieved to form Pig vegetable biochar, wherein the particle size of pig vegetable biochar is 0.1mm, and the average pore diameter is 0.5μm.

[0033] (2) In parts by weight, the zeolite pulverized and sieved to form a zeolite powder with a particle diameter of 0.1-1mm, the bentonite pulverized and sieved to form a bentonite powder with a particle diameter of 0.1-0.5mm, 25 parts of zeolite powder, 30 10 parts of bentonite powder, 10 parts of amino acid and 1.5 parts of citric acid are mixed to form auxiliary materials.

[0034] (3) Add 60 parts of vetch biochar to the above auxiliary materials, add 20 parts of water, and stir to form a granular soil conditioner based on vetch biochar with a particle size of 5 mm.

Embodiment 3

[0036] (1) Cut the air-dried pig’s hair into small pieces of 1-2cm, place it in a high-temperature-resistant muffle furnace, and carbonize it at 500°C for 2 hours under anaerobic conditions. After cooling to room temperature, it is crushed and sieved to form Pig vegetable biochar, wherein the particle size of pig vegetable biochar is 0.5mm, and the average pore diameter is 0.6μm.

[0037] (2) In parts by weight, the zeolite pulverized and sieved to form a zeolite powder with a particle diameter of 0.1-1 mm, the bentonite crushed and sieved to form a bentonite powder with a particle diameter of 0.1-0.5 mm, 20 parts of zeolite powder, 25 1 part of bentonite powder, 5 parts of amino acid and 1 part of citric acid are mixed to form auxiliary materials.

[0038] (3) Add 50 parts of vetch biochar to the above auxiliary materials, add 60 parts of water, and stir to form a solution-like soil conditioner based on slaw biochar with a solid content of 45%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com