High-performance graphene composite para-aramid fiber and preparation method and application thereof

A para-aramid fiber and graphene composite technology, which is applied in the fields of fiber chemical characteristics, spinning solution preparation, wet spinning method, etc., can solve the problem of not endowing excellent performance, single functionality of para-aramid fiber, unsatisfactory, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

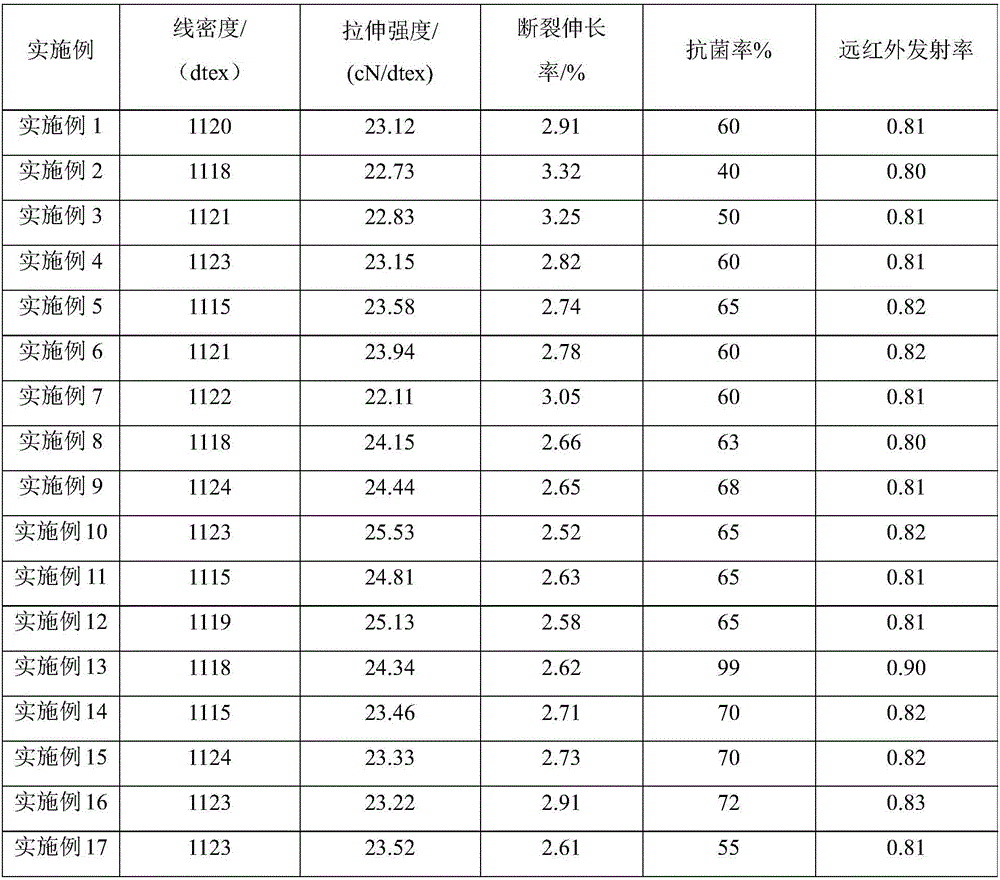

Examples

Embodiment 1

[0051] The preparation method of the high-performance graphene composite para-aramid fiber is as follows:

[0052] 1) Add 8kg of anhydrous calcium chloride, 100kg of N-methylpyrrolidone (NMP), and 3.45kg of p-phenylenediamine (PPD) into the reactor, start stirring, and stir for 30min at room temperature; , let the system temperature drop to 0~-15℃, add the first batch of terephthaloyl chloride (TPC) 1.3kg, continue to stir for 30min, then lower the temperature to 0~-15℃, add the second batch of TPC 5.2kg, stir quickly , after the reaction system appears gel, climbs rods, and is crushed again, the reaction is stopped, and polyparaphenylene terephthalamide (PPTA) is obtained;

[0053] 2) Add 1kg of graphene oxide to 80kg of 95wt% concentrated sulfuric acid, and ultrasonically disperse for 1h to obtain a stable dispersion. The suspension is centrifuged for the first time at a speed of 2000rpm, and the centrifugation time is 20min to remove the bottom sediment. Carry out the seco...

Embodiment 2

[0057] The specific process steps are basically the same as Example 1 of the present invention, and the difference with Example 1 is that in step 2), 1 kg of graphene oxide is added in 10 kg of 98 wt% concentrated sulfuric acid, and ultrasonic dispersion is obtained for 3 h to obtain a stable dispersion, and 3000 rpm is selected for use The bottom precipitation that centrifugal 40min obtains for the first time under rotating speed, ultrasonic dispersion obtains graphene oxide classification solution, step 3) adds 110kg 98wt% concentrated sulfuric acid, step 4) finally obtains graphene oxide content and is the graphene composite paraposition of 3wt% Aramid fiber.

Embodiment 3

[0059] The specific process steps are basically the same as in Example 1 of the present invention, and the difference with Example 1 is that in step 2), 1 kg of graphene oxide is added in 20 kg of 99 wt% concentrated sulfuric acid, ultrasonic dispersion is obtained for 2 h to obtain a stable dispersion, and 7000 rpm is selected for use Secondary supernatant after centrifugal 30min again under rotating speed, ultrasonic dispersion obtains graphene oxide classification solution, step 3) adds 47kg 99wt% concentrated sulfuric acid, step 4) finally obtains graphene oxide content and is the graphene composite pair of 3wt%. aramid fiber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com