Anticorrosive clothing material and protective garment made from anticorrosive clothing material

A fabric and slurry technology, applied in the field of protective clothing, can solve the problems of complex fabric composition and high cost, and achieve the effects of long service life, good mechanical strength, and broad market application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

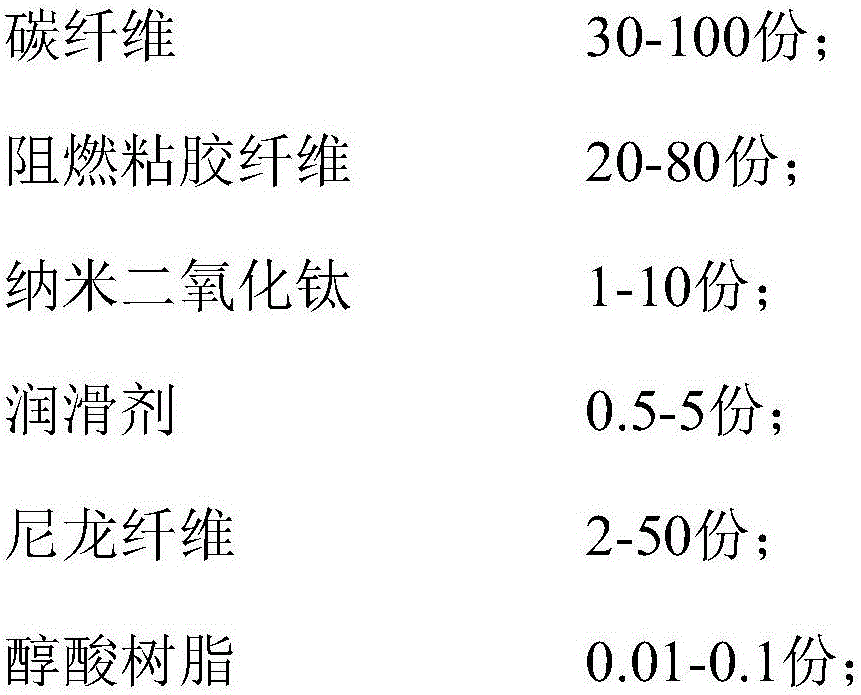

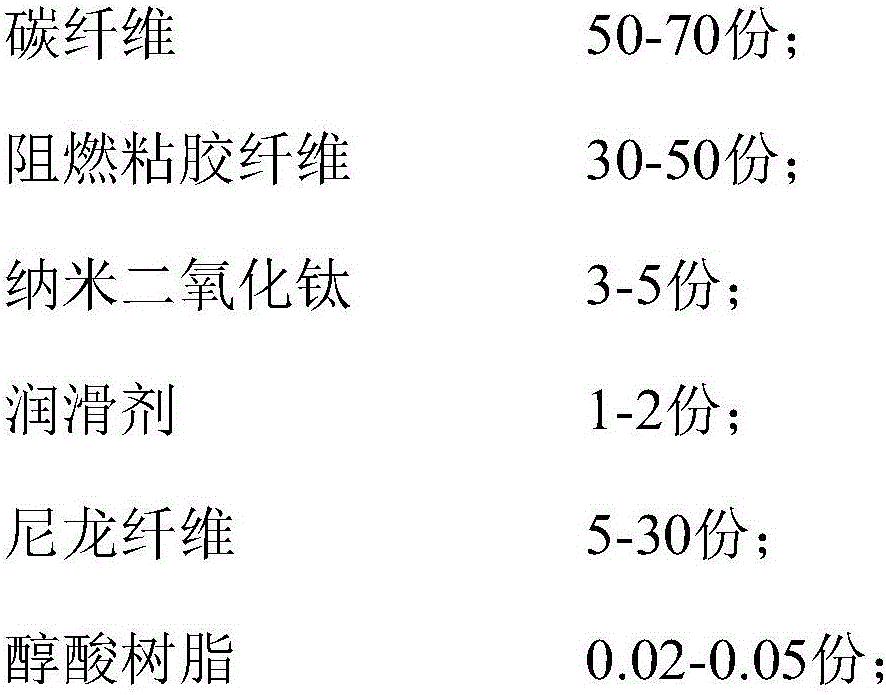

Method used

Image

Examples

Embodiment 1

[0055] A corrosion-resistant fabric, comprising the following components in parts by weight: carbon fiber 50; flame-retardant viscose fiber 30; nano-titanium dioxide 3; lubricant 1; nylon fiber 5; alkyd resin 0.02; toughening agent 5; graphene Carbon nanotube slurry 30, wherein the concentration of carbon nanotubes in the graphene carbon nanotube slurry is 60mg / mL, and the concentration of graphene is 0.5mg / mL;

[0056] The lubricant is polyacrylamide;

[0057] Flame retardant viscose fiber contains 8wt% full hydrogen silicone oil

[0058] The graphene carbon nanotube slurry is prepared by the following method: graphene, carbon nanotubes, and surfactant are dissolved in a mixture of water and an organic solvent and stirred;

[0059] The surfactant is sodium dioctyl sulfosuccinate;

[0060] Preferably, the surfactant is sodium dioctyl sulfosuccinate;

[0061] The amount of the surfactant is 3wt%;

[0062] The organic solvent is N,N-dimethylacetamide.

Embodiment 2

[0064] A corrosion-resistant fabric, comprising the following components in parts by weight: carbon fiber 70; flame-retardant viscose fiber 50; nano-titanium dioxide 5; lubricant 2; nylon fiber 30; alkyd resin 0.05; toughening agent 8; graphene Carbon nanotube slurry 40, wherein the concentration of carbon nanotubes in the graphene carbon nanotube slurry is 10mg / mL, and the concentration of graphene is 5mg / mL;

[0065] The lubricant is polyacrylamide;

[0066] The flame retardant viscose fiber contains 10wt% full hydrogen silicone oil;

[0067] The graphene carbon nanotube slurry is prepared by the following method: graphene, carbon nanotubes, and surfactant are dissolved in a mixture of water and an organic solvent and stirred;

[0068] The surfactant is a mixture of lauric acid diethanolamide and sodium dioctyl succinate sulfonate at a molar ratio of 1:1.5;

[0069] The amount of the surfactant is 3wt%;

[0070] The organic solvent is N,N-dimethylformamide.

Embodiment 3

[0072] A corrosion-resistant fabric, comprising the following components in parts by weight: carbon fiber 60; flame-retardant viscose fiber 40; nano-titanium dioxide 4; lubricant 1.5; nylon fiber 18; alkyd resin 0.04; toughening agent 6; graphene Carbon nanotube slurry 35, wherein the concentration of carbon nanotubes in the graphene carbon nanotube slurry is 30 mg / mL, and the concentration of graphene is 2 mg / mL.

[0073] The lubricant is polyacrylamide;

[0074] Flame retardant viscose fiber contains 10wt% full hydrogen silicone oil

[0075] The graphene carbon nanotube slurry is prepared by the following method: graphene, carbon nanotubes, and surfactant are dissolved in a mixture of water and an organic solvent and stirred;

[0076] The surfactant is a mixture of lauric acid diethanolamide and sodium dioctyl succinate sulfonate at a molar ratio of 1:1;

[0077] The amount of the surfactant is 4wt%;

[0078] The organic solvent is N,N-dimethylformamide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com