Preparation method of SiO2@C core-shell compound physical lithium ion battery cathode material

A lithium-ion battery and negative electrode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor electrochemical properties of electrode materials, complicated operation process, and non-environmental protection, and achieve excellent rate performance, environmental friendliness, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

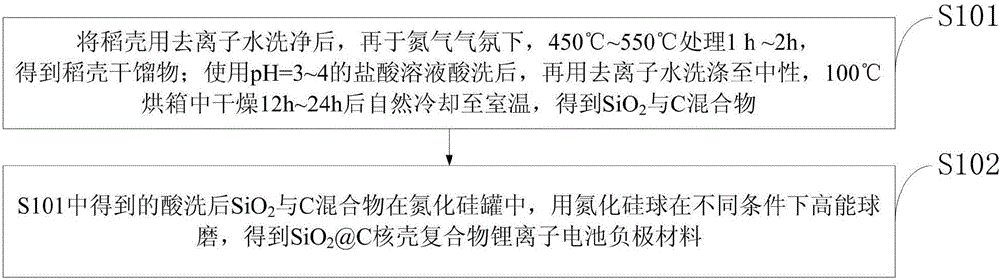

[0026] Such as figure 1 As shown, the SiO provided by the embodiment of the present invention 2 The preparation method of @C core-shell composite lithium ion battery negative electrode material specifically comprises the following steps:

[0027] S101: Wash the rice husk with deionized water, and then treat it at 450° C. to 550° C. for 1 h to 2 h under nitrogen atmosphere to obtain a dry distillate of rice husk; pickle with a hydrochloric acid solution with pH=3 to 4, and then use Wash with deionized water until neutral, dry in an oven at 100°C for 12h to 24h, then cool naturally to room temperature to obtain SiO 2 Mix with C.

[0028] SiO after pickling obtained in S102:S101 2 Mixed with C in a silicon nitride tank, high energy ball milling with silicon nitride balls under different conditions to obtain SiO 2 @C core-shell composite lithium-ion battery anode material.

[0029] In said S101, the rice husk is washed with deionized water to remove the alkali metal oxide imp...

Embodiment 1

[0035] Wash the rice husk with deionized water, calcined at 500°C for 1h under the protection of nitrogen atmosphere, then use 1.0mol / L hydrochloric acid solution, acid boil at 100°C for 2h, wash with deionized water until neutral, dry and cool naturally to room temperature to obtain SiO after pickling 2 / C mixture; according to the mass ratio of ball to material 10 / 1, the mixture is placed in a silicon nitride tank, the ball milling speed is set to 800rpm, the ball milling time is 12h, and silicon nitride balls are used for high energy ball milling to obtain the electrode material SiO 2 @C-12 core-shell complex.

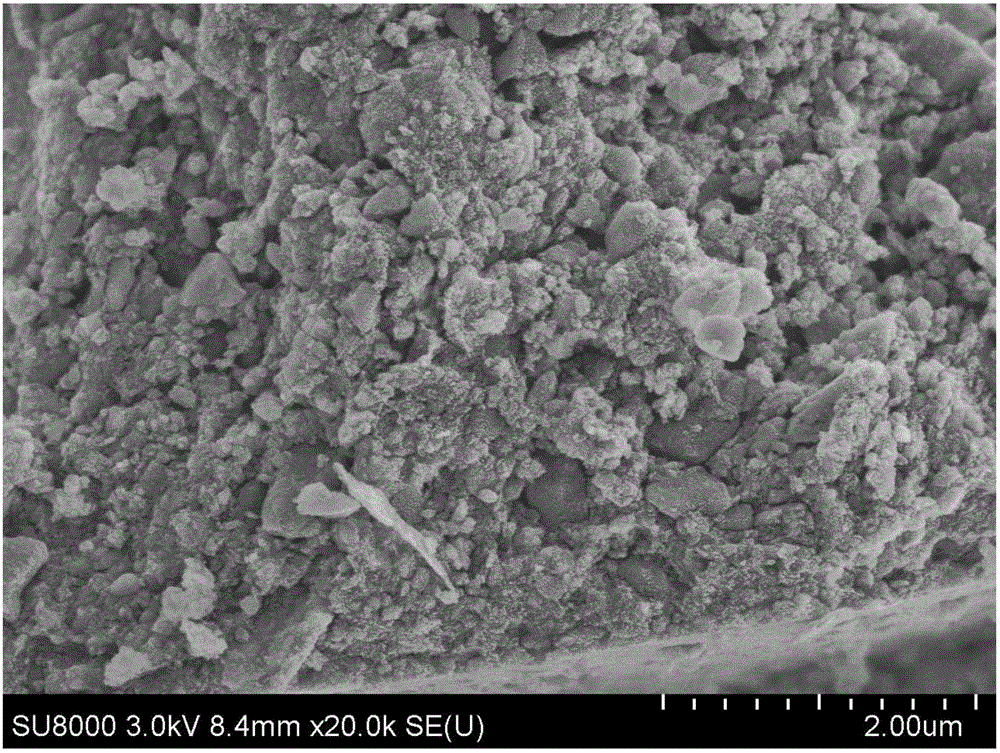

[0036] Prepared SiO 2 SEM image of @C core-shell complex, such as figure 2 shown.

[0037] The active electrode material (SiO 2 @C core-shell composite 80%), conductive agent (acetylene black 10%), and binder (PVDF10%) are evenly mixed, mixed and ground into a slurry using solvent NMP, and evenly coated on the current collector copper foil , after drying in a ...

Embodiment 2

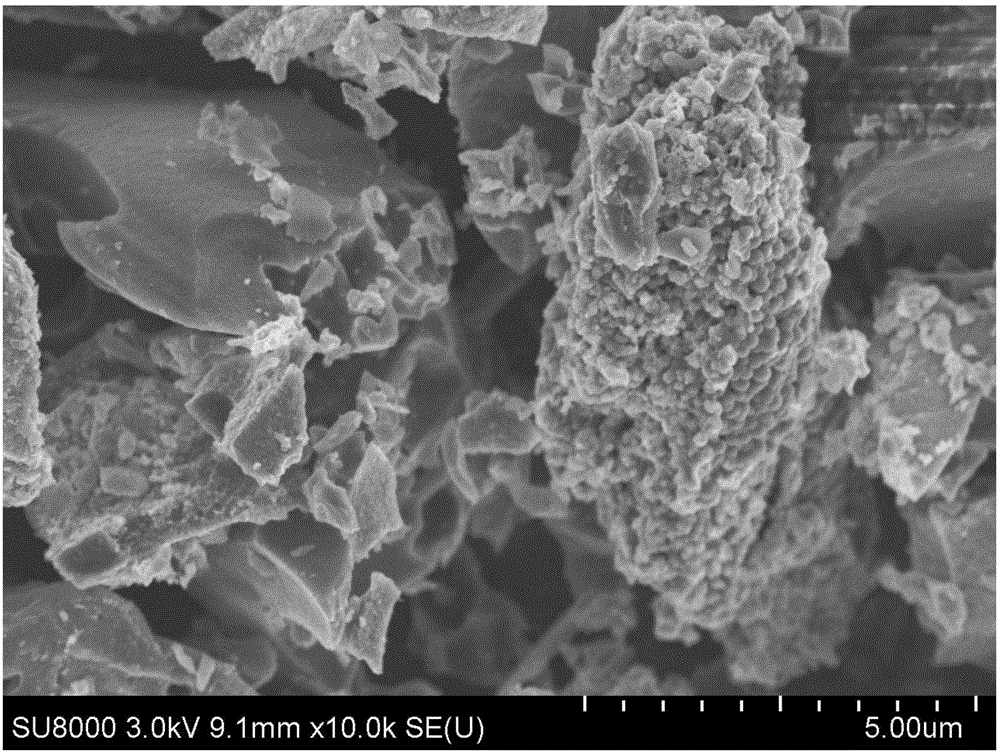

[0040] Prepare the sample according to the method described in Example 1, the difference is that the high-energy ball milling step is not carried out, that is, the ball milling time is 0h, and the obtained electrode material is SiO after pickling 2 / C mixtures such as image 3 Its SEM image.

[0041] The battery is assembled according to the method of Example 1, and the battery is measured at a current density of 100mA / g, the first discharge specific capacity is 631mAh / g, and the specific capacity after 100 cycles is 462mAh / g, and the cycle performance is as follows: Figure 5 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| First discharge specific capacity | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com