High-security lithium ion batteries and preparation method thereof

A lithium-ion battery and negative electrode technology, which is applied in the manufacture of electrolyte batteries, secondary batteries, secondary battery components, etc., can solve the problems that the safety performance of batteries cannot meet the needs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

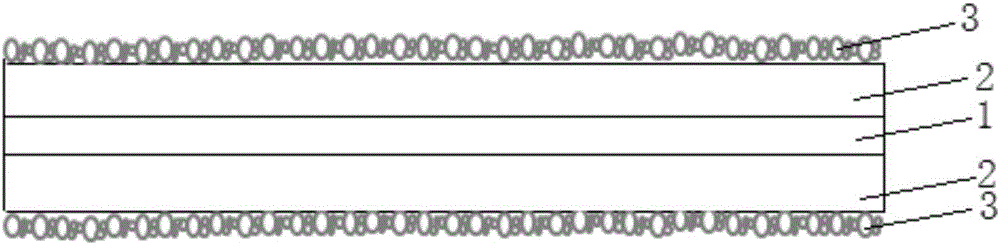

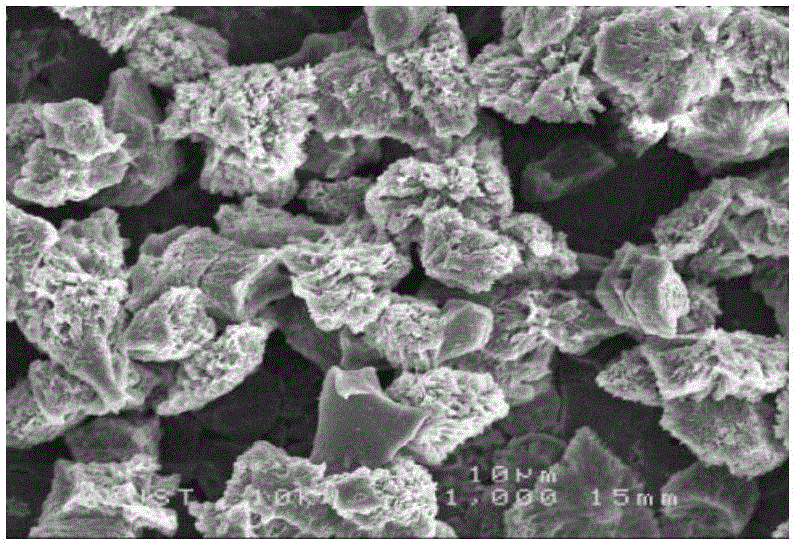

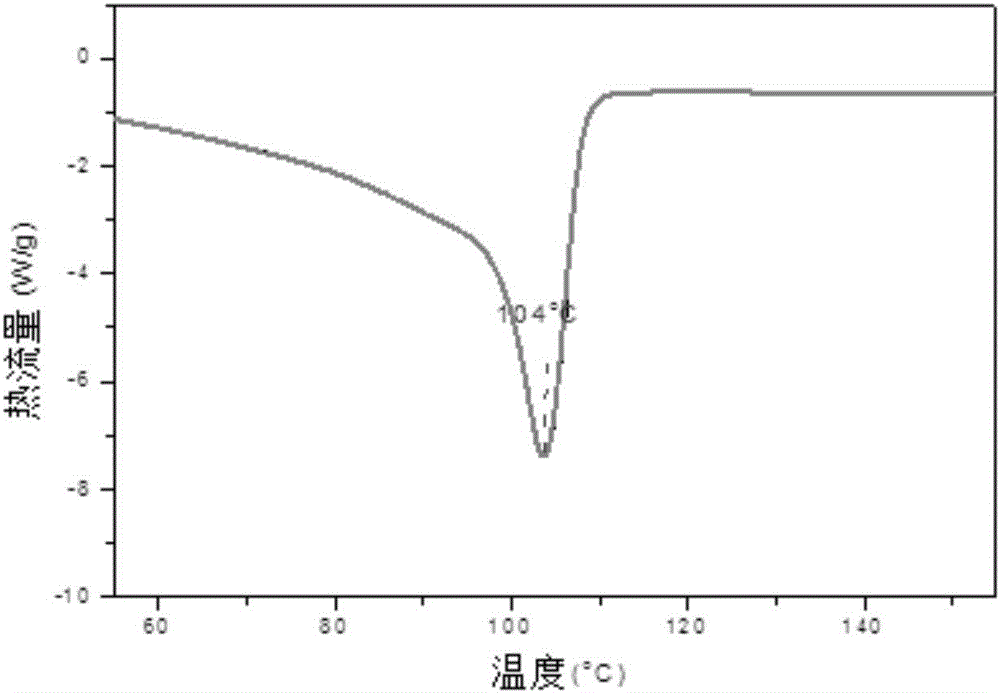

[0025] First, the negative electrode sheet is prepared according to the conventional lithium-ion battery negative electrode sheet preparation process. The negative electrode sheet includes a current collector and a carbon layer coated on the current collector. The carbon layer is graphite layer, hard carbon material layer or soft carbon material layer. Any one, including taking nanoparticles and dispersing them in the binder solution to configure a latex solution, the melting point of the nanoparticles is 90-110°C, the nanoparticles can be hyperbranched polymers or dendritic polymers, Preferably, the nanoparticles are polyethylene, polypropylene, low-density polyethylene, ethylene-octene copolymer, ethylene-vinyl acetate copolymer, ethylene-acrylic acid copolymer, chlorinated polyethylene, polyvinyl chloride, thermoplastic polyurethane Any one of elastomers, in this embodiment, the nanoparticles are polyethylene nanoparticles, and the binder is any one of styrene-butadiene rubb...

Embodiment 2

[0036] First, the negative electrode sheet is prepared according to the conventional lithium-ion battery negative electrode sheet preparation process. The negative electrode sheet includes a current collector and a carbon layer coated on the current collector. The carbon layer is graphite layer, hard carbon material layer or soft carbon material layer. Either, comprising then getting the nanoparticles of ethylene-vinyl acetate copolymer dispersed in the binder solution, configured into a latex solution, the binder described in this embodiment is sodium carboxymethyl cellulose, and then using Any coating process such as extrusion coating, transfer coating, spray coating, etc. coats the latex solution on the surface of the carbon layer of the negative electrode sheet, and dries to obtain an ethylene-vinyl acetate copolymer coating. The ethylene-vinyl acetate The thickness of the ester copolymer coating is 5-10 μm. The lithium-ion battery cells prepared in Example 2 and Comparati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com