A green recycling method and equipment for the pretreatment of waste lithium-ion batteries

A lithium-ion battery, recycling and processing technology, applied in the field of green recycling and processing methods and equipment for the pretreatment of waste lithium-ion batteries, can solve the problems of not taking into account, not taking into account secondary pollution, increasing the difficulty of wastewater treatment, and avoiding pollution. , avoid secondary pollution problems, save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

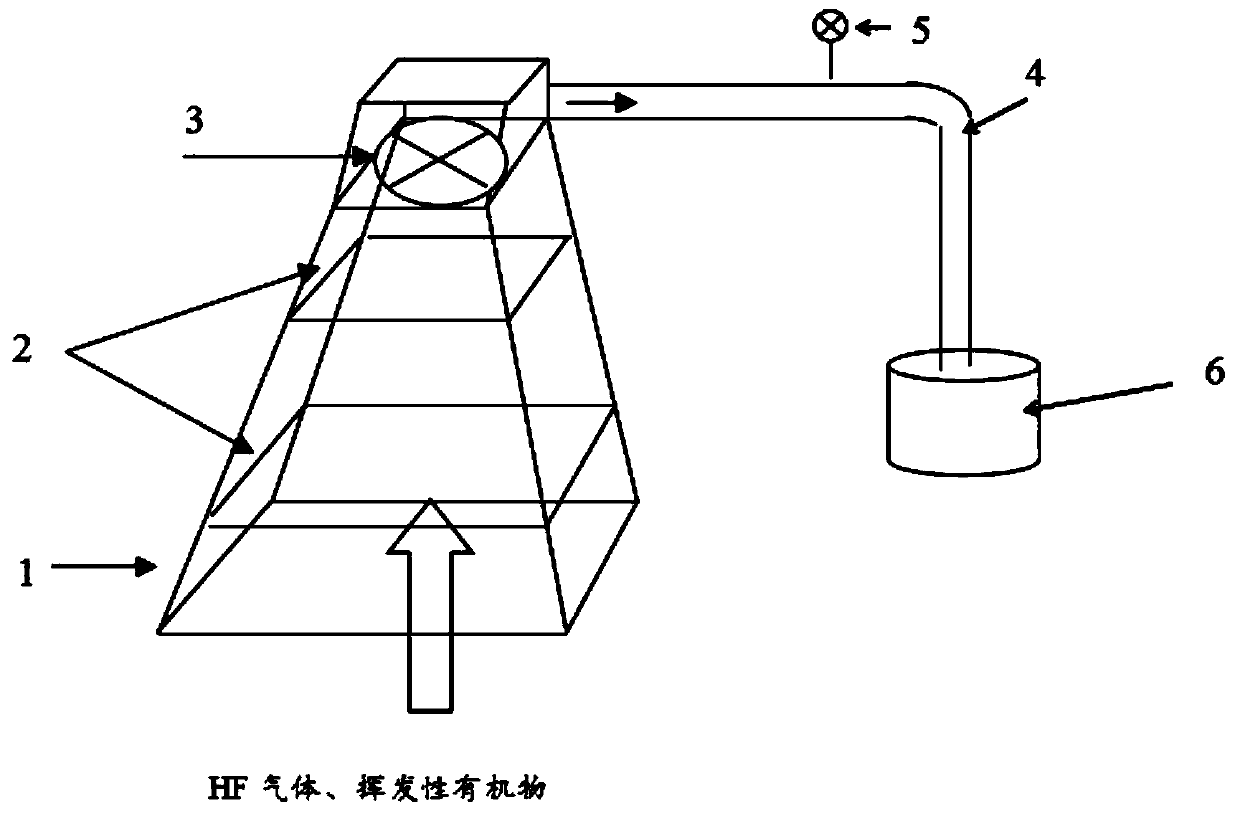

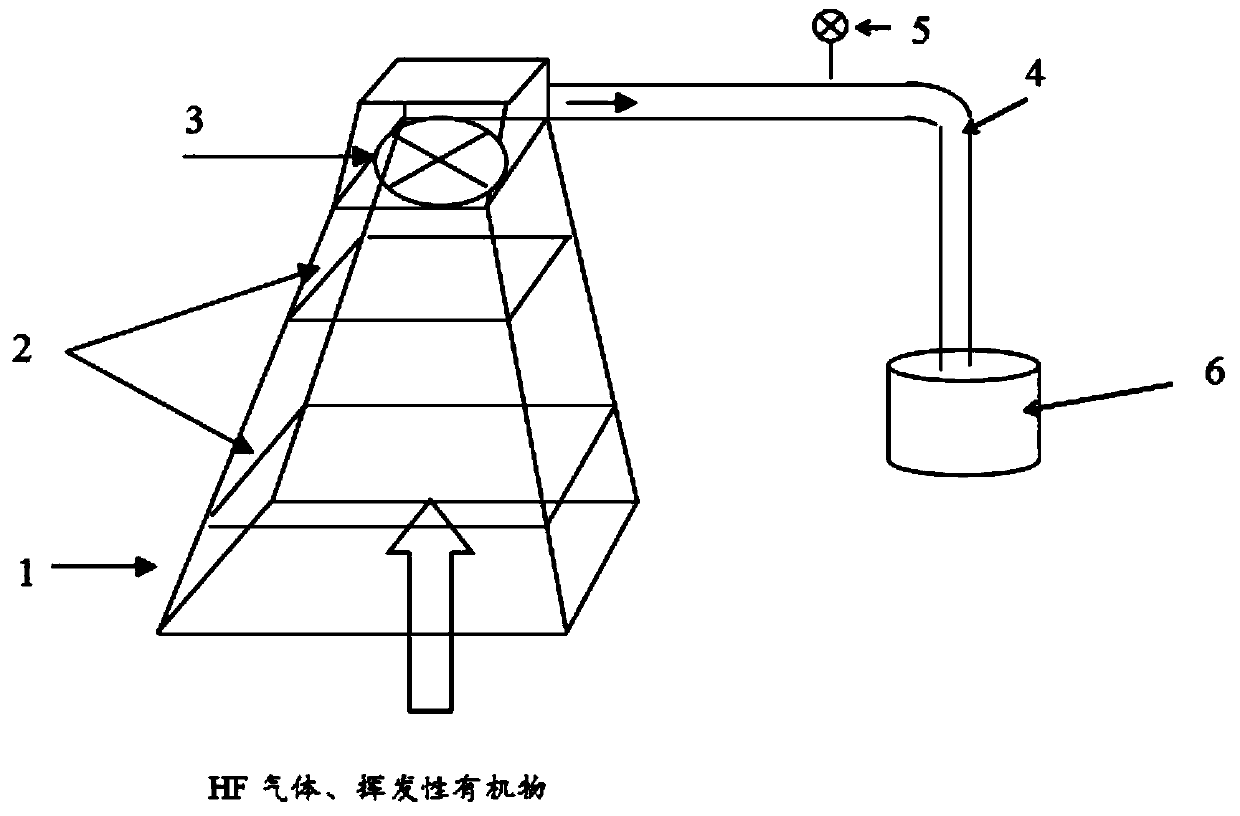

[0042] Soak 100g of used lithium-ion batteries in 10% NaCl solution for 24 hours for complete discharge treatment, rinse with clean water, and air dry. Grind 800g of the mixture of sodium fluoride and barium fluoride into fine powder of 100 mesh, add it to 1000g of diatomite with a pore size of about 0.8mm and mix, then add 500mL of water to the mixture and stir, and transfer to Air-dried for 24 hours in the carrier board of the hollow mesh structure. Clamp the formed adsorbent bearing plate (2) into the movable slot inside the conical box (1). Put the air-dried waste lithium-ion battery in the crusher, start the motor and turn on the air extraction system at the same time, adjust the power of the air extraction machine (3) to 400W, at this time the gas detector (5) in the air duct (4) reads as 0.03mg / L. The other end of the airway extends into the absorption liquid, so that the gas in the airway is absorbed by the absorption liquid.

[0043] It shows that the technical sol...

Embodiment 2

[0045] Soak 300g of used lithium-ion batteries in 10% NaCl solution for 24 hours for complete discharge treatment, rinse with clean water, and air dry. Grind 800g of the mixture of sodium fluoride and barium fluoride into fine powder of 100 mesh, add it to 1000g of diatomite with a pore size of about 0.8mm and mix, then add 500mL of water to the mixture and stir, and transfer to Air-dried for 24 hours in the carrier board of the hollow mesh structure. Clamp the formed adsorbent bearing plate (2) into the movable slot inside the conical box (1). Put the air-dried waste lithium-ion battery in the crusher, start the motor and open the air extraction system at the same time, adjust the power of the air extraction machine (3) to 500W, at this time the gas detector (5) in the air duct (4) shows 0.08mg / L. The other end of the airway extends into the absorption liquid, so that the gas in the airway is absorbed by the absorption liquid.

[0046] It shows that the technical solution ...

Embodiment 3

[0048] Soak 500g of used lithium-ion batteries in 5% NaCl solution for 48 hours for complete discharge treatment, rinse with clean water, and air dry. Grind 600g of calcium fluoride into 100-mesh fine powder, add it to 600g of activated carbon particles with a pore size of about 0.5mm, and mix, then add 400mL of water to the mixture and stir, and transfer it to a hollow mesh-shaped carrier plate after being evenly blended Medium, air-dried for 24 hours to shape. Clamp the formed adsorbent bearing plate (2) into the movable slot inside the conical box (1). Put the air-dried waste lithium-ion battery in the crusher, start the motor and open the air extraction system at the same time, adjust the power of the air extraction machine (3) to 600W, at this time, the gas detector (5) in the air duct (4) shows as 0.12mg / L. The other end of the airway extends into the absorption liquid, so that the gas in the airway is absorbed by the absorption liquid.

[0049] It shows that the tech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com