Preparation method and application of active carbon supported nanometer Fe-Al (hydr)oxide particle composite material

A technology of oxide particles and composite materials, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc., can solve the problem of insignificant phosphate adsorption, and achieve low production cost and high adsorption capacity. , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

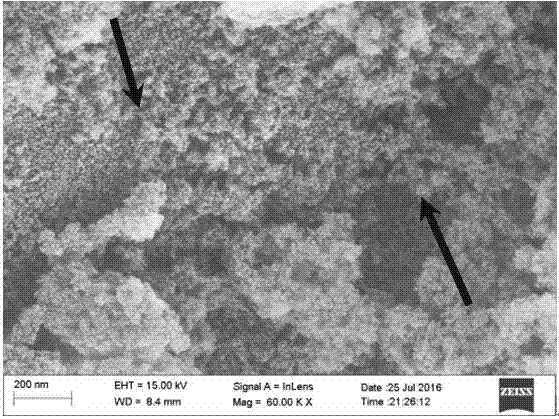

[0023] FeCl 3 ·6H 2 O and AlCl 3 ·6H 2 O was dissolved in 50ml deionized water to prepare Fe 3+ and Al 3+ Mixed solution, Fe in the mixed solution 3+ with Al 3+ The molar ratio of the solution is 9:1. Put 200ml of deionized water in a beaker and heat to boil. Add the mixed salt solution dropwise into the boiled deionized water and stir while controlling the pH of the solution in the neutral range. The solution was continuously heated until a brown Fe–Al hydroxide sol was formed, the concentration of the sol was 1mol / L, and then the sol was cooled to room temperature, and 1.5g of activated carbon was added to the sol for 30 minutes of ultrasonication, and the solution was placed in a constant temperature water bath at 75°C. Rotary evaporation in a medium to powder form, repeated washing with deionized water, and drying at 105°C to obtain a composite material, which is designated as "1.5AC-Fe / Al". figure 1 For the scanning electron micrograph of this composite material 1....

Embodiment 2

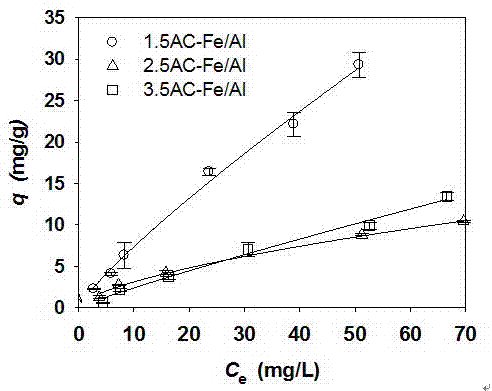

[0035] The 1.5AC-Fe / Al material prepared in Example 1 weighed 0.04g in a series of Erlenmeyer flasks, and then added 40ml of KH with a mass concentration of 5, 10, 20, 40, 60, 80mg / L 2 PO 4 Solution (background solution is pH=3, contains 10mmol / LNaCl and 5mmol / LCaCl 2), sealed and placed in a constant temperature oscillator, and oscillated at a rate of 180r / min at a temperature of (20±0.5°C) for 48h (the adsorption equilibrium time has been determined in advance). Then put it on a flat surface and let it settle overnight to allow the adsorbent to settle and then filter the supernatant with a 0.45um membrane filter. The adsorption amount of phosphorus is determined by the difference between the adsorption equilibrium and the initial concentration, and is determined by the ammonium molybdate colorimetric method . Phosphorus adsorption capacity (q, mg / g) and partition coefficient (K d ,L / g) is calculated by the following formula:

[0036] q=V(C 0 -C e ) / m (1)

[0037] K d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com