Alumina carbonyl sulfide hydrolysis catalyst and preparation method thereof

A hydrolysis catalyst, alumina technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as activity decline, and achieve the effect of avoiding pore reduction and good COS hydrolysis conversion activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

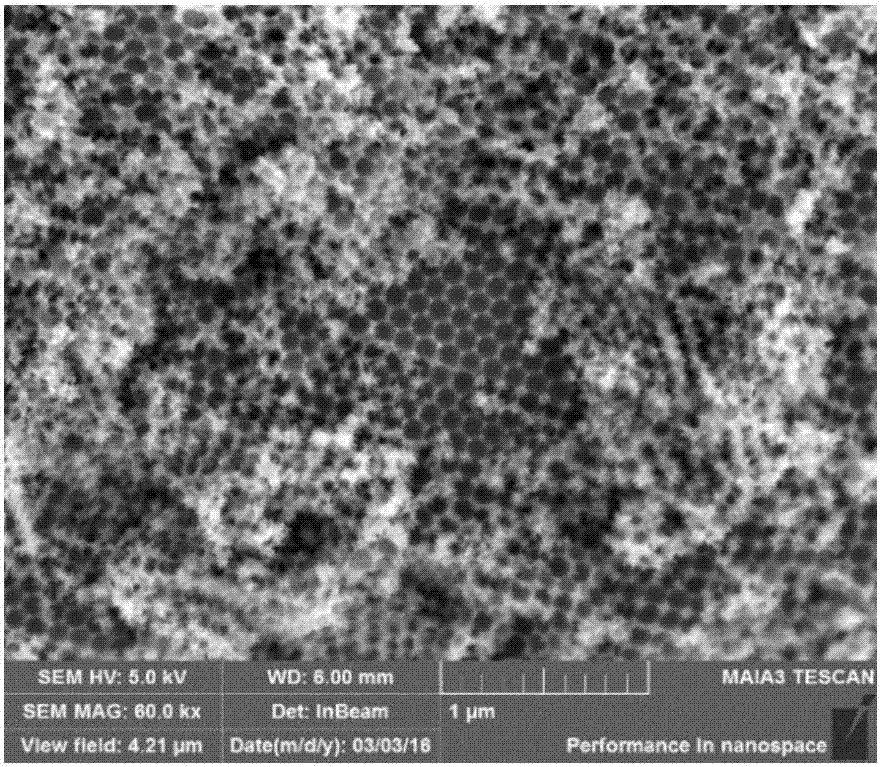

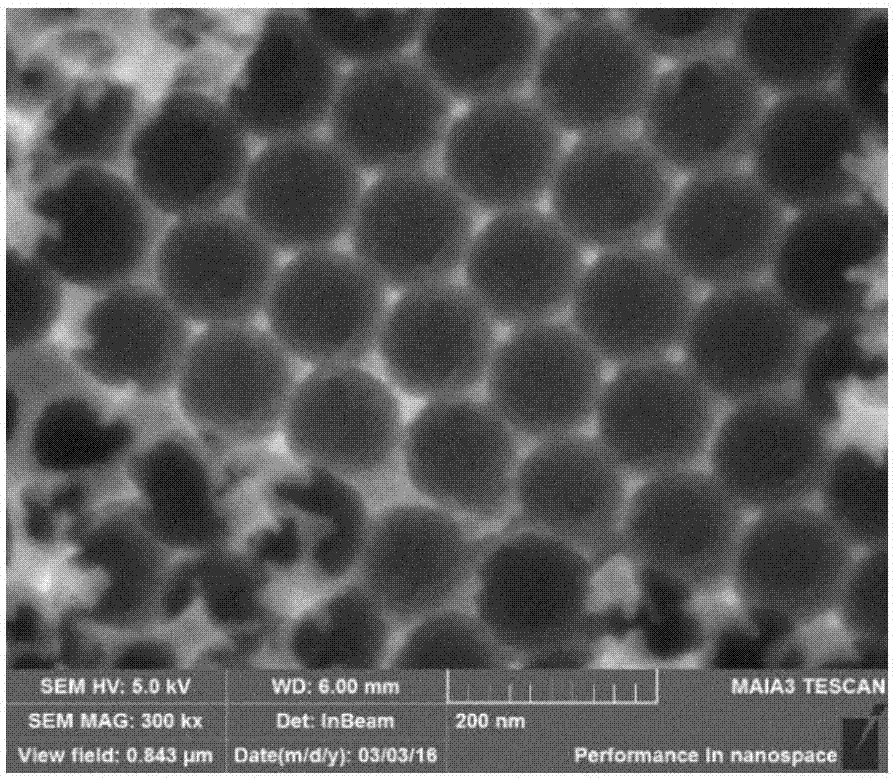

[0045] like Figure 1a and Figure 1b As shown, the alumina carbonyl sulfide hydrolysis catalyst is a step-pore alumina-based catalyst, and the step-pore alumina-based catalyst has macropores, mesopores and micropores and is loaded with K 2 CO 3 (Potassium Carbonate) as a stepped pore catalyst.

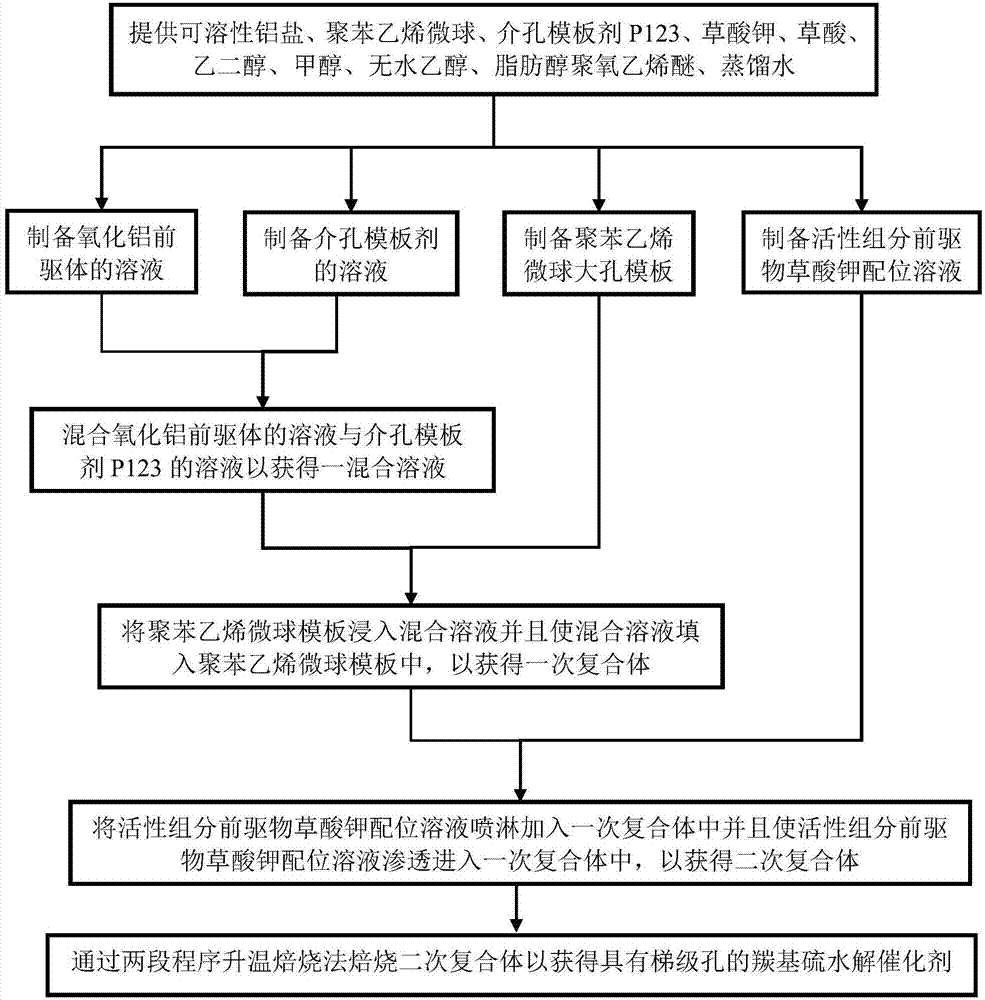

[0046] like figure 2 As shown, it shows the process flow of the method for preparing alumina carbonyl sulfide hydrolysis catalyst according to Embodiment 1 of the present invention. The method includes the following steps:

[0047] (1) Provide soluble aluminum salt, polystyrene microspheres, mesoporous template agent P123, potassium oxalate, oxalic acid, ethylene glycol, methanol, absolute ethanol, fatty alcohol polyoxyethylene ether, distilled water, among which in this example poly Styrene microspheres select monodisperse polystyrene microsphere emulsion for use, and distilled water can be replaced by deionized water. Those skilled in the art should understand that polystyrene ...

Embodiment 2

[0072] The chemical materials used in Example 2 of the present invention are: aluminum nitrate nonahydrate, monodisperse polystyrene microsphere emulsion, mesoporous template agent P123, ethylene glycol, methanol, and absolute ethanol.

[0073] The concrete preparation method of the aluminum oxide carbonyl sulfide hydrolysis catalyst of embodiment two is as follows:

[0074] (1) Prepare the solution of alumina precursor

[0075] Weigh 37.82g±0.001g of aluminum nitrate nonahydrate, measure 20mL±0.01mL of methanol, and measure 30mL±0.01mL of ethylene glycol; All placed in a beaker, then stirred with a stirrer until completely dissolved to obtain an aluminum solution with a concentration of 2mol / L;

[0076] (2) Preparation of the solution of the mesoporous templating agent

[0077] Accurately weigh 25.00g ± 0.001g of mesoporous template agent P123, and then dissolve the weighed P123 in 50mL of absolute ethanol to obtain a solution of mesoporous template agent (P123);

[0078] ...

Embodiment 3

[0083] The chemical materials used in Example 3 of the present invention are: aluminum nitrate nonahydrate, monodisperse polystyrene microsphere emulsion, mesoporous template agent P123, potassium carbonate, ethylene glycol, methanol, absolute ethanol and distilled water.

[0084] The concrete preparation method of the aluminum oxide carbonyl sulfide hydrolysis catalyst of embodiment three is as follows:

[0085] (1) Prepare the solution of alumina precursor

[0086]Weigh 37.82g±0.001g of aluminum nitrate nonahydrate, measure 20mL±0.01mL of methanol, and measure 30mL±0.01mL of ethylene glycol; All placed in a beaker, then stirred with a stirrer until completely dissolved to obtain an aluminum solution with a concentration of 2mol / L;

[0087] (2) Preparation of the solution of the mesoporous templating agent

[0088] Accurately weigh 25.00g ± 0.001g of mesoporous template agent P123, and then dissolve the weighed P123 in 50mL of absolute ethanol to obtain a solution of mesopo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Total pore volume | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com