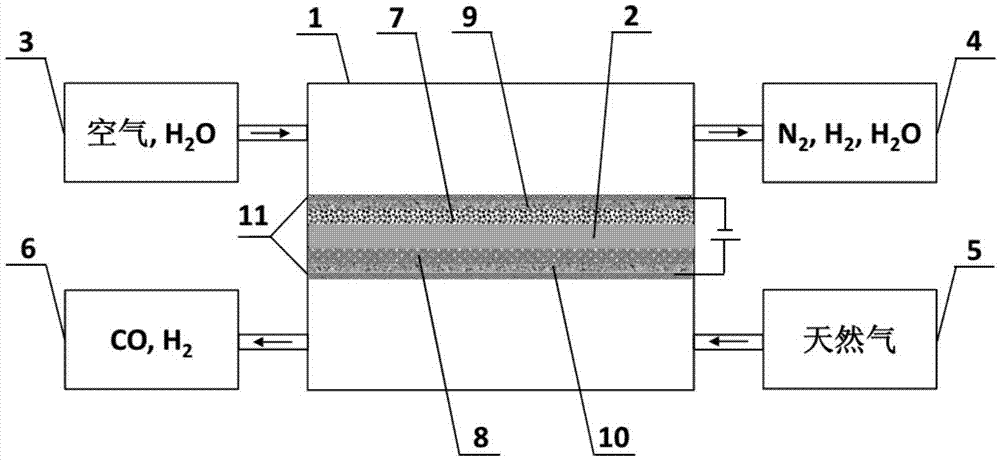

System and method for simultaneously preparing ammonia synthesis gas and liquid fuel synthesis gas

An ammonia synthesis gas and liquid fuel technology, which is applied to liquid carbon-containing fuels, fuels, cells, etc., can solve problems such as explosion and temperature flying, and achieves the reduction of processes, high reaction conversion rate and selectivity, and resource and energy saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

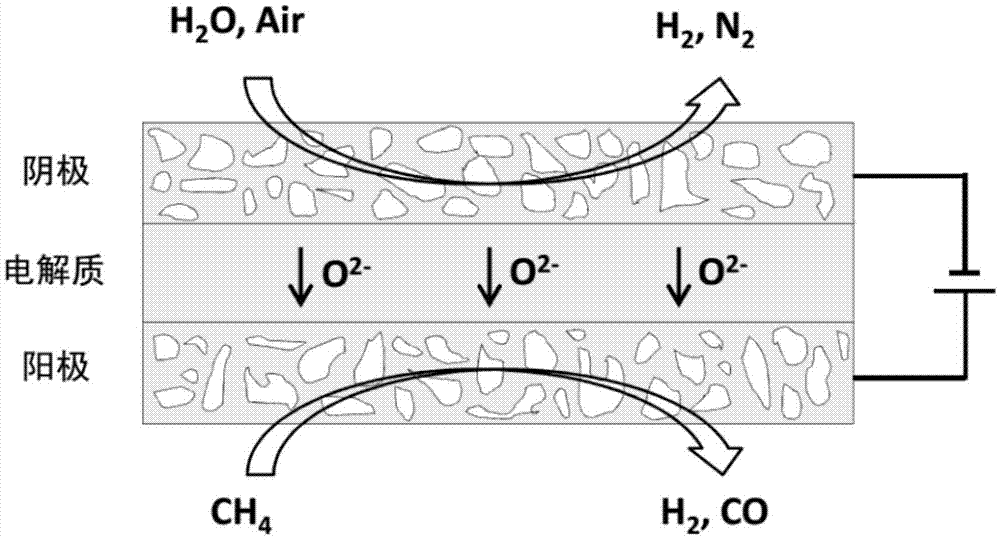

Embodiment 1

[0087] The electrolytic cell adopts the 200-micron 8YSZ (YSZ, purchased from Japan Tosoh Co., Ltd.) dense film with a thickness of 200 microns as the electrolyte, and the 50-micron porous 45wt.% NiO-YSZ (Ni-YSZ) prepared by the tape-casting method Is the cathode (the cathode is prepared according to the method reported in the document Zhang XM, et al.Enhanced oxygen reduction activity and solid oxide fuel cell performance with a nanoparticles-loaded cathode. Nano Lett2015; 15, 1703-1709.), tape-casting prepared 50 micron porous La 0.8 Sr 0.2 MnO 3 (LSM, powder purchased from Praxair) membrane was used as the cathode, and the nickel mesh was used as the current-collecting layer. Both cathode and anode sides of the electrolytic cell are filled with 40wt.% Ni-YSZ (Ni-YSZ) catalyst prepared by impregnation method, and the electrolytic cell filled with the catalyst is sealed in the electrolytic cell assembly at 961°C with a silver ring. The effective area of the electrolytic c...

Embodiment 2

[0090] The electrolytic cell adopts a YSZ dense film with a thickness of 350 microns prepared by casting method as the electrolyte, and both the cathode and the anode use composite electrodes. The cathode is a porous YSZ cathode impregnated with 5wt.% Rh / LSM catalyst, and the anode is impregnated with 20wt.% Ni / LSM porous YSZ anode, the porosity of the YSZ electrode framework is 40%. The gold mesh serves as the current-collecting layer. The cathode side of the electrolytic cell is filled with 5wt.%Rh / LSM catalyst, and the electrolytic cell filled with the catalyst is sealed in the electrolytic cell assembly at 961° C. with a silver ring. The effective area of the electrolytic cell is 1cm 2 .

[0091] After slowly cooling down to 800°C, 50mL min was passed through the cathode side -1 H 2 O and 3.7mL min -1 The mixed raw material gas of air, 9.8mL min is passed through the anode side -1 methane to produce liquid fuel syngas. A voltage of 1.6V was applied between the ano...

Embodiment 3

[0093] The Sm with a thickness of 500 μm was prepared by dry pressing in the electrolytic cell 0.2 Ce 0.8 o 1.9 (SDC, the powder was purchased from Praxair Surface Technology Co., Ltd.) The dense membrane was used as the electrolyte, and the porous SDC prepared by dry pressing method with carbon powder as the pore-forming agent was used as the cathode electrode skeleton. The cathode was a porous SDC cathode impregnated with 5 wt.% Ru / LSM catalyst. The anode is porous Sr impregnated with 5wt.% Pt / LSM catalyst 0.8 co 0.8 Fe 0.2 o 3-δ (SCF, powder is synthesized according to the method reported in Zhu KY, et al. Enhanced performance of solid oxide fuel cells by introducing a transition layer between nanostructured cathode and electrolyte. Int J HydrogenEnergy 2015; 40, 501-508.) anode. Platinum mesh acts as the current collecting layer. The anode side of the electrolytic cell was filled with a 5wt.% Ru / LSM catalyst prepared by impregnation, and the electrolytic cell filled...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com