Self-assembly three-dimensional copper Raman enhanced substrate, and preparation method and application thereof

A self-assembly, three-dimensional technology, applied in the direction of Raman scattering, measuring devices, instruments, etc., can solve problems affecting the accuracy and sensitivity of Raman spectroscopy, complex pre-processing processes, etc., to achieve the effect of reducing application costs and overcoming high costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

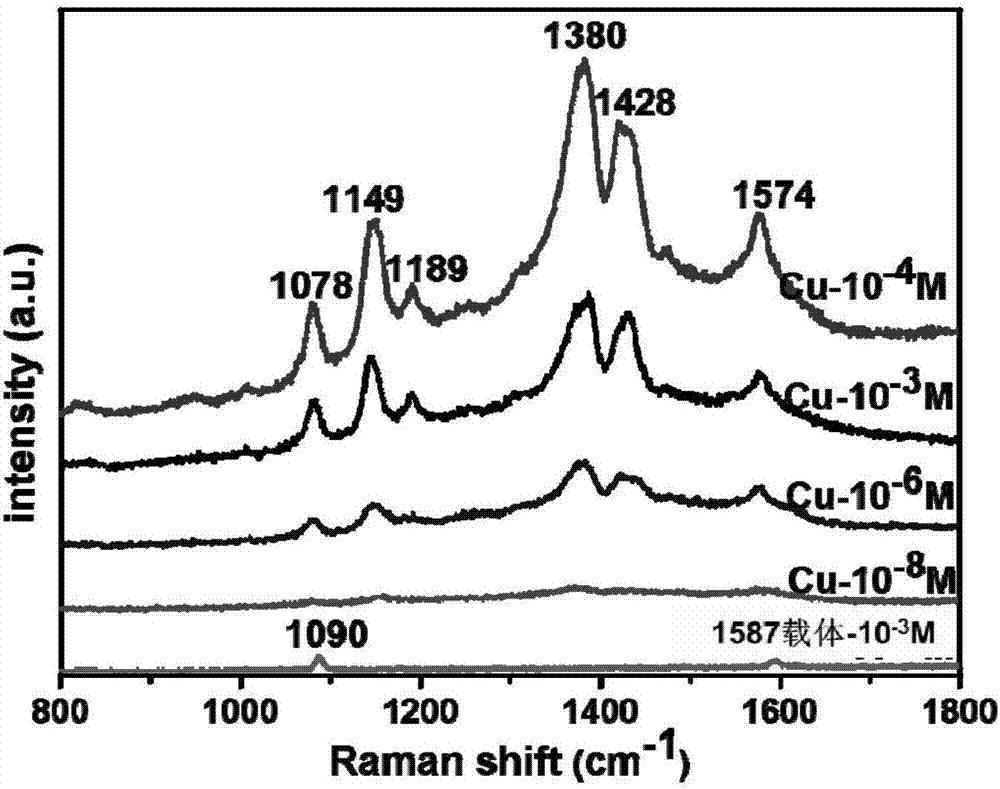

Examples

Embodiment 1

[0048] (1) Mix 0.1g chitosan with 0.1g citric acid, dissolve in 1% vt glacial acetic acid solution, set the volume to 100mL, transfer to a polytetrafluoroethylene hydrothermal reaction kettle, react at 100°C for 2h, and obtain citric acid Carbon dot 100mL;

[0049] (2) Add 80 mg of sodium hydroxide to 20 mL of 0.1 mol / L copper acetate solution, mix 10 mL of the carbon dot solution obtained, and set the volume to 80 mL to obtain a mixed solution;

[0050] (3) 0.14mL of 35%wt hydrazine hydrate, stirred at 50°C for 2h, centrifuged at 9800rpm for 15min six times after the reaction was completed, and after separation, vacuum-dried at room temperature to obtain copper powder;

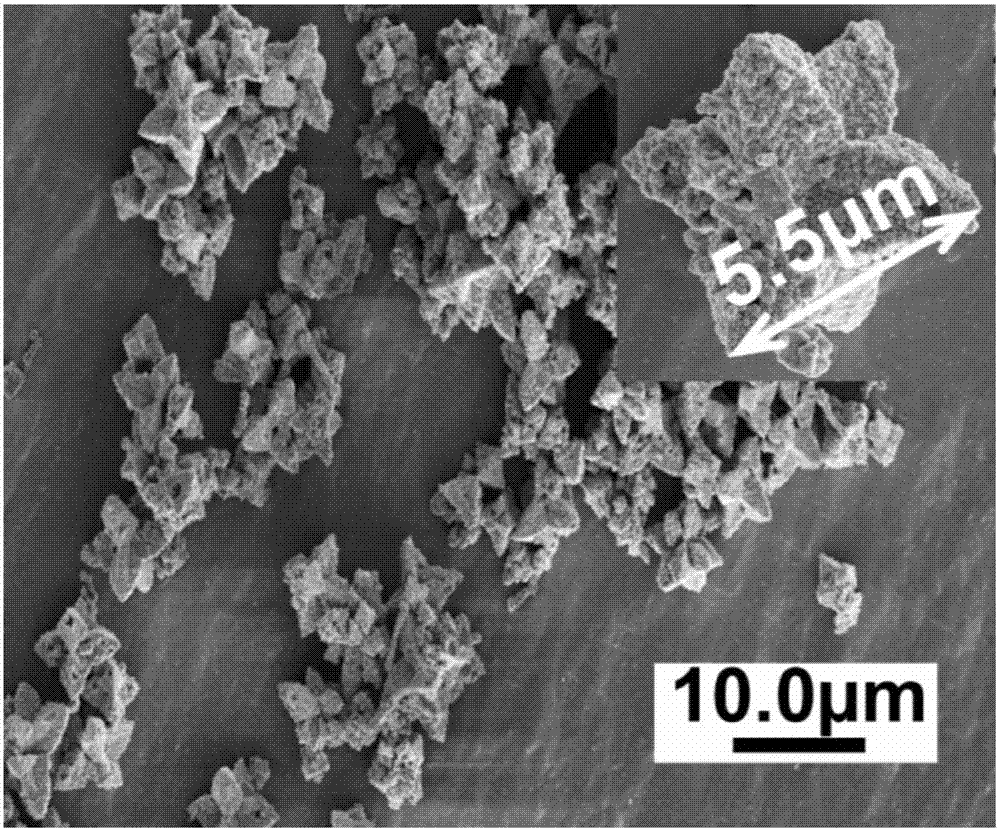

[0051] (4) In step (3), the copper powder is ultrasonically oscillated in an aqueous solution to prepare a suspension of 1 mg / mL, quickly put the cleaned glass flakes in the suspension, let it stand for 48 hours, take out the glass flakes, and vacuum Drying to obtain a self-assembled three-dimensional copper...

Embodiment 2

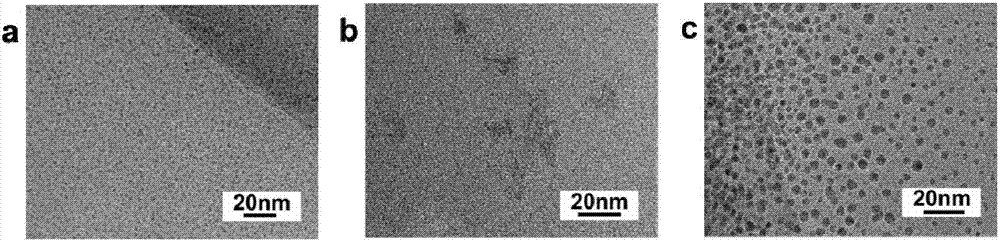

[0053](1) 0.1g chitosan mixed with 0.4g citric acid, dissolved in 1% vt glacial acetic acid solution, fixed to 100mL, transferred to a polytetrafluoroethylene hydrothermal reaction kettle, reacted at 150°C for 12h to obtain citric acid Carbon dot 100mL; its transmission electron microscope picture is as follows figure 1 (c) shown.

[0054] (2) 0.36g of copper acetate, mixed with 80mL of carbon dot solution obtained, added 8g of sodium hydroxide, stirred evenly to obtain a mixed solution;

[0055] (3) 0.28mL of 35%wt hydrazine hydrate, stirred at 80°C for 2h, centrifuged at 9800rpm for 15min six times after the reaction was completed, and after separation, vacuum-dried at room temperature to obtain copper powder;

[0056] (4) In step (3), the copper powder is ultrasonically oscillated in an aqueous solution to prepare a suspension of 5 mg / mL, and the cleaned glass flakes are quickly placed in the suspension, and left to stand for 48 hours, the glass flakes are taken out, and v...

Embodiment 3

[0058] (1) Mix 0.1g of chitosan with 0.5g of citric acid, dissolve in 1% vt glacial acetic acid solution, set the volume to 100mL, transfer to a polytetrafluoroethylene hydrothermal reaction kettle, and react at 200°C for 6h to obtain citric acid Carbon dot 100mL;

[0059] (2) 2mL of 0.1mol / L copper chloride solution, add 20g of sodium hydroxide, mix 2mL of the obtained carbon dot solution, and set the volume to 80mL to obtain a mixed solution;

[0060] (3) 0.056mL of 35%wt hydrazine hydrate, stirred at 80°C for 6h, centrifuged at 9800rpm for 15min six times after the reaction was completed, and after separation, vacuum-dried at room temperature to obtain copper powder;

[0061] (4) In step (3), the copper powder is ultrasonically oscillated in an aqueous solution to prepare a suspension of 10 mg / mL, quickly put the cleaned glass flakes in the suspension, let it stand for 48 hours, take out the glass flakes, and vacuum Drying to obtain a self-assembled three-dimensional coppe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com