Resistor type acetone sensor based on graphitizing carbonized nitrogen/stannic oxide composite material, preparation method, and application thereof

A technology of tin dioxide and composite materials, which is applied in the fields of material resistance, material analysis, and material analysis through electromagnetic means, and can solve the problems of inability to detect acetone, poor thermal stability of graphene, and restrictions on wide application and promotion. Achieve good response reversibility, improve performance, and improve sensitive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

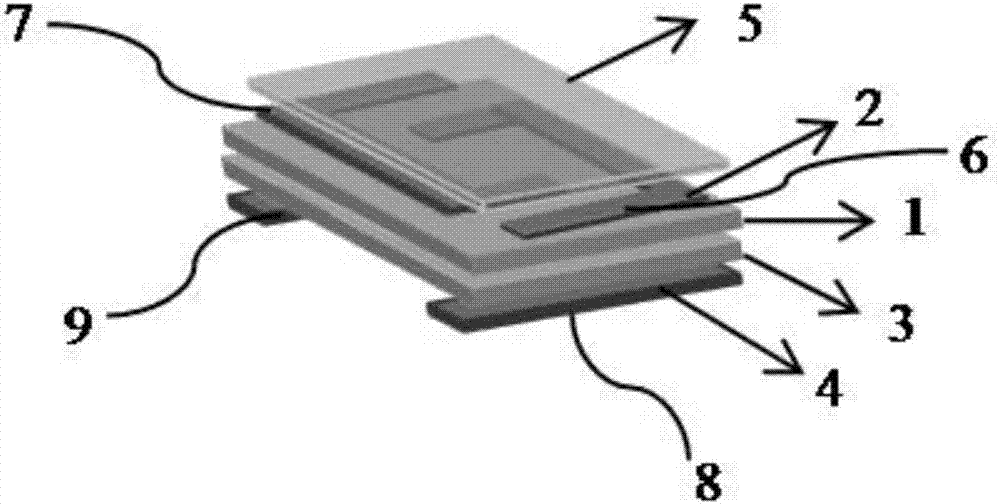

[0029] (1) A pair of U-shaped gold electrodes with interdigital structure are printed on the upper surface of the ceramic sheet by using a ceramic sheet as a substrate. The gold electrode has a width of 200 μm and a thickness of 10 μm; under the ceramic sheet A layer of ruthenium dioxide is flatly printed on the surface as a heating layer, the thickness of the ruthenium dioxide is 20μm; a pair of strip-shaped gold electrodes are printed on the surface of the ruthenium dioxide layer, the width of the gold electrode is 400μm and the thickness is 10μm;

[0030] (2) Ultrasonic cleaning the upper surface of the ceramic sheet and the U-shaped gold electrode surface obtained in step (1) with ethanol and water, and drying;

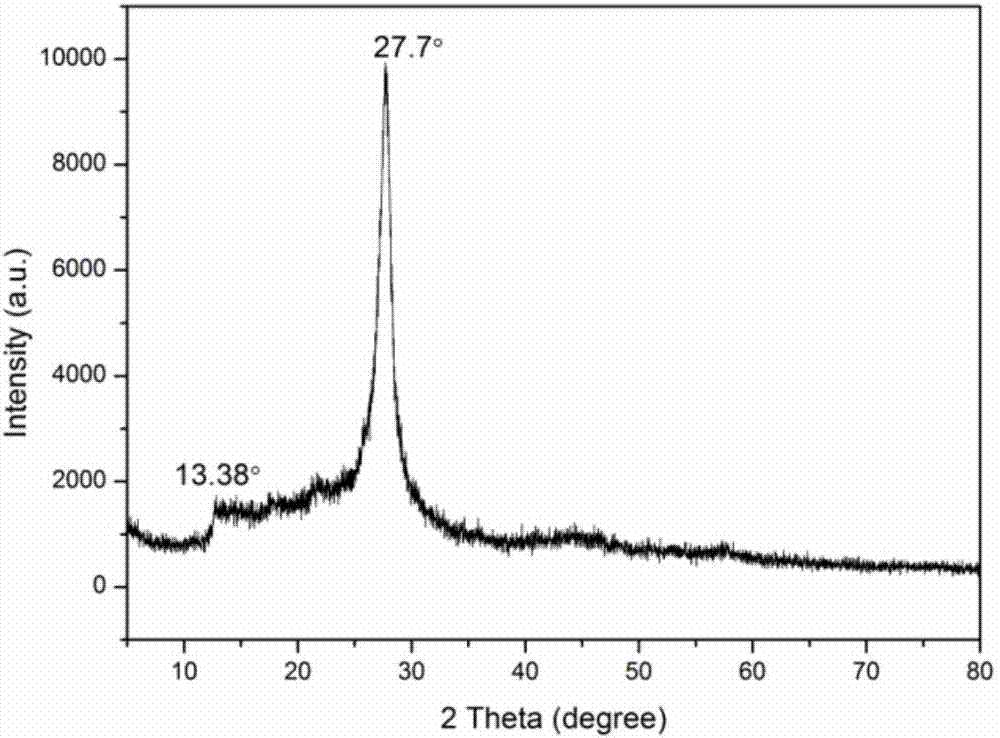

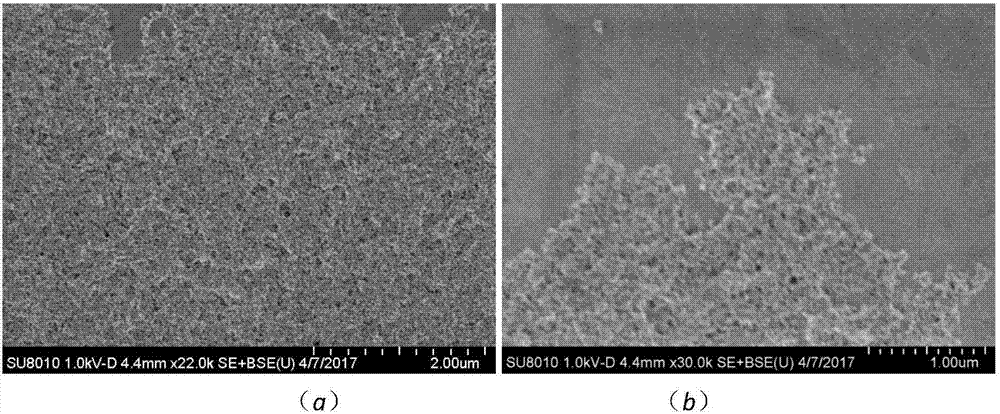

[0031] (3) Prepare 5 mL of a nitrogen carbide aqueous solution with a concentration of 0.1 mg / mL, then add 0.023 mg of tin tetrachloride, and ultrasonically disperse to make it fully mixed to obtain a composite solution of carbon, nitrogen and tetrachloride. The weight...

Embodiment 2

[0035] (1) Using a ceramic sheet as a substrate, a pair of U-shaped gold electrodes with interdigital structure are printed on the upper surface of the ceramic sheet by screen printing. The gold electrode has a width of 200 μm and a thickness of 10 μm; on the lower surface of the ceramic sheet A layer of ruthenium dioxide is tiled as a heating layer, the thickness of the ruthenium dioxide is 30μm; a pair of strip-shaped gold electrodes are printed on the surface of the ruthenium dioxide layer, the width of the gold electrode is 500μm and the thickness is 10μm;

[0036] (2) Ultrasonic cleaning the upper surface of the ceramic sheet and the U-shaped gold electrode surface obtained in step (1) with ethanol and water, and drying;

[0037] (3) Prepare 5 mL of a nitrogen carbide aqueous solution with a concentration of 0.1 mg / mL, and then add 0.115 mg of tin tetrachloride, and ultrasonically disperse to make it fully mixed to obtain a composite solution of carbon, nitrogen and tetrachlori...

Embodiment 3

[0041] (1) Using the ceramic sheet as the substrate, a pair of U-shaped gold electrodes with interdigital structure are printed on the upper surface of the ceramic sheet by screen printing. The gold electrode has a width of 250 μm and a thickness of 20 μm; on the lower surface of the ceramic sheet A layer of ruthenium dioxide is tiled as a heating layer, the thickness of the ruthenium dioxide is 20μm; a pair of strip-shaped gold electrodes are printed on the surface of the ruthenium dioxide layer, the width of the gold electrode is 400μm and the thickness is 20μm;

[0042] (2) Ultrasonic cleaning the upper surface of the ceramic sheet and the U-shaped gold electrode surface obtained in step (1) with ethanol and water, and drying;

[0043] (3) Prepare 5 mL of aqueous solution of nitrogen carbide with a concentration of 0.3 mg / mL, then add 3.495 mg of tin tetrachloride, ultrasonically disperse to make it mix well, and prepare a composite solution of carbon, nitrogen and tetrachloride ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com