Fish feed and preparation method thereof

A fish feed and energy feed technology, applied in the field of feed processing, can solve problems such as insufficient feed utilization, unbalanced feed nutrition, and poor stability of fish feed, so as to improve digestibility and palatability, reduce utilization rate, and prevent illness and even death Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

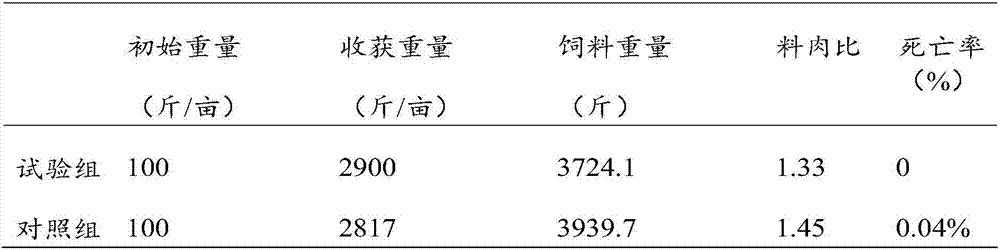

Image

Examples

preparation example Construction

[0032] A method for preparing the above-mentioned fish feed comprises mixing energy feed, protein feed, food-promoting plants, vitamins, minerals, carriers and binders.

[0033] Preferably, before mixing, energy feed, protein feed, food-promoting plants, vitamins, minerals, carriers and binders are pulverized and passed through a 30-60 mesh sieve to obtain under-sieve materials. Make the mixed raw materials more delicate.

[0034] Preferably, the puffing is extruded and puffed at a temperature of 120-135°C and a pressure of 1.5-2.5 MPa. Under the high-temperature treatment conditions, on the one hand, the starch is gelatinized, and the fat is stabilized and undegraded; and soften the fiber structure and cell wall, so that the utilization rate of various nutrients is improved. At the same time, the expansion process also destroys harmful substances such as myrosinase in rapeseed cake, trypsin in soybean meal and other harmful substances and growth inhibitory factors, thereby im...

Embodiment 1

[0038] A kind of fish feed with a particle size of 0.8 mm, which consists of 23.8 parts by weight of energy feed; 41 parts by weight of protein feed; 1.6 parts by weight of vitamins; 1.3 parts by weight of minerals; 2.4 parts by weight of food-promoting plants; 4.9 parts by weight 5.6 parts by weight of the carrier and 5.6 parts by weight of the binder are pulverized, mixed with the under-sieved material obtained after passing through a 30-60 mesh sieve, extruded and puffed at a temperature of 128°C and a pressure of 1.8MPa, and dried at 62°C 8h, granulation.

[0039] Among them, the energy feed includes 21 parts by weight of corn, 0.8 parts by weight of lard, and 2 parts by weight of soybean oil; the protein feed includes 27 parts by weight of soybean meal, 8 parts by weight of rapeseed cake, 2.5 parts of earthworm meal, and 3.5 parts by weight portion of tea leaves; the food-promoting plant is Houttuynia cordata. Minerals include chelated calcium, chelated phosphorus, chela...

Embodiment 2

[0041] A kind of fish feed that particle diameter is 3.5mm, and it is by the energy feed of 23 parts by weight; The protein feed of 38.2 parts by weight; The vitamin of 1.3 parts by weight; The mineral matter of 1.7 parts by weight; Parts by weight of the carrier and 5.7 parts by weight of the binder are pulverized, and the under-sieve material obtained after passing through a 60-mesh sieve is mixed, extruded and puffed at a temperature of 130°C and a pressure of 1.8MPa, and dried at 71°C for 6 hours , granulation.

[0042] Among them, the energy feed includes 20 parts by weight of corn, 0.7 parts by weight of lard, and 2.3 parts by weight of soybean oil; the protein feed includes 23 parts by weight of fermented soybean meal, 7 parts by weight of fermented rapeseed cake, and 3.7 parts by weight of earthworm powder , and 4.5 parts by weight of fermented tea leaves; the food-promoting plant is Houttuynia cordata. Minerals include chelated calcium, chelated phosphorus, chelated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com