Pressure sensitive material for high temperature and high pressure sensor and preparation method thereof

A sensitive material, high temperature and high pressure technology, applied in the direction of instruments, measuring devices, etc., can solve the problems of destroying the mechanical strength of materials, the inability to maintain the electrical conductivity of composite materials, and the destruction of conductive networks, so as to enhance interface interaction and benefit pressure-sensitive properties , the effect of effectively transmitting the force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3、7-9、16-18、21、24-28

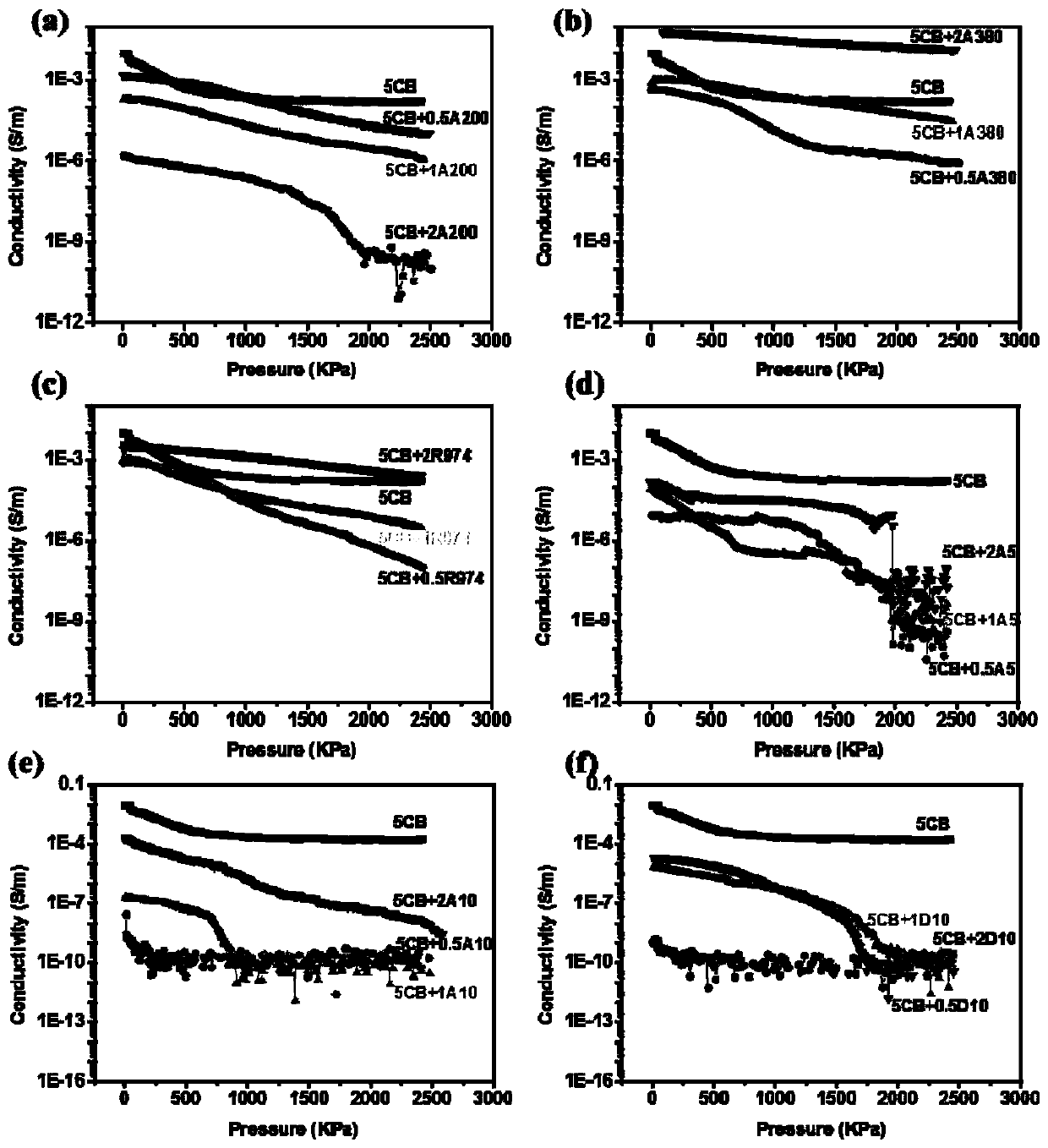

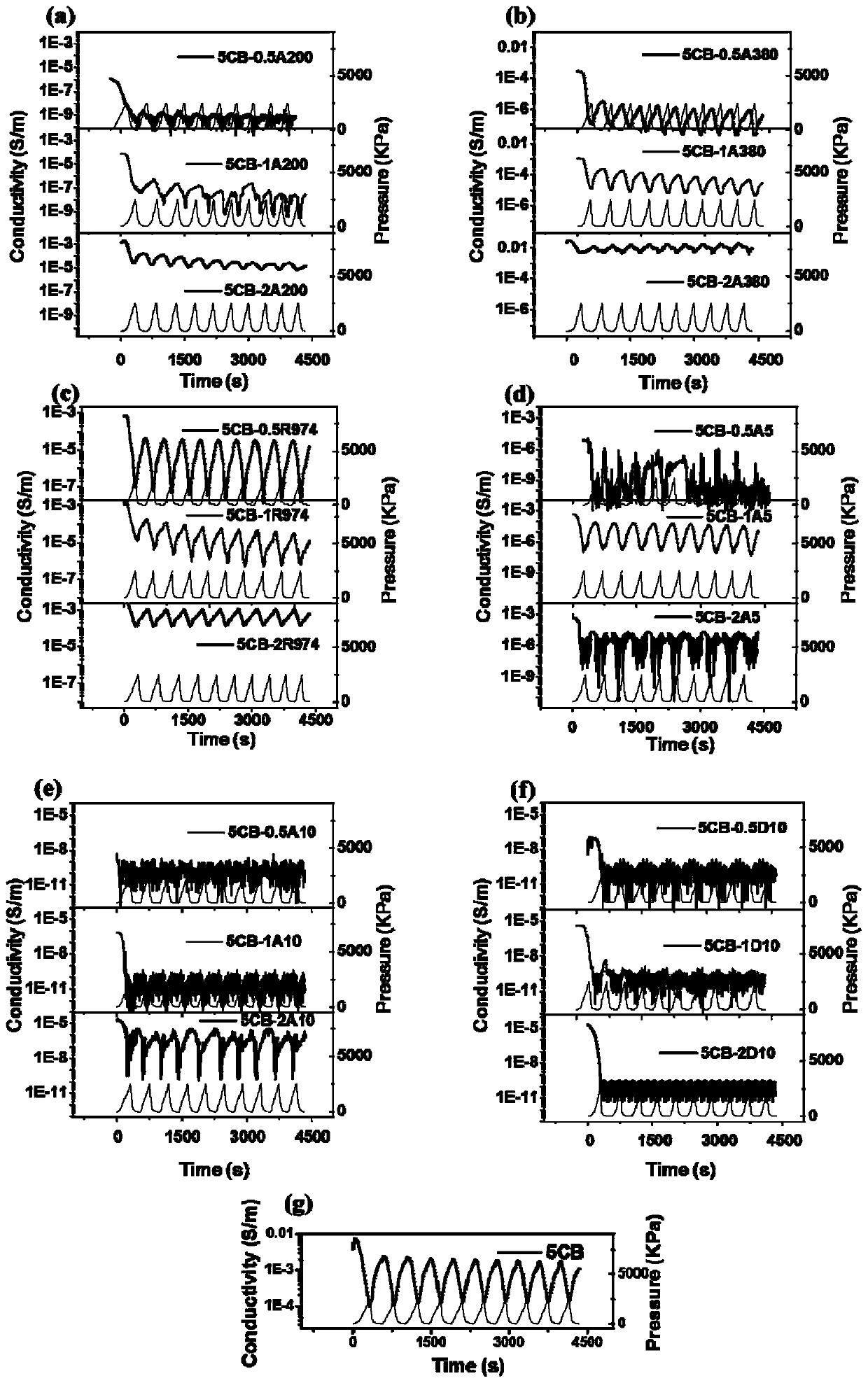

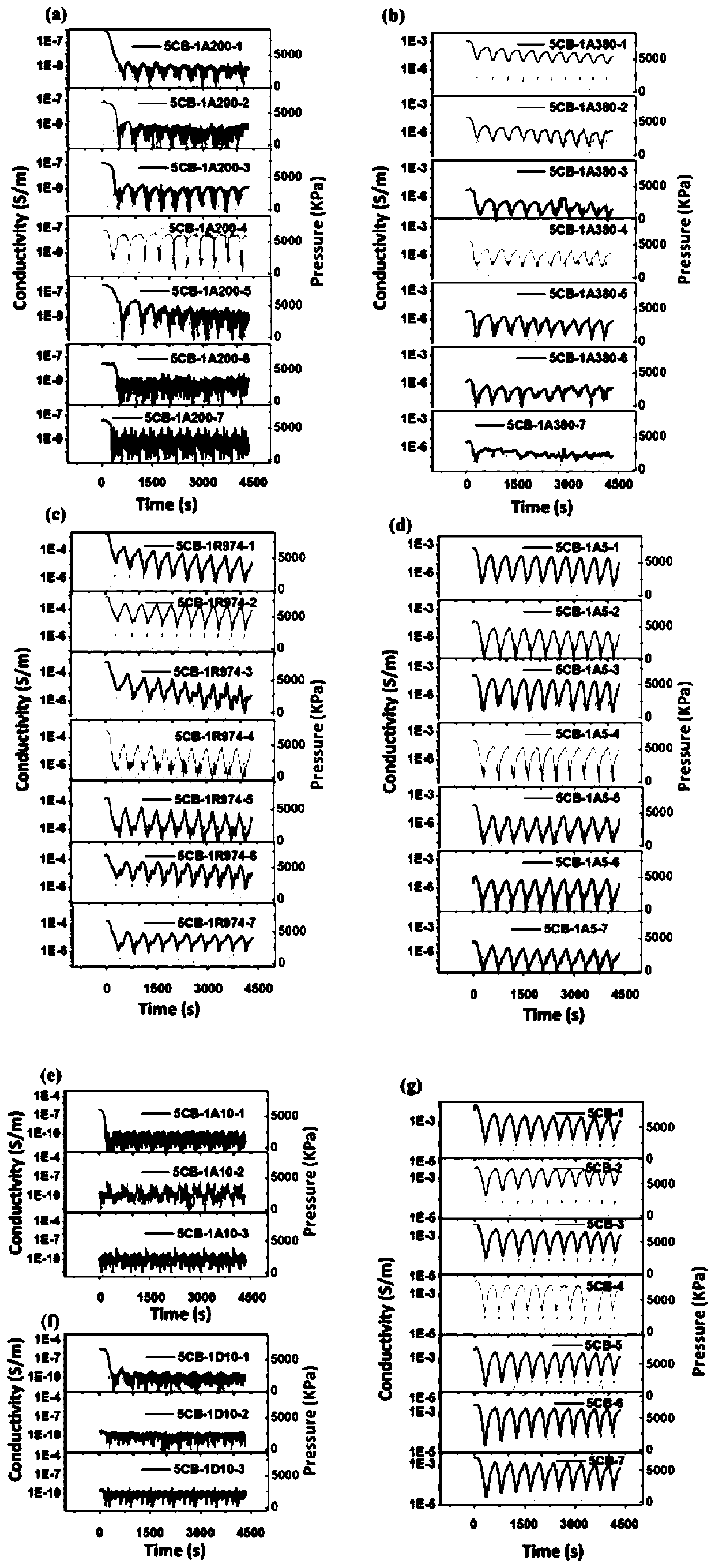

[0061] The raw materials and proportioning ratios used in Examples 1-3, 7-9, 16-18, 21, 24-28 are shown in Table 1. The process of preparing pressure-sensitive materials using the raw materials in Table 1 is as follows:

[0062] At normal temperature and pressure, add the weighed conductive carbon black and silicon dioxide or silicon dioxide with a core-shell structure into a non-polar organic solvent, and then undergo ultrasonic dispersion for 30 minutes and stirring for 30 minutes to obtain the first black color. Mixed solution; then add silicone rubber to the obtained first black mixed solution, and then obtain the second black mixed solution through ultrasonic dispersion for 15 minutes and stirring for 4 hours; inject the second black mixed solution into the mold frame, and statically After standing for 40 hours, the second mixed liquid is solidified and formed to obtain the pressure-sensitive material.

Embodiment 4-6

[0064] The raw materials and proportioning ratios used in Examples 4-6 are shown in Table 1, and the process of preparing pressure-sensitive materials using the raw materials in Table 1 is as follows:

[0065] At normal temperature and pressure, add the weighed conductive carbon black Printex XE-2B and silicon dioxide A380 into petroleum ether, then undergo ultrasonic dispersion for 45 minutes and stirring for 60 minutes to obtain the first black mixed solution; Silicone rubber NS-085 was added to the obtained first black mixed solution, followed by ultrasonic dispersion for 15 minutes and stirring for 4 hours to obtain the second black mixed solution; the obtained second black mixed solution was injected into the mold frame and stood at 130°C After 2 hours, the second mixed liquid is solidified and shaped to obtain the pressure-sensitive material.

Embodiment 10-12

[0067] The raw materials and proportions used in Examples 10-12 are shown in Table 1, wherein the silicone rubber GMX-351D includes 95 parts of A component and 5 parts of B component. The process of preparing pressure-sensitive materials using the raw materials in Table 1 is as follows:

[0068] At normal temperature and pressure, add the weighed conductive carbon black Printex XE-2B and silicon dioxide A5 into n-hexane, then undergo ultrasonic dispersion for 30 minutes and stirring for 45 minutes to obtain the first black mixed solution; The rubber GMX-351DA component was added to the obtained first black mixed solution, and after 15 minutes of ultrasonic dispersion, the silicone rubber GMX-351DB component was added, and the second black mixed solution was obtained after 5 hours of stirring; the obtained second black mixed solution Inject into the mold frame, and then stand at room temperature for 24 hours and at 80° C. for 4 hours to solidify the second mixed solution to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com