Electrolyzing solution, method and application for micro-arc oxidation

A micro-arc oxidation and electrolyte technology, applied in anodizing and other directions, can solve the problems of film performance influence, assembly difficulty, influence on the dimensional accuracy of parts, etc., and achieve the effect of improving corrosion resistance and good density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This example takes LY12 aluminum alloy material as an example for micro-arc oxidation, and the size of the aluminum alloy is 25×50×2mm 3 .

[0039] In the electrolyte of this example, sodium hexametaphosphate is used as the phosphate, ferric ammonium oxalate is used as the iron-containing compound, and disodium edetate (i.e. Na 2 EDTA), the electrolyte preparation method is as follows: Weigh sodium hexametaphosphate, ferric ammonium oxalate and Na 2 EDTA, add it to distilled water and stir to dissolve. Make sodium hexametaphosphate final concentration be 15g / L, ferric ammonium oxalate final concentration be 5g / L, Na 2 The final concentration of EDTA is 5g / L. That is, the electrolyte solution of this example is obtained.

[0040] The micro-arc oxidation method in this example includes:

[0041] 1) Pretreatment: Grinding the aluminum alloy, removing burrs on the surface and corners of the alloy with sandpaper, removing foreign matter on the surface, and reducing the ...

Embodiment 2

[0049] In this example, the same LY12 aluminum alloy material as in Example 1 was used for micro-arc oxidation. The difference is that in the electrolyte of this example, the final concentration of phosphate sodium hexametaphosphate is 10g / L, and the iron-containing compound adopts ferric ammonium citrate with a final concentration of 5g / L, and the complexing agent Na 2 The final concentration of EDTA was 7g / L. In addition, in the micro-arc oxidation method, the current density of the constant current mode is 8A / dm 2 , frequency 200Hz, response time 15min. All the other are the same as the first embodiment.

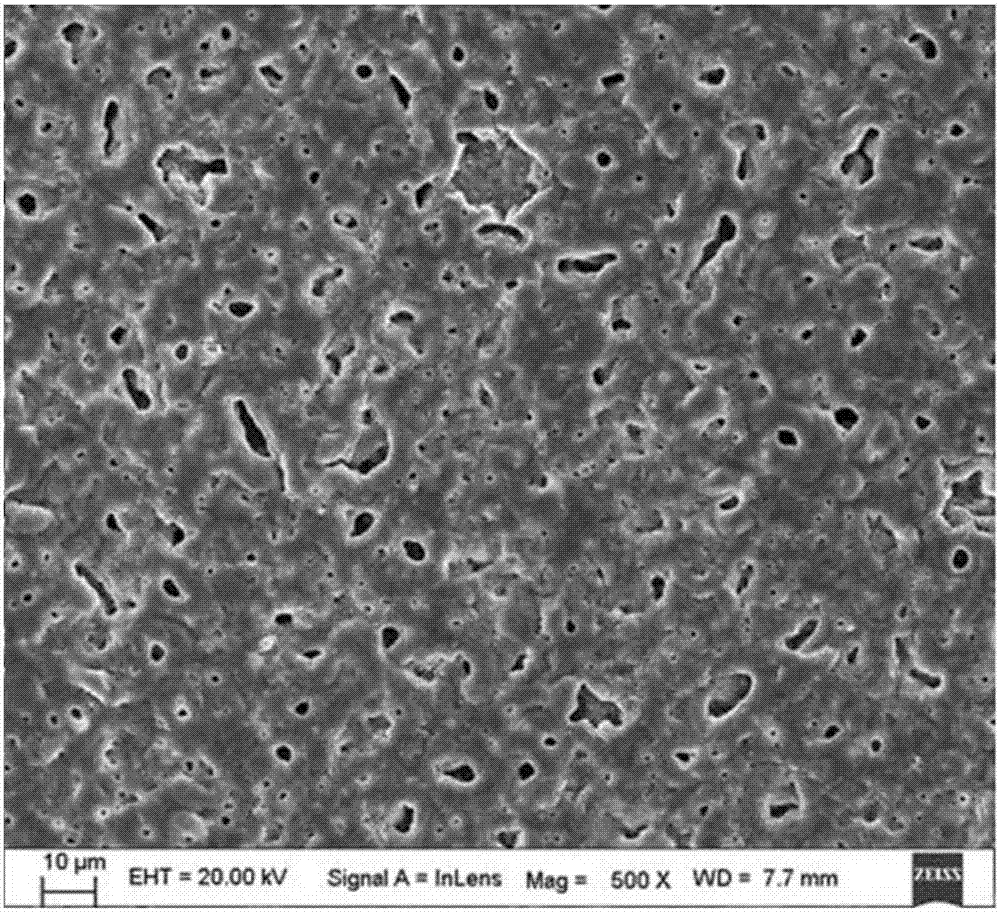

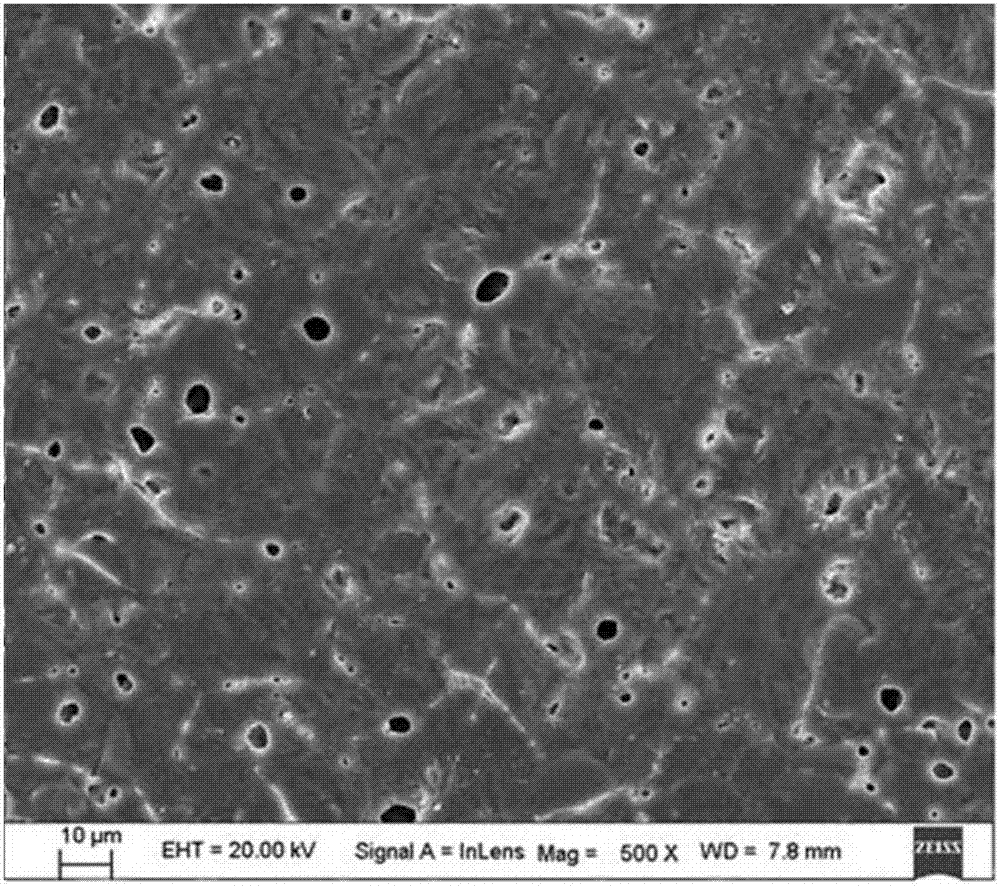

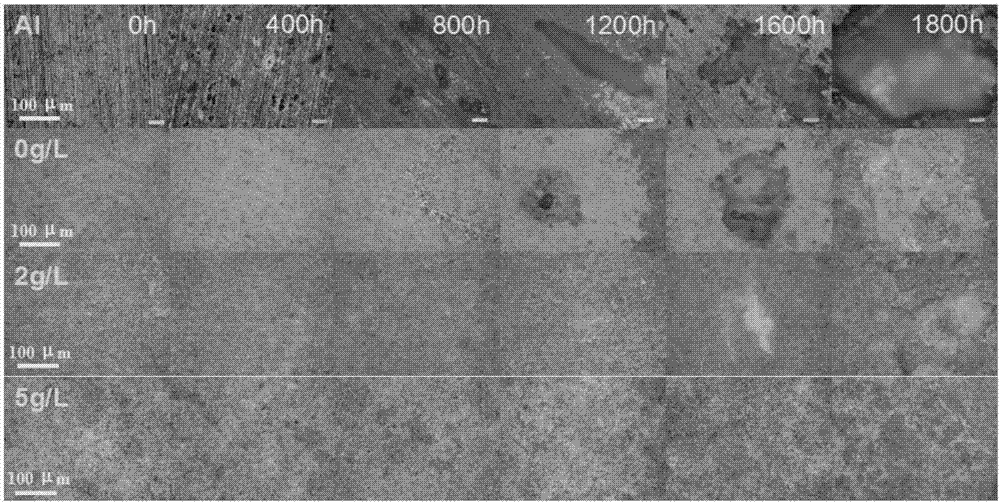

[0050] The micro-arc oxidation-treated aluminum alloy of this example was observed by scanning electron microscopy, and the results showed that a dense film was formed on the surface of the aluminum alloy with a film thickness of 25 μm. EDS found P and Fe elements in the film layer. Also use salt spray corrosion to test the corrosion resistance of the aluminum alloy t...

Embodiment 3

[0052] In this example, 6063 aluminum alloy material is used as an example for micro-arc oxidation. The size of the aluminum alloy is 25×50×2mm 3 . In the electrolyte of this example, the final concentration of phosphate sodium hexametaphosphate is 15g / L, what the iron-containing compound adopts is ferric nitrate whose final concentration is 4g / L, and what the complexing agent adopts is that the final concentration is 5mL / L Triethanolamine and Na at a final concentration of 5 g / L 2 EDTA. In addition, in the micro-arc oxidation method, the pulse power supply adopts a constant voltage mode, with a voltage of 450V, a frequency of 500Hz, and a response time of 10min. All the other are the same as the first embodiment.

[0053] The micro-arc oxidation-treated aluminum alloy of this example was observed by scanning electron microscopy, and the results showed that a dense film was formed on the surface of the aluminum alloy with a film thickness of 15 μm. EDS found P and Fe eleme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com