A method for making carbon quantum dots from tofu wastewater

A technology for carbon quantum dots and tofu wastewater, which is applied in the field of nanomaterials to achieve the effects of low cost, strong fluorescence and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

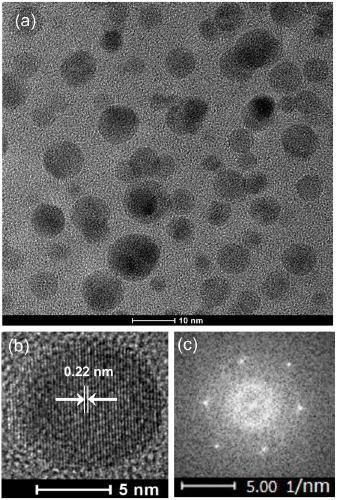

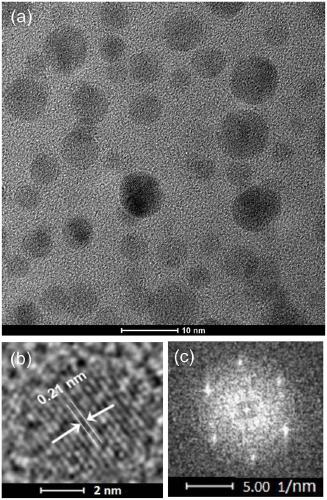

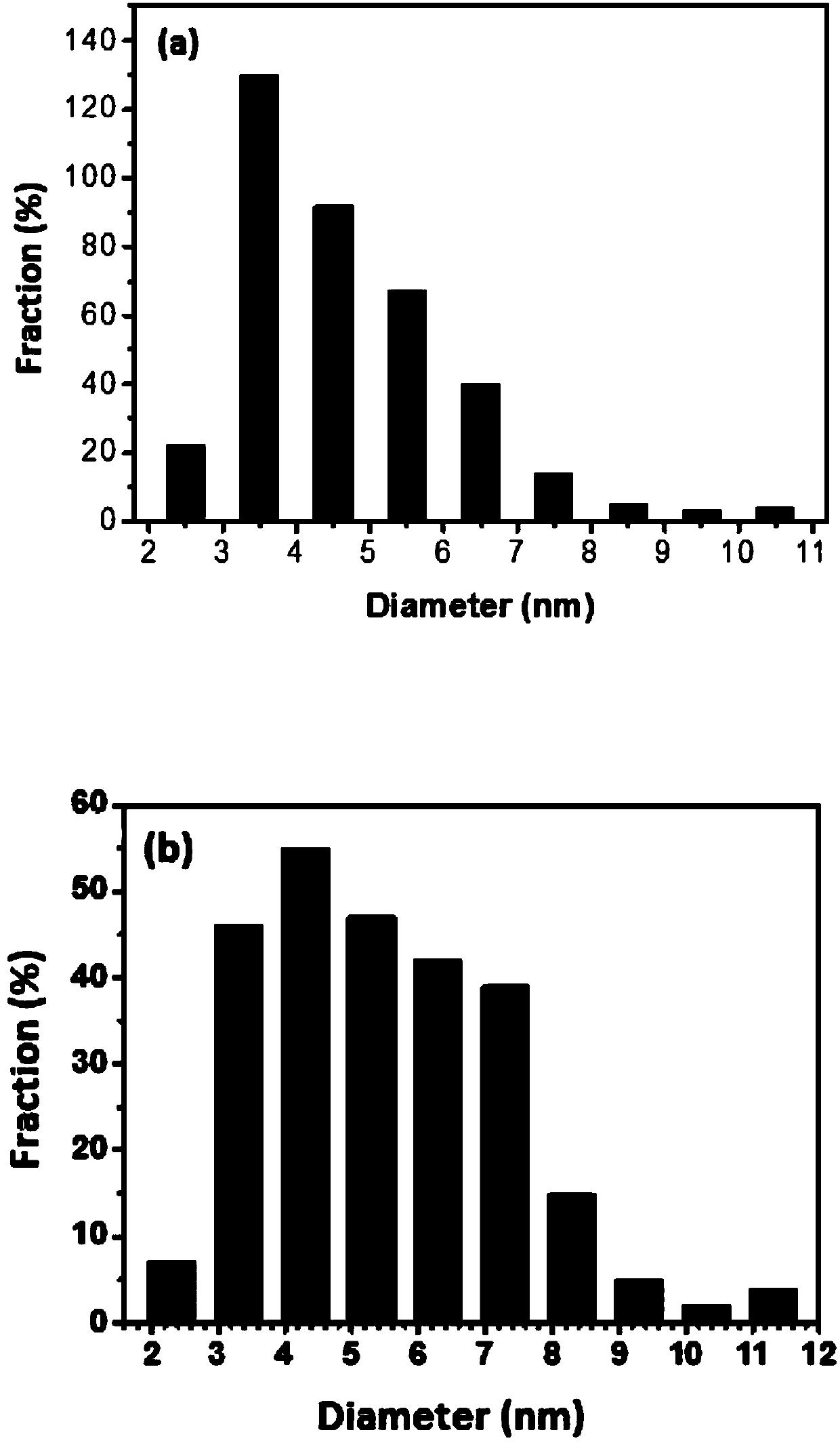

Image

Examples

Embodiment 1

[0025] Put the tofu yellow pulp water into 12 10 ml test tubes in turn and put them in a centrifuge with a rotating speed of 12000 r / min for 20 min, then take 500 ml of the centrifuged tofu yellow pulp water, and transfer the yellow pulp water solution Put it into a beaker with a volume of 500ml, and place it on a constant temperature heating platform. When the surface temperature of the heating platform rises to 280°C, heat the reaction at a constant temperature for 2 to 5 hours, and then take out the reactant after naturally cooling to room temperature. Add 50 ml of deionized water into the cooled beaker containing the reactants to form a mixed solution; then stir the mixed solution magnetically for 5 minutes, and then ultrasonically for 4 minutes after the stirring is completed, and wait for the mixed solution to stand evenly Finally, take the supernatant, repeat this step 2-3 times; then centrifuge the supernatant at 12000 r / min for 20 min, and take the supernatant again to...

Embodiment 2

[0028]Put the tofu yellow pulp water into 12 10 ml test tubes in turn and put them in a centrifuge with a rotation speed of 12000 r / min for 20 min, then take 300 ml of the centrifuged tofu yellow pulp water, and transfer the yellow pulp water solution Put it into a beaker with a volume of 500ml, and place it on a constant temperature heating platform. When the surface temperature of the heating platform rises to 230°C, heat and react at a constant temperature for 2 to 5 hours, and then cool naturally to room temperature before taking out the reactant. Add 150 ml of the currently configured sodium hydroxide solution at pH=12.35 to the cooled beaker containing the reactants to form a mixed solution; then stir the mixed solution magnetically for 5 minutes, and then sonicate for 4 minutes after the stirring is completed. After the mixture is allowed to stand evenly, take the supernatant, and repeat this step 2 to 3 times; then centrifuge the obtained supernatant at a speed of 12000...

Embodiment 3

[0034] In order to explore the regulation mechanism and method of the fluorescence wavelength of carbon quantum dots, the present invention puts the tofu yellow slurry water into 12 test tubes of 10 ml in turn and puts them into a centrifuge with a rotation speed of 12000 r / min for 20 min, and then takes 300 ml of centrifuged tofu yellow pulp water, transfer the yellow pulp aqueous solution to a beaker with a volume of 500 ml, and place it on a constant temperature heating platform. When the surface temperature of the heating platform rises to 230 ℃, the constant temperature heating reaction 2 After ~5 hours, take out the reactant after natural cooling to room temperature, then add 50 ml of sodium hydroxide solution of PH=12.35 to form a mixed solution in the beaker that is equipped with the reactant and cooled down; The mixture was magnetically stirred for 5 minutes, and then ultrasonicated for 4 minutes after the stirring was completed. After the mixture was allowed to stand ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com