Preparation method of iron-doped nickel based composite for electrochemical oxygen evolution

A composite material and iron-doped technology, which is applied in the field of preparation of catalytic materials, can solve the problems of high raw material cost, long production cycle, unfavorable industrial production, etc., and achieve the effect of high catalytic activity and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] First, the metal foam nickel substrate is cleaned with deionized water and ethanol respectively to remove dust and oil to obtain a clean nickel surface; secondly, prepare a KOH alkaline electrolyte with a KOH concentration of 300g / L; then, the cleaned nickel The electrode is immersed in the KOH electrolyte as the working electrode, and another metal iron electrode with the same area is added to the alkaline electrolyte as the counter electrode. Among them, the metal nickel electrode is used to provide the nickel element required for material preparation, and the metal iron electrode is used to provide the trace iron element required for material preparation. Electrochemical cyclic voltammetry (scanning rate: 100mV / s, scanning voltage window range of 0-2.5V) cyclically polarizes the nickel electrode for 12 hours, and a layer of iron-doped nickel base can be obtained on the surface of the nickel base. compound composites.

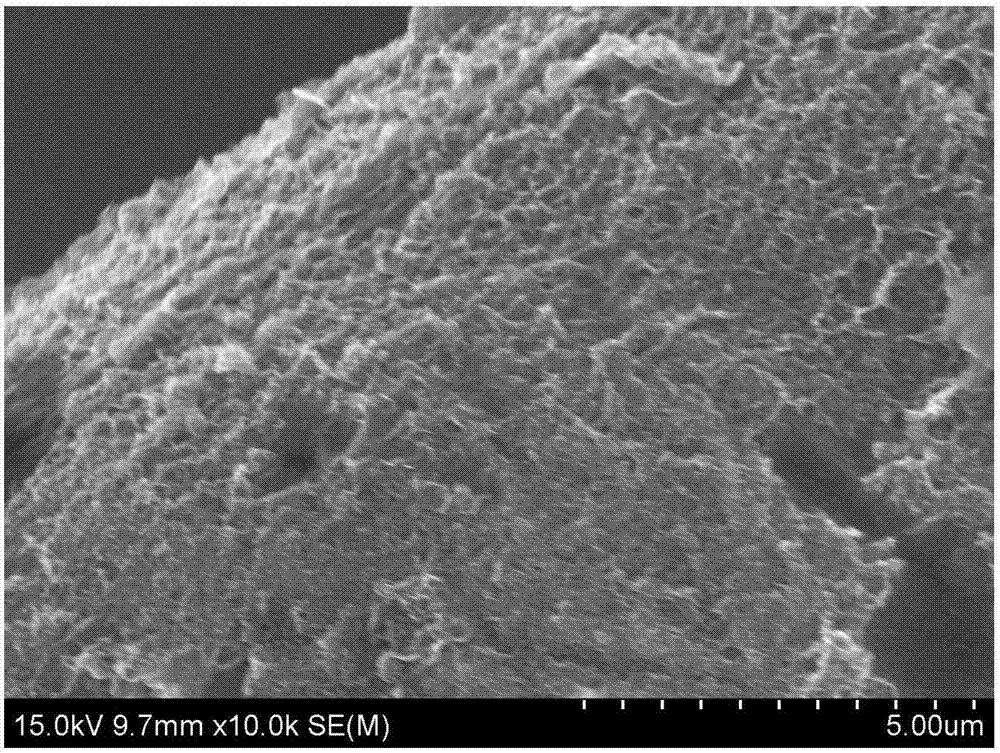

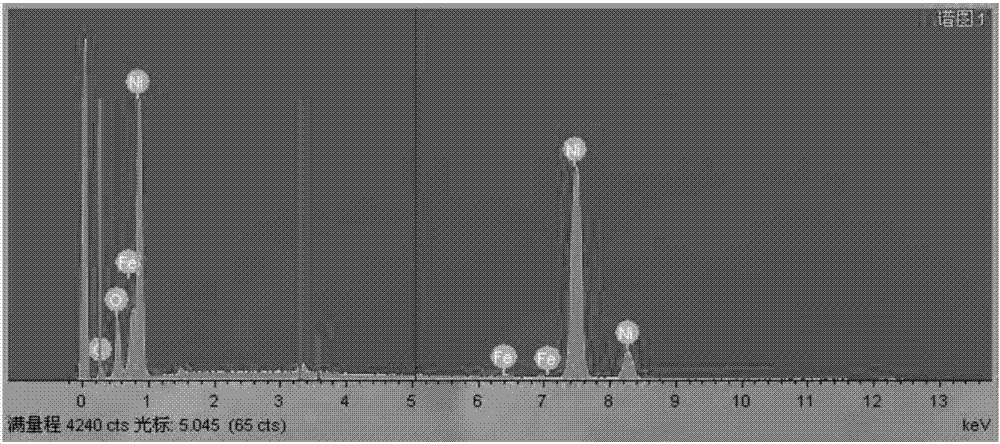

[0019] like figure 1 As shown, it can be seen ...

Embodiment 2

[0022] Firstly, the metal nickel substrate is cleaned with deionized water and ethanol respectively to remove dust and oil to obtain a clean nickel surface; secondly, NaOH alkaline electrolyte is prepared with a NaOH concentration of 250g / L; then, the cleaned nickel The electrode is immersed in the NaOH electrolyte as the working electrode, and another nickel sheet electrode with the same area is added to the alkaline electrolyte as the counter electrode, and 5g of iron powder is added to the electrolyte. Among them, the metal nickel electrode is used to provide The nickel element required for material preparation, and metal iron powder are used to provide the trace iron element required for material preparation. The nickel electrode is cyclically polarized for 24 hours by pulse voltage step technology (pulse width: 50s, high voltage 2.5V, low voltage 0.5V), and a layer of iron-doped nickel-based compound composite material can be obtained on the surface of the nickel substrate...

Embodiment 3

[0024] First, the metal foam nickel substrate was cleaned with deionized water and ethanol to remove dust and oil to obtain a clean nickel surface; secondly, LiOH alkaline electrolyte was prepared with a LiOH concentration of 100g / L; then, the cleaned nickel The electrode is immersed in the LiOH electrolyte as the working electrode. At the same time, another nickel foam electrode with the same area is added to the alkaline electrolyte as the counter electrode. Then, 10g of iron hydroxide powder is added to the electrolyte. Among them, the metal nickel electrode It is used to provide the nickel element required for material preparation, and the iron hydroxide powder is used to provide the trace iron element required for material preparation. A layer of iron-doped nickel-based compound composite material can be obtained on the surface of the nickel substrate by cyclically polarizing the nickel electrode for 6 hours by constant voltage step technology (high voltage 2.0V, low volta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com