Inverted organic solar cell using aluminum and sodium chloride as cathode buffer layer and preparation method thereof

A cathode buffer layer and solar cell technology, which is applied in the field of solar cells and achieves the effects of simple preparation process, abundant reserves and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

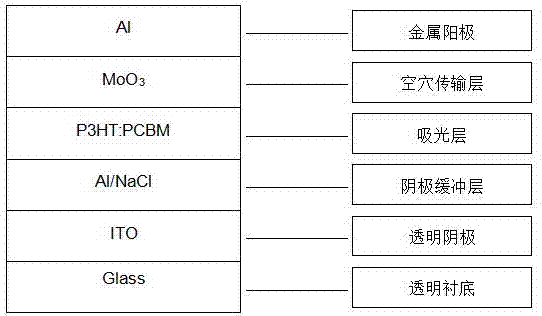

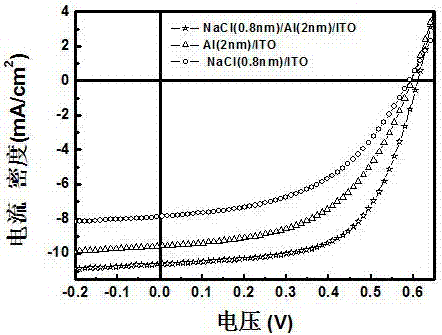

[0039]Sonicate the etched and cleaned ITO conductive glass twice for 15 minutes with the lotion solution, deionized water, acetone, and ethanol in sequence. P3HT and PC 61 BM was dissolved in dichlorobenzene solution at a mass ratio of 1:1 to prepare a solution with a concentration of 17 mg / ml. The mixed solution was uniformly stirred at a temperature of 60° C. for 12 hours before use. Dry the cleaned ITO conductive glass with nitrogen and UV for 15min. Use vacuum evaporation equipment to evaporate NaCl 0.8nm on ITO, the evaporation rate is 0.05-0.08 Å / s, and the evaporation pressure environment is less than 3×10 -4 Pa, forming the cathode buffer layer. Then transfer the evaporated film to the 2 Spin-coat the stirred P3HT:PCBM mixed solution onto the cathode buffer layer at a speed of 800rpm in a high-quality hand box for 60s, then dry it naturally at room temperature for 1 hour, and then anneal at 120°C Treat for 20 minutes to form a high-quality light-absorbing layer. ...

Embodiment 2

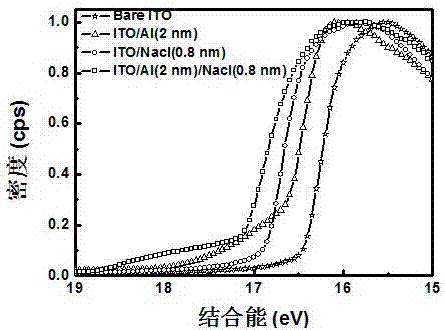

[0041] The same method as in Example 1 is used to prepare an inverted organic solar cell. The difference from Example 1 is that Al is deposited on the ITO conductive glass in this example with a thickness of 2nm to make an inverted organic solar cell with aluminum alone as the cathode buffer layer. Solar battery. At room temperature, the J-V curve of the device is as follows figure 2 As shown, the UPS energy spectrum of the Al-modified ITO surface is as follows image 3 As shown, the surface contact angle of ITO modified by Al and the AFM image of the active layer deposited on Al are shown in Figure 5 b and 5e are shown.

Embodiment 3

[0043] Sonicate the etched and cleaned ITO conductive glass twice for 15 minutes with the lotion solution, deionized water, acetone, and ethanol in sequence. P3HT and PC 61 BM was dissolved in dichlorobenzene solution at a mass ratio of 1:1 to prepare a solution with a concentration of 17 mg / ml. The mixed solution was uniformly stirred at a temperature of 60° C. for 12 hours before use. Dry the cleaned ITO conductive glass with nitrogen and UV for 15min. Use vacuum evaporation equipment to evaporate a 2nm Al layer on the cathode ITO, the evaporation rate is 0.5-1.0 Å / s, and the evaporation pressure environment is less than 3×10 -4 Pa, and then evaporate a NaCl layer with a thickness of 0.8nm on the Al layer, the evaporation rate is 0.05-0.08 Å / s, and the evaporation pressure environment is less than 3×10 -4 Pa, form the cathode buffer layer; then transfer the evaporated sheet to the 2 Spin-coat the stirred P3HT:PCBM mixed solution onto the cathode buffer layer at a speed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com