Flame-retardant PET and PC composite material and preparation method thereof

A composite material and flame retardant technology, which is used in the field of flame retardant PET and PC composite materials and their preparation, can solve the problem of the decline of mechanical properties of PET/PC composite materials, poor mechanical properties and heat resistance of products, and unfavorable large-scale industrial production. problems, to achieve the effect of reducing interface defects, good strength and rigidity, and improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

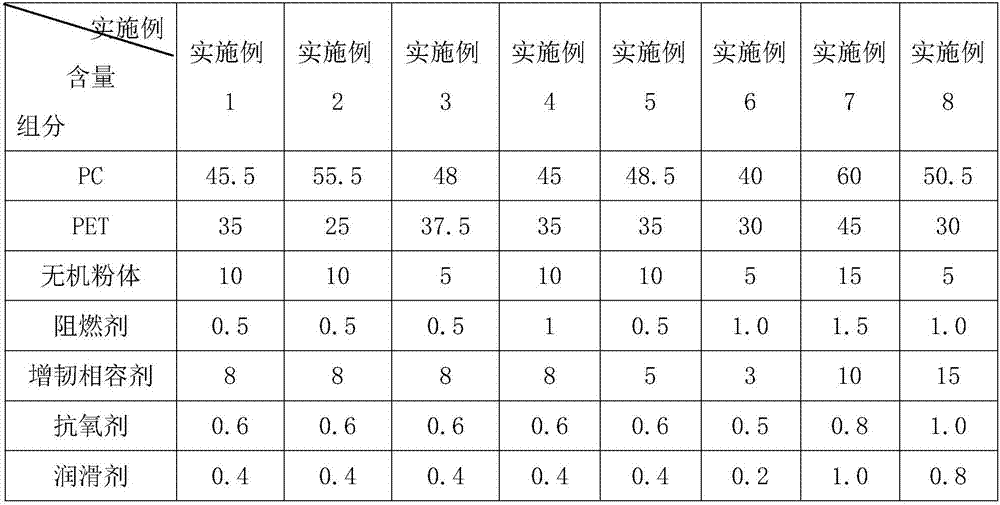

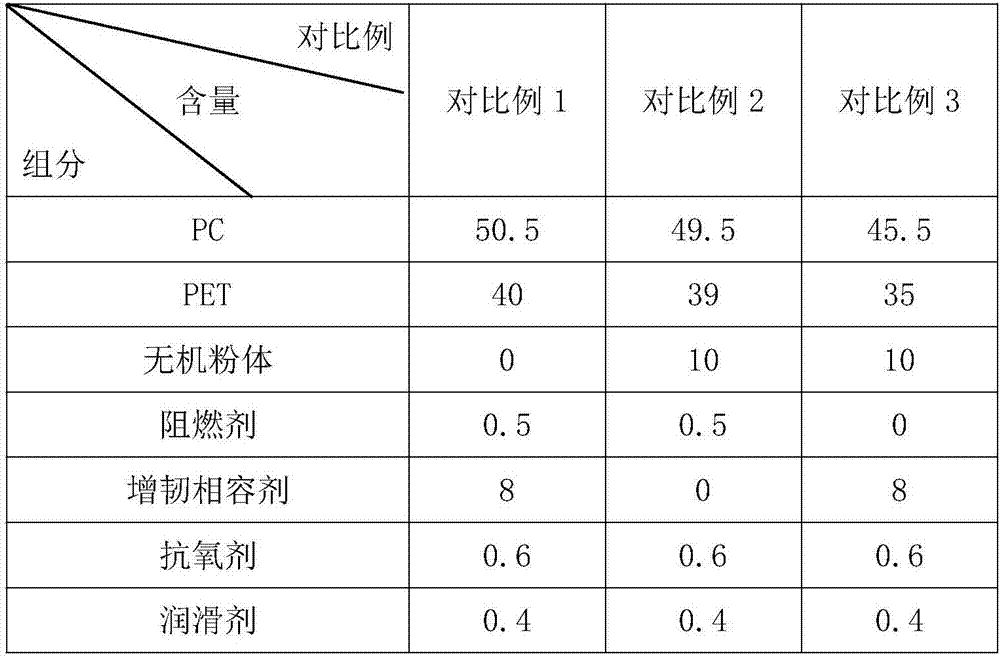

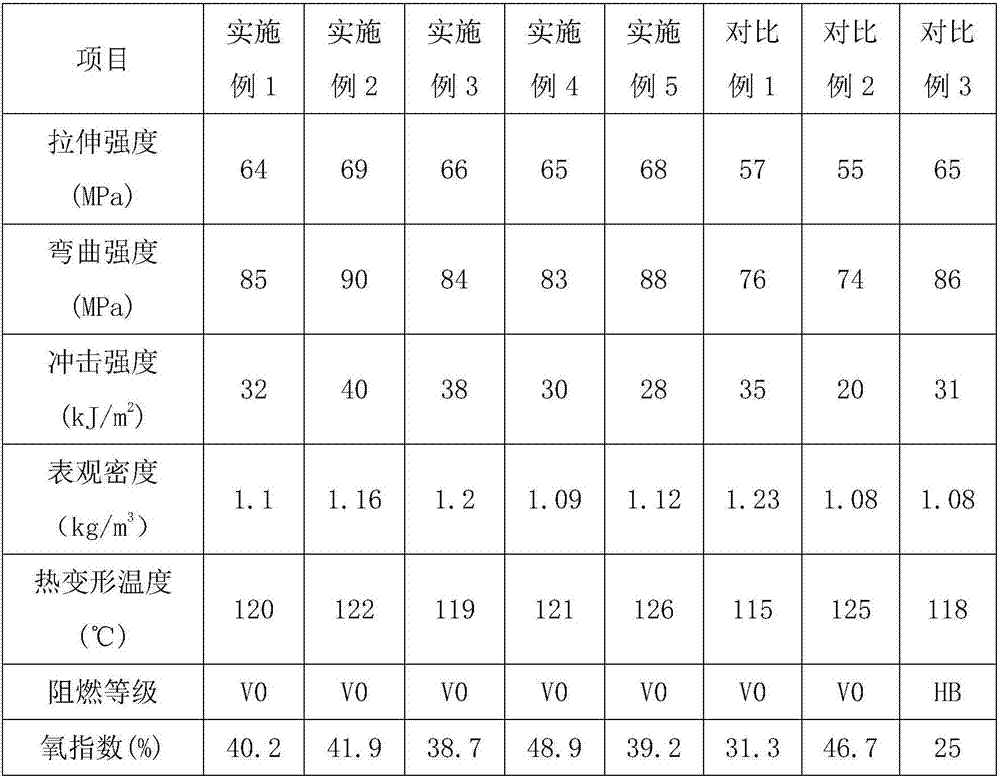

[0044] Embodiment 1-5: A flame-retardant PET and PC composite material, which is prepared by the following steps, and its components and contents are shown in Table 1:

[0045] S0: Treatment of inorganic powder: Dilute 1.5% of the total mass of inorganic powder with absolute ethanol in a water bath at 35-45°C for hydrolysis and dilution, the mass ratio of absolute ethanol to silane coupling agent 8:1, at 15-35°C, add the inorganic powder weighed in proportion while stirring the diluent, continue stirring for 5-10min after all the inorganic powder is added, and then dry at 80°C for more than 4h, Finally, place the dried powder in an airtight container for later use; the silane coupling agent is γ-(2,3-glycidoxy)propyltrimethoxysilane;

[0046] S1: Weigh each component according to the ratio in Table 1, wherein the inorganic powder has been treated in step S0 before use, and dry the weighed PC and PET at 120°C for at least 4 hours, and other components at 50- Dry at 80°C for 2 ho...

Embodiment 9

[0053] Embodiment 9: A composite material of flame-retardant PET and PC. The difference from Embodiment 2 is that the toughening compatibilizer is ethylene-methyl acrylate-glycidyl methacrylate copolymer.

Embodiment 10

[0054] Embodiment 10: A composite material of flame-retardant PET and PC. The difference from Embodiment 2 is that the flame retardant is 0.5 parts of octaphenylcyclotetrasiloxane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com