Polyvalent Alkyne Compound, Method For Producing The Same And Use Thereof

A compound and multi-component technology, applied in the fields of aldehyde/ketone condensation polymer adhesives, organic chemistry, electrical components, etc., can solve problems such as difficult to obtain heat-cured products with sufficient heat resistance, and achieve excellent heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

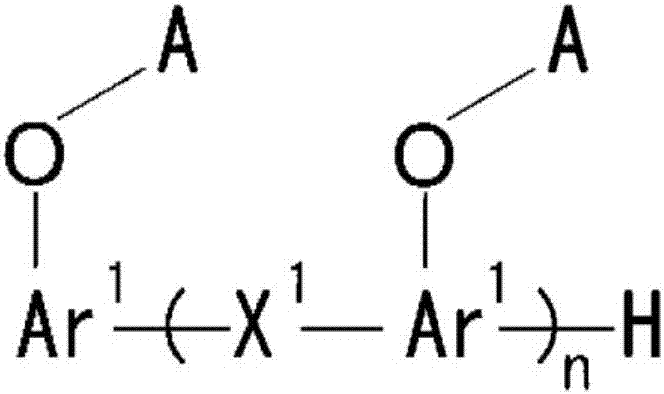

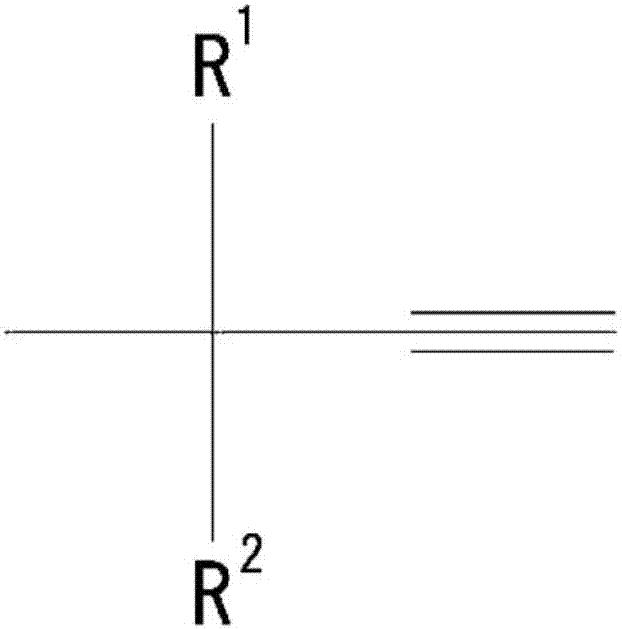

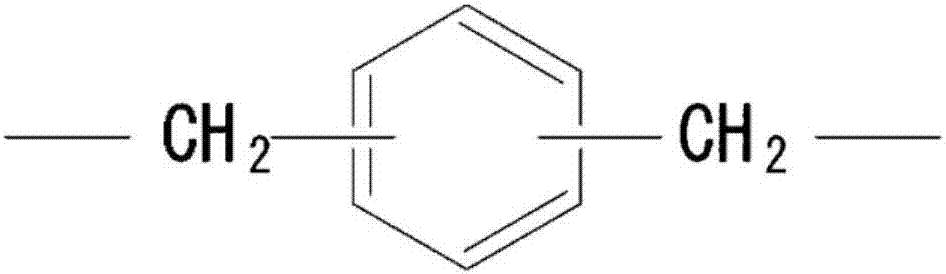

[0076] 79.1 g of a phenol aralkyl resin having a structure represented by formula (3) ("HE100C-30" manufactured by AIR WATER Corporation, hydroxyl equivalent 176 g / eq), 76.3 g of anhydrous potassium carbonate, 65.7 g of propargyl bromide, 460 g of acetone was charged into a 1 L autoclave, and kept at 90° C. for 15 hours while stirring. After cooling, the acetone solution was recovered by filtration, and the acetone was removed at 90° C. and 30 Torr to obtain 89.4 g of monomer A, namely X in formula (1). 1 Represented as a polyalkyne compound of formula (3).

[0077] The melt viscosity at 150° C. was measured with an ICI cone and plate viscometer (manufactured by MST Engineering Co., Ltd.), and it was 143 mPa·s. In addition, the hydroxyl equivalent calculated by the acetylation back titration method was 2962 g / eq, and the calculation result of the propargylation rate (the ratio of A in the formula (1) having the structure represented by the formula (2)) was 93%. That is, mono...

Embodiment 2

[0079] 94.6 g of phenol biphenyl aralkyl resin having a structure represented by formula (3) ("HE200C-10" manufactured by AIR WATER Co., Ltd., hydroxyl equivalent 206 g / eq), 76.3 g of anhydrous potassium carbonate, propargyl 65.7 g of bromide and 460 g of acetone were charged into a 1 L autoclave, and kept at 90° C. for 15 hours while stirring. After cooling, the acetone solution was recovered by filtration, and the acetone was removed at 90°C and 30 Torr to obtain 106.9 g of monomer B, namely X in formula (1). 1 Represented as a polyalkyne compound of formula (4).

[0080] The melt viscosity at 150° C. was measured by an ICI cone and plate viscometer, and the result was 33 mPa·s. In addition, the hydroxyl equivalent calculated by the acetylation back titration method was 3592 g / eq, and the calculation result of the propargylation ratio was 93%. That is, monomer B in which 93% of A in the polyalkyne compound represented by formula (1) has a structure represented by formula (...

Embodiment 3

[0082]Monomer A, which is a polyalkyne compound, and cobalt(III) acetylacetonate, which is a curing accelerator, were blended in the proportions shown in Table 1, and mixed and dispersed homogeneously to obtain a melt viscosity at 150°C (using ICI cone-plate viscosity A resin composition that is a thermosetting resin composition of 144 mPa·s. This was heated at 180° C. for 6 hours, and then heated at 230° C. for 6 hours to perform thermal curing to prepare a test sample as a thermosetting product of the thermosetting resin composition of the present invention. Using the test sample, the glass transition temperature and the 5% weight loss temperature were measured to evaluate the heat resistance of the thermosetting product. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl equivalent | aaaaa | aaaaa |

| Melt viscosity | aaaaa | aaaaa |

| Melt viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com