Preparation method of transparent paper

A technology of transparent paper and wood powder, which is applied in the directions of papermaking, papermaking, textiles and papermaking, etc., can solve the problems of low production efficiency of transparent paper, complicated nanofiber steps, time-consuming, labor-intensive and energy-consuming, etc. The effect is not high and the process is easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

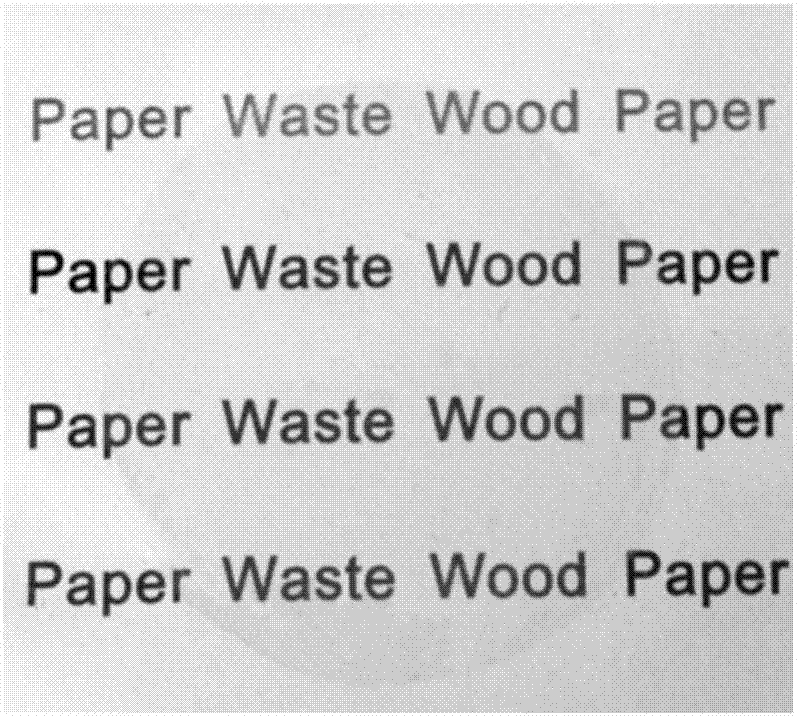

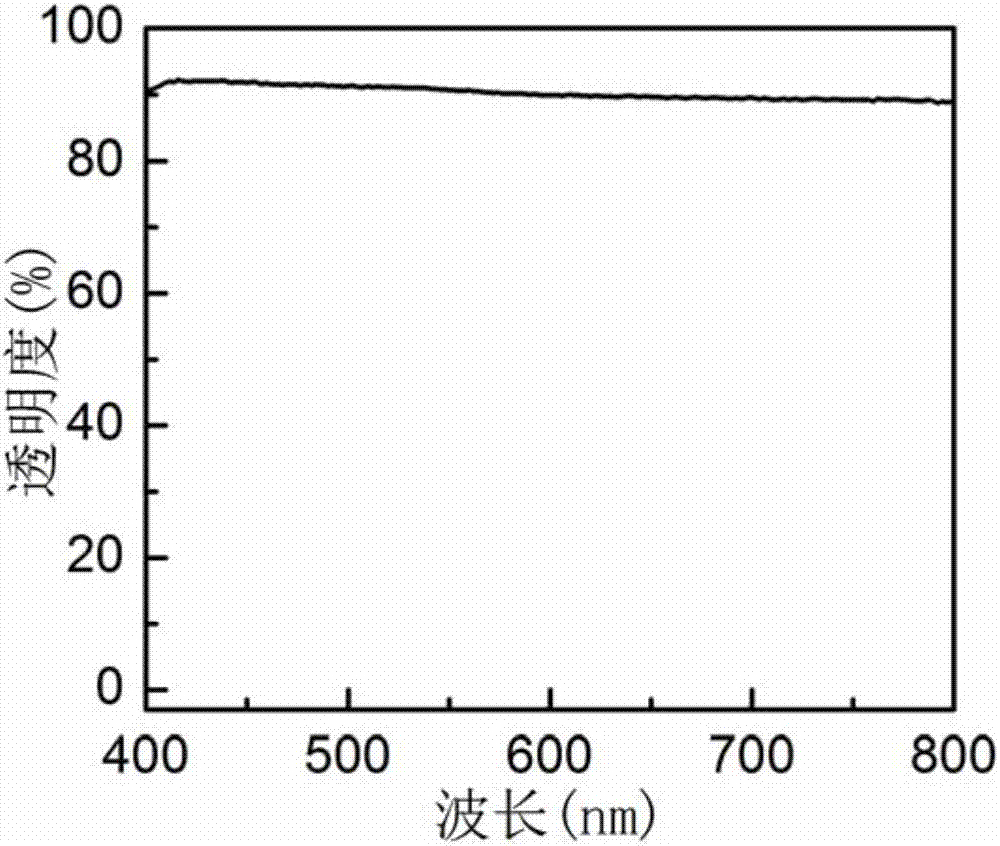

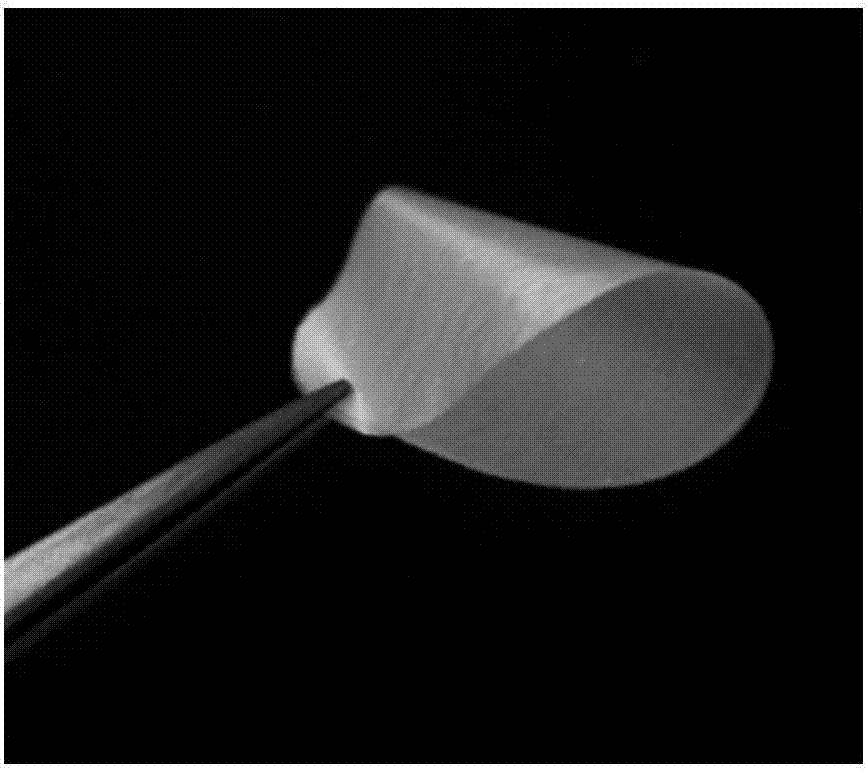

[0028] The basswood that removes bark is obtained basswood sawdust with sawdust grinder, it is mixed with the sodium hypochlorite solution that concentration is 15%, sawdust and sodium hypochlorite mass ratio are 1:10, at temperature is 50 degrees Celsius, react 10 minutes, react After the end, wash with water three times to remove residual sodium hypochlorite, take 5ml of slurry, and filter it with a suction filter to remove a large amount of water, then place the product in a press, and hold the pressure for 0.1 hour at a pressure of 0.1MPa. The obtained transparent paper material has a diameter of 40 mm, a thickness of 40 μm, and a transparency of 80%.

Embodiment 2

[0030] The basswood that removes bark is obtained basswood sawdust with sawdust grinder, and it is mixed with the sodium hypochlorite solution that concentration is 1%, and the mass ratio of sawdust and sodium hypochlorite is 1:10, and at temperature is 10 degrees Celsius, reacts 48 hours, reacts After finishing, wash with water three times, remove residual sodium hypochlorite, get 5ml slurry, and suction filtration with suction filtration device, remove a large amount of water, then product is placed in press, under pressure is 25MPa, keep pressure 2 hours, obtain The diameter of the transparent paper material is 40mm, the thickness is 40μm, and the transparency is 85%.

Embodiment 3

[0032] The basswood that will remove bark is obtained basswood wood powder with wood powder machine, and it is mixed with the sodium hypochlorite solution that concentration is 15%, and sawdust and sodium hypochlorite mass ratio are 1:10, and at temperature is 45 degrees Celsius, reacts 10 minutes, After the reaction finishes, wash with water three times to remove residual sodium hypochlorite, get 5ml of slurry, and filter with a suction filter to remove a large amount of water, then place the product in a press, and hold the pressure for 0.5 hour at a pressure of 2MPa. The obtained transparent paper material has a diameter of 40 mm, a thickness of 40 μm, and a transparency of 77%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com