Hollow hydroxyapatite microspheres with controllable pore size, preparation method and application thereof

A technology of hydroxyapatite and microspheres is applied in chemical instruments and methods, medical preparations with non-active ingredients, pharmaceutical formulations, etc. Effects of Biocompatibility and Degradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

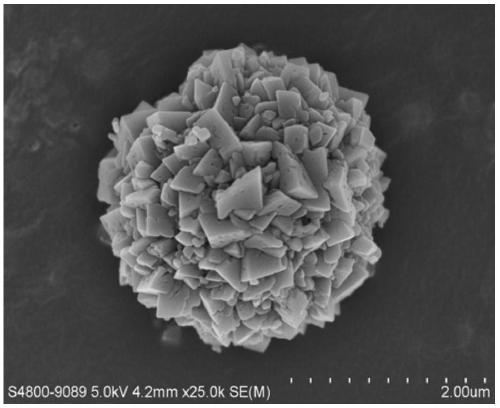

Image

Examples

Embodiment 1

[0061] The preparation of step A, calcium carbonate precursor:

[0062] Take 250 mL of calcium chloride solution with a concentration of 0.2 mol / L and mix it with 250 mL of sodium lauryl sulfate solution with a concentration of 1 mg / mL, add 250 mL of 0.2 mol / L sodium carbonate solution to the mixed solution after half an hour, and stir for 1.5 hour, filter to obtain the calcium carbonate precipitate, filter and wash the calcium carbonate precipitate 8 times with ultrapure water, then filter and wash the calcium carbonate precipitate 2 times with absolute ethanol, and finally dry the washed calcium carbonate precipitate at 120°C for 24 hours;

[0063] Step B, hydrothermal reaction:

[0064] Get the calcium carbonate precursor 1g that obtains in step A and mix with 0.2mol / L disodium hydrogen phosphate solution, control the mol ratio of calcium element and phosphorus element to be 1.67, be the ammoniacal liquor of 33% with mass percentage concentration Adjust the pH value to 10....

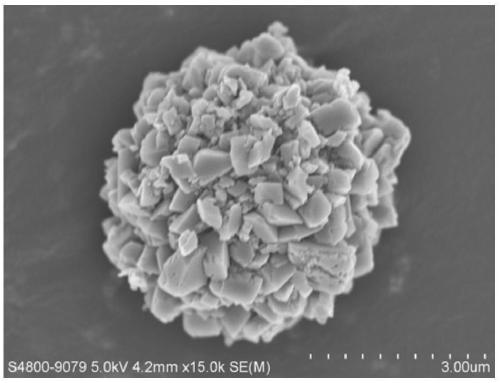

Embodiment 2

[0068] The preparation of step A, calcium carbonate precursor:

[0069] Take 250 mL of calcium chloride solution with a concentration of 0.2 mol / L and 250 mL of sodium lauryl sulfate solution with a concentration of 2.33 mg / mL and mix them. After half an hour, add 250 mL of 0.2 mol / L sodium carbonate solution to the mixed solution, stir After 1.5 hours, filter to get the calcium carbonate precipitate, filter and wash the calcium carbonate precipitate with ultrapure water 8 times, then filter and wash the calcium carbonate precipitate with absolute ethanol for 2 times, and finally dry the washed calcium carbonate precipitate at 120°C for 24 hours;

[0070] Step B, hydrothermal reaction:

[0071] Get the calcium carbonate precursor 1g that obtains in step A and mix with 0.2mol / L disodium hydrogen phosphate solution, control the mol ratio of calcium element and phosphorus element to be 1.67, be the ammoniacal liquor of 33% with mass percentage concentration Adjust the pH value t...

Embodiment 3

[0075] The preparation of step A, calcium carbonate precursor:

[0076] Take 250 mL of calcium chloride solution with a concentration of 0.2 mol / L and mix it with 250 mL of sodium lauryl sulfate solution with a concentration of 4.66 mg / mL, add 250 mL of 0.2 mol / L sodium carbonate solution to the mixed solution after half an hour, and stir After 1.5 hours, filter to get the calcium carbonate precipitate, filter and wash the calcium carbonate precipitate with ultrapure water 8 times, then filter and wash the calcium carbonate precipitate with absolute ethanol for 2 times, and finally dry the washed calcium carbonate precipitate at 120°C for 24 hours;

[0077] Step B, hydrothermal reaction:

[0078] Get the calcium carbonate precursor 1g that obtains in step A and mix with 0.2mol / L disodium hydrogen phosphate solution, control the mol ratio of calcium element and phosphorus element to be 1.67, be the ammoniacal liquor of 33% with mass percentage concentration The pH value was ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com