A pH-responsive in-situ controlled-release titanium-based implant and its preparation method and application

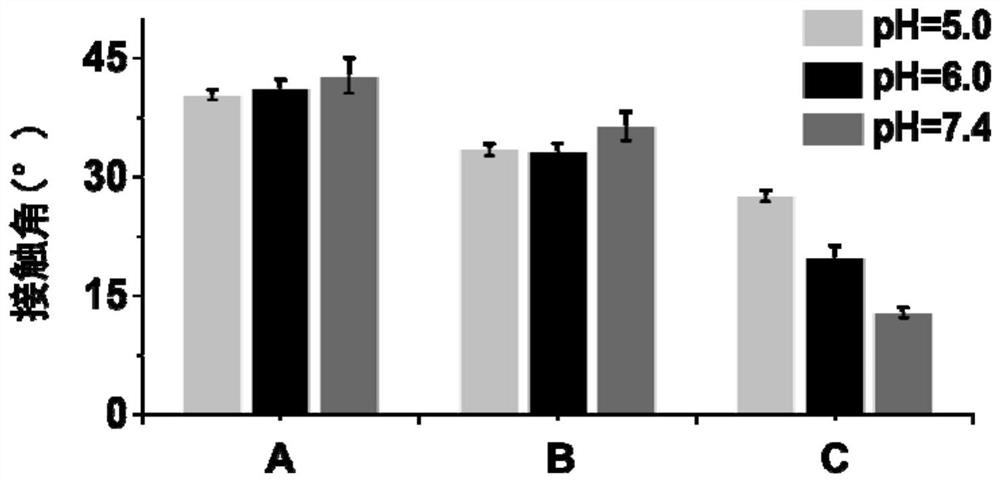

An implant, titanium-based technology, applied in the medical field, can solve problems such as low efficiency, high infection rate, bacterial infection, etc., and achieve the effect of reducing adverse effects, excellent antibacterial properties, and promoting bone repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] (1) Titanium-based implant was subjected to ultrasound washing by acetone, ethanol and deionized water, and then treated with hydrofluoric acid having a volume of 4% by concentration of 4%.

[0057] (2) Ammonium sulfate and ammonium fluoride were dissolved with deionized water to give 0.5 m ammonium sulfate and 1 wt.% Of the ammonium fluid mixture, and the solution pH to 4 was adjusted by sulfuric acid.

[0058] (3) The titanium-based implant after the hydrofluoric acid treatment in step (1) is an negative electrode, and the platinum sheet is a positive electrode, and the anodization is performed using an electrochemical workstation in constant voltage mode, wherein the voltage is 10V, anodic oxidation time. 0.5h, the electrode spacing is 2 cm.

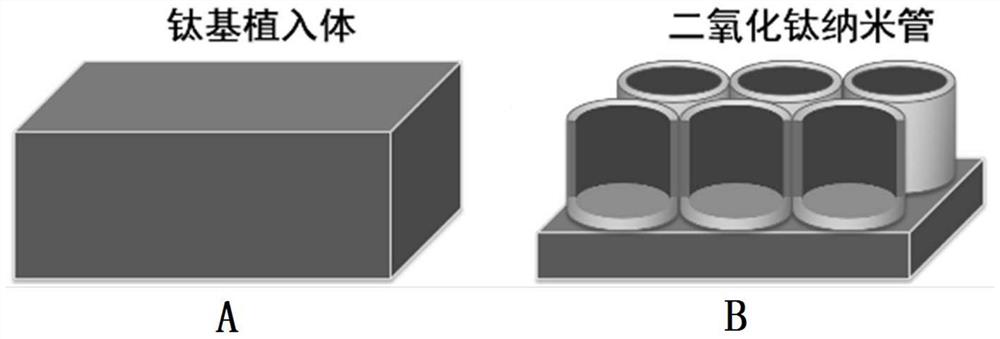

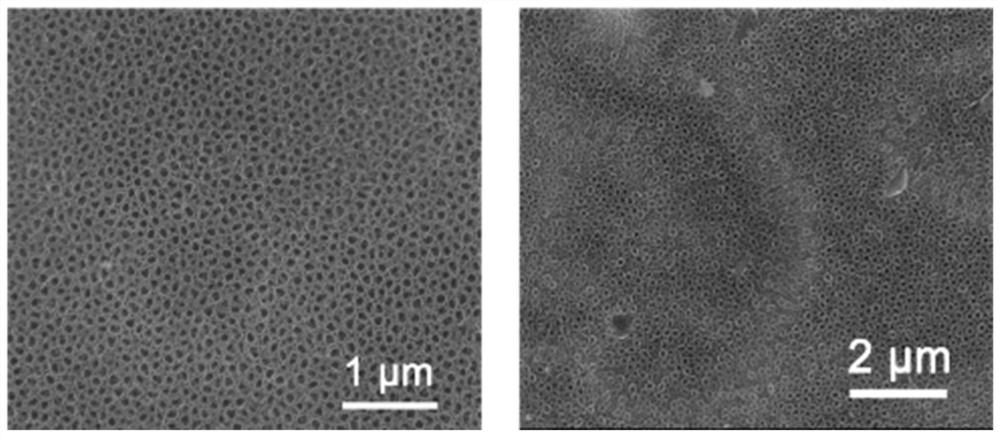

[0059] (4) The titanium-based implantation body having a titanium dioxide nanotube structure after the anodized surface was rinsed with deionized water, and dried at 60 ° C. figure 1 A schematic diagram of a titanium-based implant ...

Embodiment 2

[0067] (1) Titanium-based implant was subjected to ultrasound washing by acetone, ethanol and deionized water, and then treated with hydrofluoric acid having a volume of 4% by concentration of 4%.

[0068] (2) Ammonium ammonium sulfate and ammonium fluoride were dissolved with deionized water to give 0.5 m ammonium sulfate and 3 wt.% Of the ammonium fluid mixture, and the solution pH to 5 was adjusted by sulfuric acid.

[0069] (3) The titanium-based implant after the hydrofluoric acid treatment in step (1) is an negative electrode, and the platinum sheet is a positive electrode, and the anodization of the electrochemical workstation in constant pressure mode, wherein the voltage is 30V, anodation time 0.5h, the electrode spacing is 5 cm.

[0070] (4) The titanium-based implantation body having a titanium dioxide nanotube structure after the anodized surface was rinsed with deionized water, and dried at 60 ° C.

[0071] (5) Dissolve dicamine in Tris / HCl buffer solution (pH = 6.8...

Embodiment 3

[0078] (1) Titanium-based implant was subjected to ultrasound washing by acetone, ethanol and deionized water, and then treated with hydrofluoric acid having a volume of 4% by concentration of 4%.

[0079] (2) Ammonium sulfate and ammonium fluoride were dissolved with deionized water to give 0.5 M ammonium sulfate and 5 wt.% Of ammonium fluid mixture, and the solutions pH to 6 were modulated with sulfuric acid.

[0080] (3) The titanium-based implant after the treatment of hydrofluoric acid in step (1) is an negative electrode, and the platinum sheet is a positive electrode, and the anodization is performed by an electrochemical workstation in constant pressure mode, wherein the voltage range is 50V, anodized The time is 0.5h, the electrode spacing is 8cm.

[0081] (4) The titanium-based implantation body having a titanium dioxide nanotube structure after the anodized surface was rinsed with deionized water, and dried at 60 ° C.

[0082] (5) Dissolve dicamine in Tris / HCl buffer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com