Sodium nitrite-gelatin microsphere and preparation method and application thereof

A technology of sodium nitrite and gelatin, which is applied in the direction of application, preservation of meat/fish with chemicals, preservation of meat/fish with coating protection layer, etc., to achieve the effect of stable properties, simple operation and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The embodiment of the present invention discloses a preparation method of sodium nitrite-gelatin microspheres, specifically comprising the following steps:

[0052] (1) Add gelatin to deionized water and stir until completely dissolved to obtain a gelatin solution with a mass concentration of 0.01-0.1g / mL; wherein, the gelatin includes type A gelatin or type B gelatin; and a water bath at 50-55°C is used during the stirring process Heating by means of heating, the stirring speed is 100-500r / min;

[0053] (2) Then sodium nitrite is added to the gelatin solution according to the mass ratio of 1: (5-15) to the gelatin, and the stirring is continued until it is completely dissolved to obtain a mixed solution; wherein the temperature during the stirring process is 15-30°C , the stirring speed is 100-500r / min;

[0054] (3) Add transglutaminase (TGase) with a volume of 1-5mL and an enzyme activity of 120U / mL into the above mixed solution, and then stir and react to obtain a c...

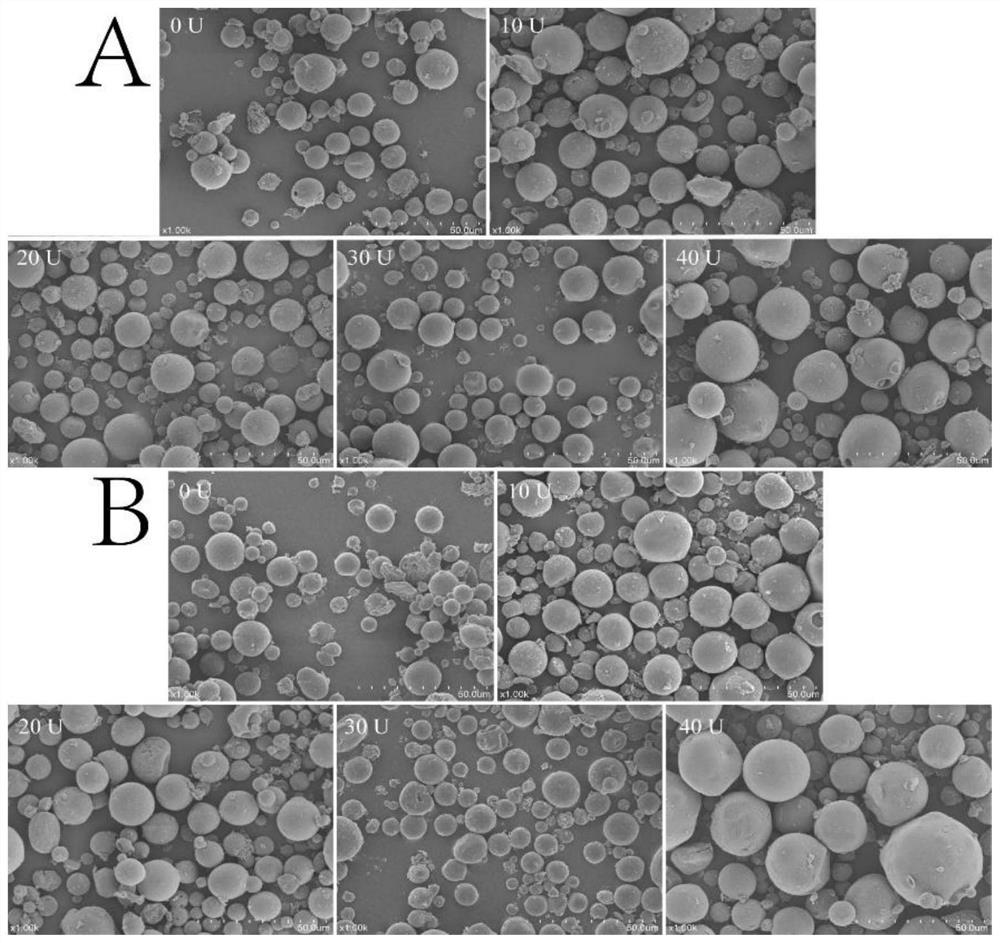

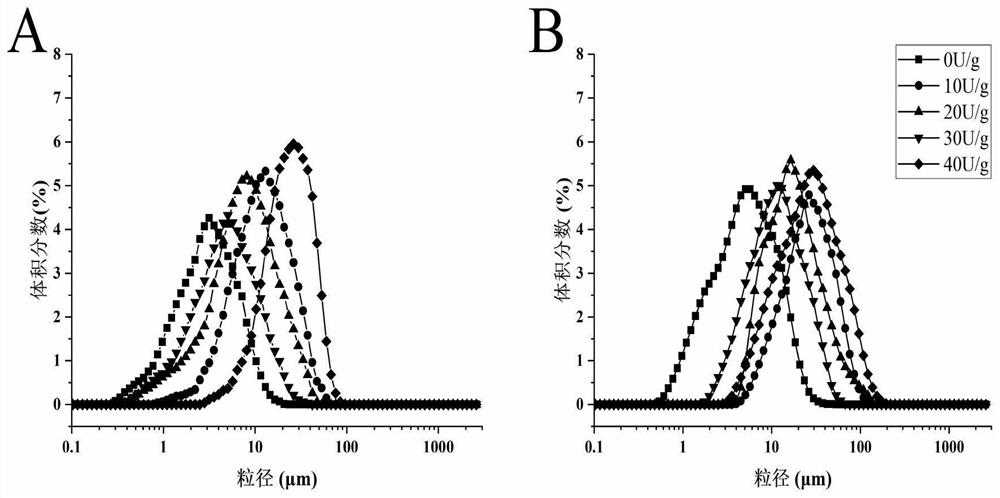

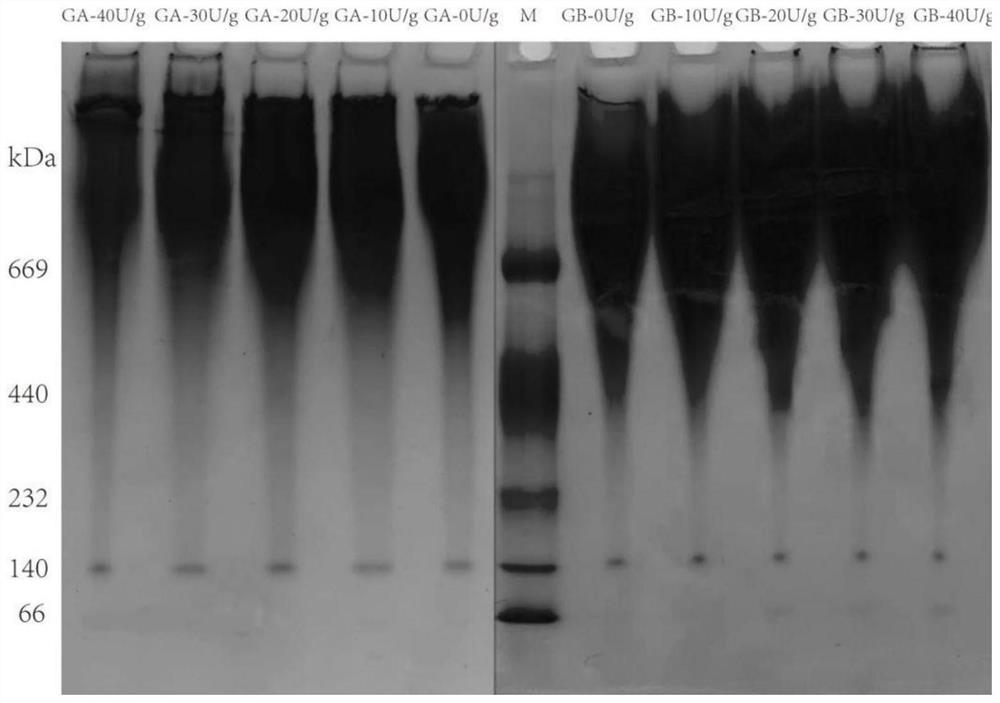

Embodiment 1~5

[0060] Embodiments 1 to 5 of the present invention disclose a preparation method of sodium nitrite-gelatin microspheres, specifically comprising the following steps:

[0061] (1) Add 1g of type A gelatin powder into 20mL of deionized water, and then stir it with a magnetic stirrer until completely dissolved in a water bath at 50-55°C to obtain a gelatin solution with a mass concentration of 0.05g / mL; 200r / min;

[0062] (2) Then 100mg of NaNO 2 Add it to the above gelatin solution, and stir until it is completely dissolved to obtain a mixed solution; the temperature during the stirring process is 25°C, and the stirring speed is 200r / min;

[0063] (3) Add transglutaminase (TGase) with an enzyme activity of 120U / mL to the above mixed solution according to the concentration of 0U / g, 10U / g, 20U / g, 30U / g, and 40U / g respectively, and then stir the reaction 2h obtains cross-linking solution;

[0064] (4) Add the emulsifier compounded by 2mL Span 80 and 1mL Tween 80 to 160mL corn oi...

Embodiment 6~10

[0068] Embodiments 6-10 of the present invention disclose a preparation method of sodium nitrite-gelatin microspheres, specifically comprising the following steps:

[0069] (1) Add 1g of B-type gelatin powder to 20mL of deionized water, and then stir it with a magnetic stirrer until it is completely dissolved in a water bath at 50-55°C to obtain a gelatin solution with a mass concentration of 0.05g / mL; 200r / min;

[0070] (2) Then 100mg of NaNO 2 Add it to the above gelatin solution, and stir until it is completely dissolved to obtain a mixed solution; the temperature during the stirring process is 25°C, and the stirring speed is 200r / min;

[0071] (3) Add transglutaminase (TGase) with an enzyme activity of 120U / mL to the above mixed solution according to the concentration of 0U / g, 10U / g, 20U / g, 30U / g, and 40U / g respectively, and then stir the reaction 2h obtains cross-linking solution;

[0072] (4) Add the emulsifier compounded by 2mL Span 80 and 1mL Tween 80 into 160mL cor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com