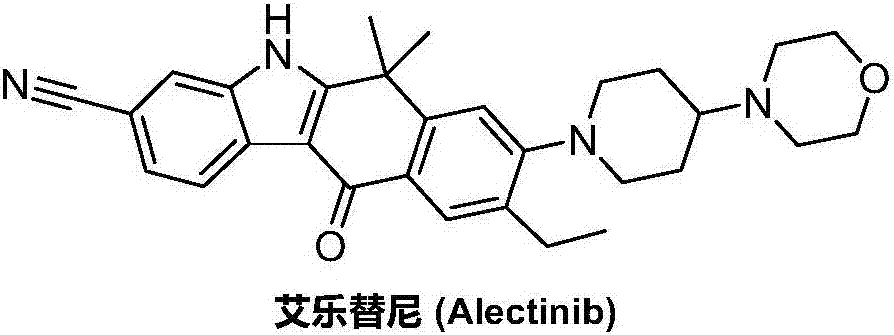

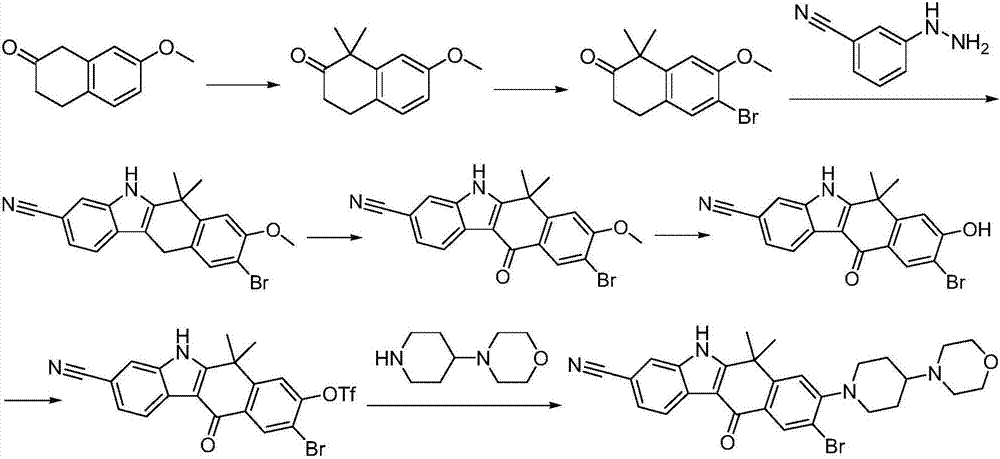

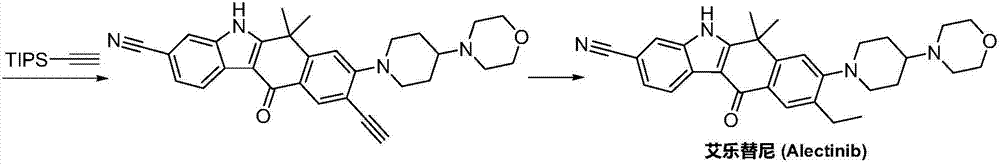

Preparation method of Alectinib intermediate

A technology for intermediates and tinib, which is applied in the field of preparation of alectinib intermediates, can solve the problems of short process flow, difficulty in obtaining, and low yield, and achieve the effects of reasonable technical scheme, simplified operation, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A) Preparation of ethyl 2-(4-ethyl-3-methoxyphenyl)-2-methylpropionate:

[0045] Dissolve ethyl 2-(4-ethyl-3-methoxyphenyl)acetate (12.0g, 54.0mmol) in methanol (250mL), slowly add sodium methoxide (7.3g, 135.1mmol), and cool to -5°C Left and right, methyl iodide (19.2g, 135.3mmol) was added dropwise, and the reaction mixture was stirred at 70°C for 4 hours. Dried over magnesium, concentrated to dryness by rotary evaporation, and recrystallized from methanol to obtain ethyl 2-(4-ethyl-3-methoxyphenyl)-2-methylpropionate, off-white solid (12.8g), yield 95%.

[0046] B) Preparation of ethyl 2-(4-ethyl-3-hydroxyphenyl)-2-methylpropionate:

[0047] Add ethyl 2-(4-ethyl-3-methoxyphenyl)-2-methylpropionate (12.5g, 49.9mmol) and 48% hydrobromic acid solution (101.0g, 599.1mmol) by mass percentage In the reaction flask, the reaction mixture was added to 100°C, refluxed and stirred for 24 hours, the reaction solution was lowered to 0-5°C, slowly added 50% sodium hydroxide sol...

Embodiment 2

[0057] A) Preparation of ethyl 2-(4-ethyl-3-methoxyphenyl)-2-methylpropionate:

[0058] Dissolve ethyl 2-(4-ethyl-3-methoxyphenyl)acetate (4.5g, 20.2mmol) in ethanol (120mL), add sodium ethoxide (4.1g, 60.2mmol) slowly, and cool to about 0°C , dropwise added iodomethane (8.6g, 60.6mmol), the reaction mixture was stirred and reacted at 60°C for 6 hours, the reaction solution was cooled to room temperature, adjusted to neutrality by adding dilute hydrochloric acid, concentrated to dryness by rotary evaporation, extracted with ethyl acetate, magnesium sulfate Dry, concentrate to dryness by rotary evaporation, and recrystallize from methanol to obtain ethyl 2-(4-ethyl-3-methoxyphenyl)-2-methylpropionate, off-white solid (4.5g), yield 89 %.

[0059] B) Preparation of ethyl 2-(4-ethyl-3-hydroxyphenyl)-2-methylpropionate:

[0060] 2-(4-Ethyl-3-methoxyphenyl)-2-methylpropionic acid ethyl ester (4.0g, 16.0mmol) and 48% concentration of hydrobromic acid aqueous solution (14.8g, 87.8mm...

Embodiment 3

[0070] A) Preparation of ethyl 2-(4-ethyl-3-methoxyphenyl)-2-methylpropionate:

[0071] 2-(4-Ethyl-3-methoxyphenyl)ethyl acetate (5.0g, 22.5mmol) was dissolved in isopropanol (120mL), slowly added sodium isopropoxide (3.7g, 45.1mmol), cooled To about 0°C, methyl iodide (6.4g, 45.1mmol) was added dropwise, the reaction mixture was stirred and reacted at 80°C for 2 hours, the reaction solution was cooled to room temperature, adjusted to neutrality by adding dilute hydrochloric acid, concentrated to dryness by rotary evaporation, and ethyl acetate was added Extracted, dried over magnesium sulfate, concentrated to dryness by rotary evaporation, and recrystallized from methanol to obtain ethyl 2-(4-ethyl-3-methoxyphenyl)-2-methylpropionate as off-white solid (4.7g) , yield 83%.

[0072] B) Preparation of ethyl 2-(4-ethyl-3-hydroxyphenyl)-2-methylpropionate:

[0073] 2-(4-Ethyl-3-methoxyphenyl)-2-methylpropionic acid ethyl ester (4.5g, 18.1mmol) and 48% concentration of hydrobromi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com