Biomass-and-city-solid-waste comprehensive utilization device and method

A biomass and urban technology, applied in the gasification process, petroleum industry, granular/powder fuel gasification, etc., can solve the problems of poor operation stability of the feeding system, limited comprehensive utilization and treatment capacity, and complex pollutant treatment. Achieve the effect of ensuring long-term stable operation, avoiding tar condensation to block pipelines, and controlling pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

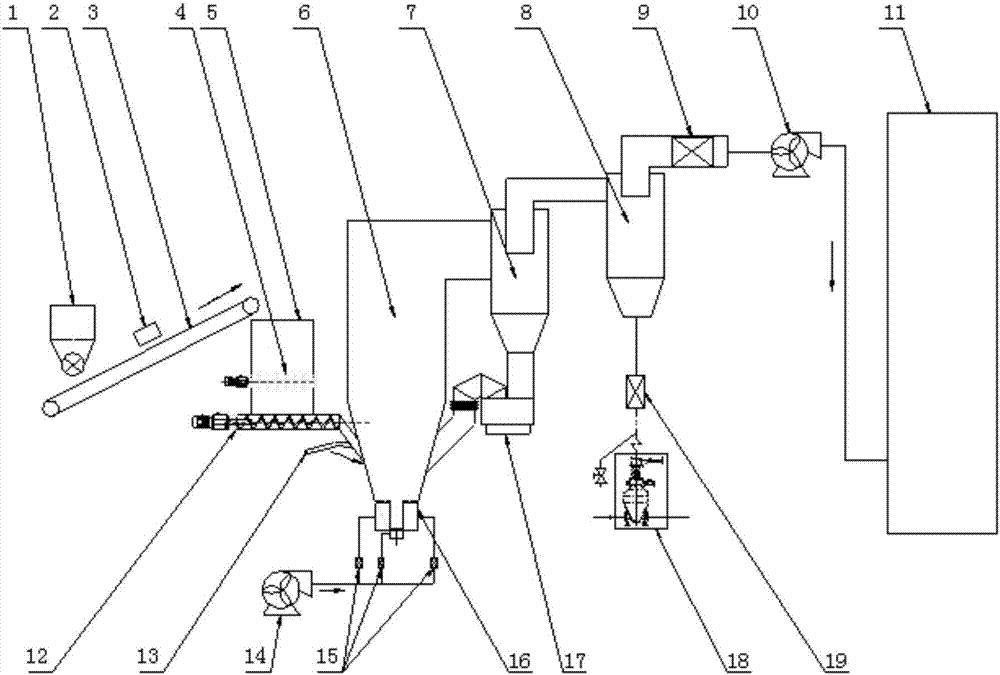

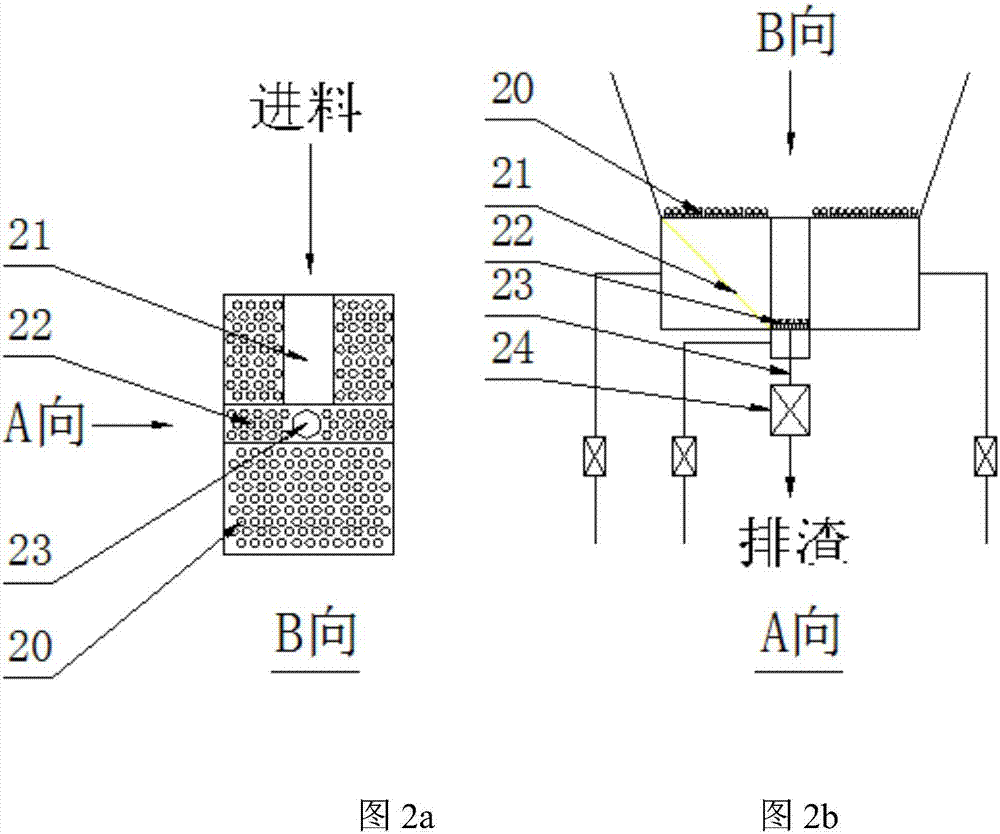

[0022] see figure 1 , a biomass and urban solid waste comprehensive utilization device provided by the present invention, comprising: a crusher 1 for crushing materials, a conveyor belt 3 is arranged below the discharge port of the crusher 1, and a conveyor belt 3 is provided above the conveyor belt The iron remover 2 is arranged at the position, and the end of the conveyor belt 3 is set at the entrance of the silo 5, and the inner middle of the silo 5 is provided with a pusher 4, and the bottom of the silo 5 is connected to a screw feeder 12, and the screw feeder 12 The outlet is connected to the gasification furnace 6, and the outlet of the screw feeder 12 is arranged with a sowing air 13; the bottom of the gasification furnace 6 is arranged with a fluidized separation device 16, and the fluidized separation device 16 is composed of an air distribution plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com