Recrystallization method of sucrose-6-acetate and applications thereof

An acetate and recrystallization technology, applied in chemical instruments and methods, sugar derivatives, sugar derivatives, etc., can solve problems such as increased environmental pressure, increased side reactions, and complicated treatment processes, and achieve the reduction of chlorinated reagents consumption, overcoming carbonization, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

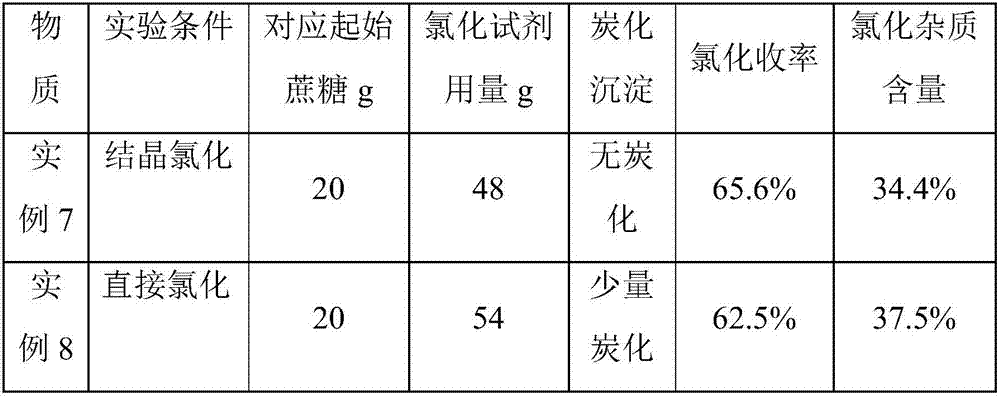

Examples

Embodiment 1

[0028] Add 500g of sucrose and 2L of DMF solution into a 5L four-neck flask, install a stirring paddle, a thermometer and a condenser tube with a water separator. Heat to 60°C, wait for the sucrose to dissolve, add 375g of dibutyltin oxide and 1.5L of cyclohexane, heat to 90-95°C to reflux and separate water, after 5 hours of reaction, cool to 5°C, add 157.5g of acetic anhydride dropwise After half an hour, it was warmed up to room temperature, continued to stir for 4 hours, added 150mL of water, stirred for half an hour and then distilled under reduced pressure to remove water, cyclohexane and most of the DMF to obtain 700g of the reaction mixture, which was analyzed by high performance liquid phase, the result See Table 1.

[0029] Weigh 20 g of the above mixture, heat it to 45°C, add 10 mL of acetonitrile and 5 mL of diethyl ether while stirring at a speed of 450 rpm, and after the concentrate is completely dissolved, cool down slowly and a white precipitate appears. Stand...

Embodiment 2

[0031] Add 500g of sucrose and 2L of DMF solution into a 5L four-neck flask, install a stirring paddle, a thermometer, and a condenser tube with a water separator. Heat to 60°C, wait for the sucrose to dissolve, add 375g of dibutyltin oxide and 1.5L of cyclohexane, heat to 90-95°C to reflux and separate water, after 5 hours of reaction, cool to 5°C, add 157.5g of acetic anhydride dropwise After half an hour, it was warmed up to room temperature, continued to stir for 4h, added 150mL of water, stirred for half an hour and then distilled under reduced pressure to remove water, cyclohexane and most of the DMF to obtain 700g of the reaction mixture.

[0032] Weigh 50 g of the above mixture, heat it to 40°C, add 15 mL of propionitrile and 7.5 mL of ether while stirring at a speed of 500 rpm, and after the concentrate is completely dissolved, cool down slowly and a white precipitate appears. Stand at -5°C to 0°C for 2h, filter, and dry to obtain 35.29g of white powdery crystals. Th...

Embodiment 3

[0034] Add 500g of sucrose and 2L of DMF solution into a 5L four-neck flask, install a stirring paddle, a thermometer, and a condenser tube with a water separator. Heat to 60°C, wait for the sucrose to dissolve, add 375g of dibutyltin oxide and 1.5L of cyclohexane, heat to 90-95°C to reflux and separate water, after 5 hours of reaction, cool to 5°C, add 157.5g of acetic anhydride dropwise After half an hour, it was warmed up to room temperature, continued to stir for 4h, added 150mL of water, stirred for half an hour and then distilled under reduced pressure to remove water, cyclohexane and most of the DMF to obtain 700g of the reaction mixture.

[0035] Weigh 50g of the above mixture, heat it to 45°C, add 40mL of butyronitrile and 8mL of diethyl ether while stirring at a speed of 500 rpm, and after the concentrate is completely dissolved, slowly cool down and white precipitate appears. Stand still at -5°C to 0°C for 1.5h, filter, and dry to obtain 35.66g of white powdery crys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com