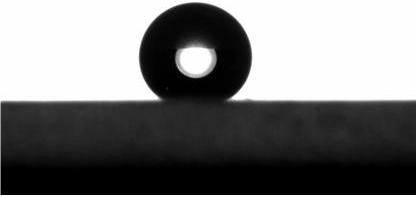

A kind of preparation method of bionic superhydrophobic composite organic pigment

A technology of organic pigments and composite pigments, applied in organic dyes, biocide-containing paints, antifouling/underwater coatings, etc., can solve the problems of superhydrophobic performance, poor lubrication effect, high cost, etc., to improve the application Value, low cost, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1 Preparation method of superhydrophobic composite methylene blue pigment

[0034] (1) Activation of sepiolite: add hydrochloric acid with a concentration of 1.0mol / L to sepiolite according to the solid-liquid ratio of 1:10 for activation, filter and wash with deionized water several times until neutral; dry at 105°C for 12 hours to obtain After activation of sepiolite, BET characterization shows that the specific surface area of activated sepiolite is 184m 2 / g;

[0035] (2) Dissolve 0.2g of methylene blue in 100ml of water, add 10g of sepiolite activated in step (1) under stirring conditions, stir and absorb at room temperature for 4h, filter and centrifuge, and dry at 80°C for 2 hours to obtain (sea pumice / methylene blue) composite pigment; (same type pigments include: methyl violet, methyl red, basic yellow, basic red, rhodamine B, etc.) (the composite pigment here is used as the product of comparative example 1 for follow-up comparison)

[0036] (3) Th...

Embodiment 2

[0048] Example 2 Preparation method of superhydrophobic composite basic yellow pigment

[0049] (1) Activation of sepiolite: add hydrochloric acid with a concentration of 1.0mol / L to sepiolite according to the solid-liquid ratio of 1:10 for activation, filter and wash with deionized water several times until neutral; dry at 105°C for 12 hours to obtain After activation of sepiolite, BET characterization shows that the specific surface area of activated sepiolite is 184m 2 / g;

[0050] (2) Dissolve 0.2g of Basic Yellow in 100ml of water, add 10g of sepiolite activated in step (1) under stirring conditions, stir and absorb at room temperature for 4h, filter and centrifuge, and dry at 80°C for 2 hours to obtain (Sepiolite / basic yellow) composite pigment; (same type of pigments include: methyl violet, methyl red, basic yellow, basic red, rhodamine B, etc.) products, for subsequent comparison)

[0051] (3) The ammonia solution is bubbled through the drying tower and passed thr...

Embodiment 3

[0057] (1) Activation of sepiolite: Add hydrochloric acid with a concentration of 2.0mol / L to sepiolite according to the solid-to-liquid ratio of 1:20 for activation, filter and wash with deionized water several times until neutral, and dry at 105°C for 12 hours to obtain Activated sepiolite;

[0058] (2) Dissolve 0.1g of rhodamine B in 100ml of water, add 10g of sepiolite activated in step (1) under stirring conditions, stir and absorb at room temperature for 6h, filter and centrifuge with suction, and dry at 60°C for 4 hours to obtain (Sepiolite / Rhodamine B) Composite Pigment; (Pigments of the same type include: Methyl Violet, Methyl Red, Basic Yellow, Basic Red, Rhodamine B, etc.)

[0059] (3) The ammonia solution is bubbled through the drying tower and passed through anhydrous ethanol to obtain a saturated ethanol solution of ammonia;

[0060] (4) Take 5g of the composite pigment obtained in step (2) and completely dissolve it in the ethanol saturated solution flask of 80...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com