Photovoltaic assembly

A photovoltaic module and reflective layer technology, applied in photovoltaic power generation, electrical components, semiconductor devices, etc., can solve the problems of short service life of TPT materials, short service life of photovoltaic modules, and inability to meet the needs of light transmission, achieving low cost, Effects of extending life and improving power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

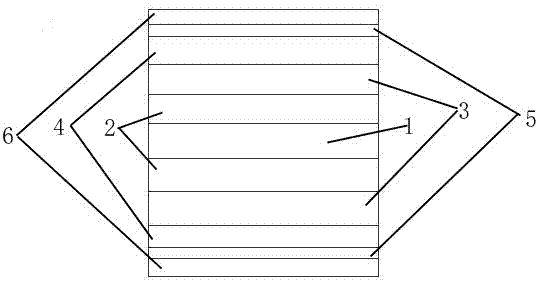

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

[0011] A photovoltaic module of the present invention comprises a silicon wafer cell 1, and a PET composite film 2 with a three-layer structure is packaged on the upper and lower surfaces of the silicon wafer cell, above the PET composite film on the upper surface and below the PET composite film on the lower surface A back plate 3 is provided, and a reflective layer 4 is provided above the back plate above the PET composite film on the upper surface and below the back plate below the PET composite film on the lower surface. Photovoltaic glass 5 is provided below the photovoltaic glass, and a radiation-proof metal film 6 is provided on the outer surface of the photovoltaic glass.

[0012] The PET composite film has a three-layer structure, which is formed by pasting and pressing the modified EVA / POE film and the corona-treated PET substrate film; the modified EVA / POE f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com