Alpha-alumina carrier of silver catalyst for olefin epoxidation, preparation and application thereof

A technology of alumina carrier and silver catalyst, which is applied in the direction of catalyst carrier, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc. Evenly distributed and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] According to some specific embodiments of the present invention, the preparation method of the α-alumina carrier involved in the second aspect of the present invention as in the first aspect of the present invention includes the following steps:

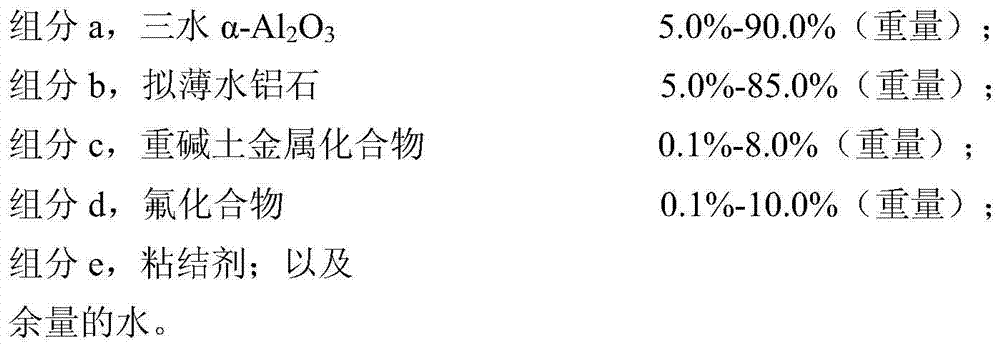

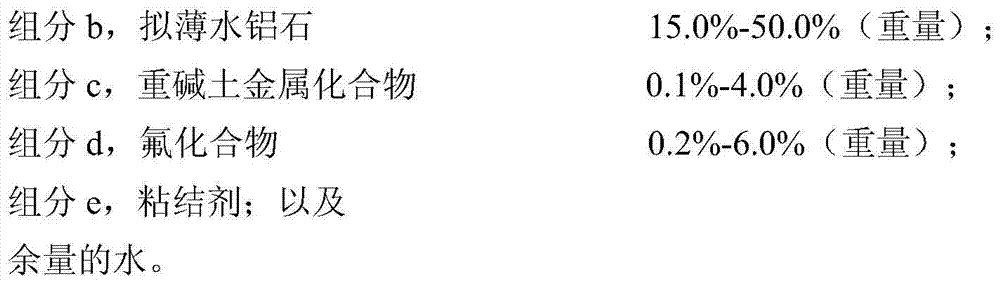

[0039] (1) Prepare a solid mixture with the following composition:

[0040] Component a, 5.0%-90.0% (weight) of alumina trihydrate based on the total weight of the solid mixture;

[0041] Component b, 5.0%-85.0% (weight) pseudo-boehmite of the total weight of the solid mixture;

[0042] Component c, 0.1%-8.0% (by weight) of heavy alkaline earth metal compounds of the total weight of the solid mixture;

[0043] Component d, 0.1%-10.0% (weight) of fluorine compound based on the total weight of the solid mixture;

[0044] (2) Adding component e binder and water to the solid mixture obtained in step (1) to prepare an α-alumina carrier precursor mixture;

[0045] (3) The α-alumina carrier precursor mixture obtained in step (2) is kneaded, shap...

Embodiment 1

[0084] (1) Preparation of carrier: Weigh 427.0g of gibbsite, 71.0g of diaspore, 102.0g of pseudo-boehmite, 10.0g of ammonium fluoride, and 4.0g of barium sulfate, put them in a mixer and mix them evenly. Transfer to the kneader, add dilute nitric acid (nitric acid: water = 1:3, weight ratio, the density of nitric acid is 1.07g / cm 3 ) Until it is kneaded into an extrudable paste, put the paste into an extruding machine and squeeze it into a five-hole column, and dry it at 60-120℃ for more than 24 hours to reduce the free water content to 10% Next, put the dried five-hole pillars into a natural gas kiln for roasting at a roasting temperature of 1300° C., roasting at a constant temperature for 10 hours, and finally cooling to room temperature to obtain an α-alumina carrier. See Table 2 for the relevant physical property data of the α-alumina carrier in this example.

[0085] (2) Preparation of catalyst: Add 60.0g ethylenediamine, 22.0g ethanolamine, 75.0g deionized water, silver oxa...

Embodiment 2

[0088] (1) Preparation of carrier: Weigh 398.0g gibbsite, 100.0g diaspore, 102.0g pseudo-boehmite, 10.0g ammonium fluoride, 7.0g barium sulfate, put them in a mixer and mix them evenly. Transfer to the kneader, add dilute nitric acid (nitric acid: water = 1:3, weight ratio, the density of nitric acid is 1.07g / cm 3 ) Until it is kneaded into an extrudable paste, put the paste into an extruding machine and squeeze it into a five-hole column, and dry it at 60-120℃ for more than 24 hours to reduce the free water content to 10% Next, the dried five-hole pillars are then put into a natural gas kiln for roasting at a roasting temperature of 1350° C., roasting at a constant temperature for 10 hours, and finally cooling to room temperature to obtain an α-alumina carrier. Table 2 shows the relevant physical property data of the α-alumina carrier in this example.

[0089] (2) The preparation of the catalyst is the same as in Example 1.

[0090] (3) The performance evaluation of the catalyst ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com