Heat-insulating film with high ultraviolet barrier property and preparation method thereof

A technology of UV blocking and thermal insulation film, applied in chemical instruments and methods, household appliances, flat products, etc., can solve the problems of UVA band blocking efficiency attenuation, inability to meet optical-grade window films, etc., and achieve good clarity and stability. , good stability, high weather resistance and high definition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] 1. Ingredients

[0050] 1.1 Preparation of UV-absorbing coating A: First weigh 4.20 parts of UV-absorbing agent hydroxyphenol triazine, 28.45 parts of Cytec one-component acrylic pressure-sensitive adhesive 1159 (45% solid content), 59.46 parts of ethyl acetate, 3.32 parts of butanone, 4.57 parts of diacetone alcohol, then mixed and stirred at room temperature for 45 minutes.

[0051] 1.2 Preparation of light-cured coating: Weigh 20.10 parts of dipentaerythritol penta / hexaacrylate, 3.54 parts of hexanediol diacrylate, 74.96 parts of ethyl acetate, and 0.83 parts of photoinitiator "1-hydroxycyclohexyl benzophenone" , 0.12 parts of photoinitiator "(2,4,6-trimethylbenzoyl) diphenylphosphine oxide", 0.45 parts of leveling agent "Tego Rad2100 reactive polysiloxane acrylate", mixed and stirred for 30 minutes A light-cured coating is prepared.

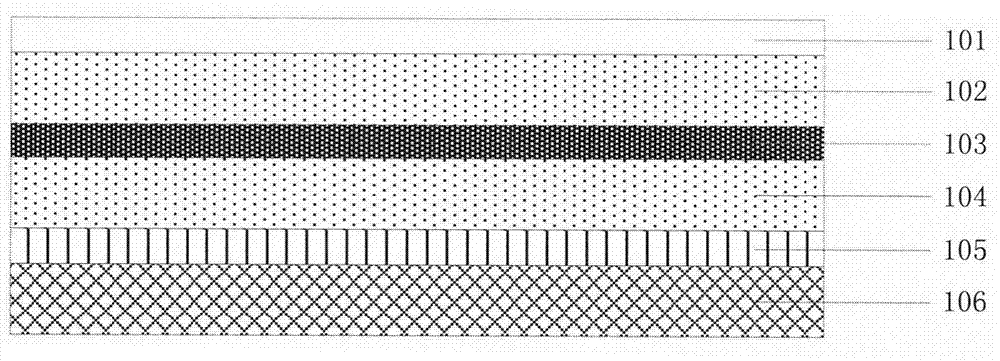

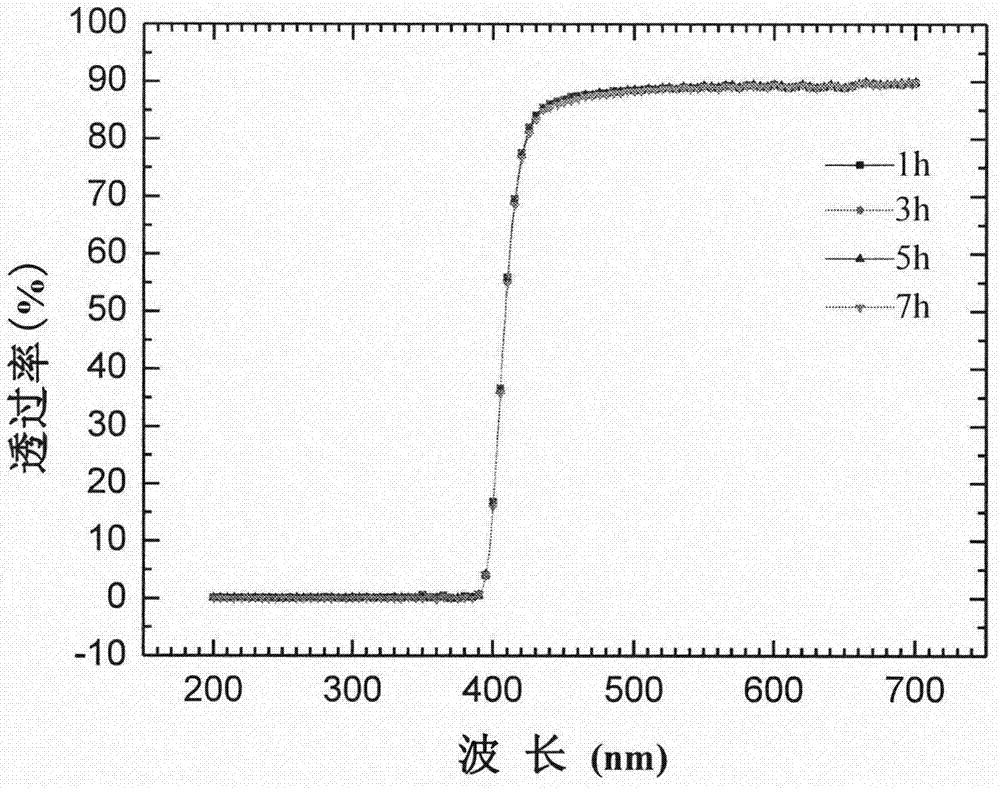

[0052] 2. Film making. Prepare a high-weather resistance, high-definition, high-ultraviolet barrier heat insulation film according...

Embodiment 2

[0059] 1. Ingredients

[0060] 1.1 Preparation of UV-absorbing coating A: Same as Example 1.

[0061] 1.2 Preparation of light-cured nano heat-insulating coating: Weigh 71.2 parts of nano-dispersion liquid, 25.12 parts of aliphatic polyurethane hexaacrylate, 1.76 parts of ethyl acetate, 0.94 parts of photoinitiator "1-hydroxycyclohexyl benzophenone", light Initiator "(2,4,6-trimethylbenzoyl) diphenyl phosphine oxide" 0.50 parts, leveling agent "Tego Rad2100 reactive polysiloxane acrylate" 0.30 parts, leveling agent "Tego Rad2300 Reactive polysiloxane acrylate" 0.18 parts, mixed and stirred for 45 minutes to prepare photocurable nano heat-insulating coating. The nano-dispersion liquid includes: 8.37 parts of dispersant, 73.47 parts of ethyl acetate, and 18.16 parts of doped tungsten oxide nanomaterials with a diameter of 50 nm.

[0062] 2. Film making. The preparation method and process of this implementation are the same as Step 1, Step 2 and Step 3 of Example 1, the differ...

Embodiment 3

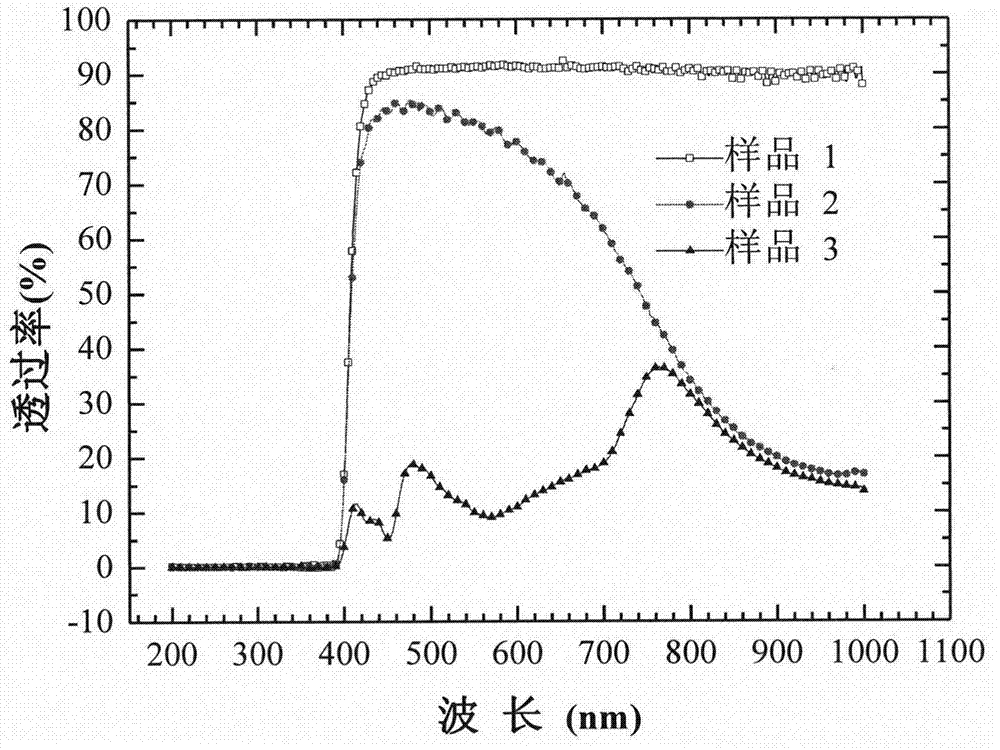

[0066] The preparation method and process of Example 3 are the same as those of Example 2, except that the base film 104 of Example 2 is replaced by a primary color film with an average visible light transmittance of 15%. The finished product that makes is sample 3, and its performance is shown in Table 1, figure 2 and Figure 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com